NTSB: ‘Poor Track Conditions’ Led to 2021 Empire Builder Derailment

Written by Marybeth Luczak, Executive Editor

Aerial view of the Amtrak Empire Builder derailment scene, Sept. 25, 2021. (NTSB Report Photograph, Courtesy of the Billings Gazette)

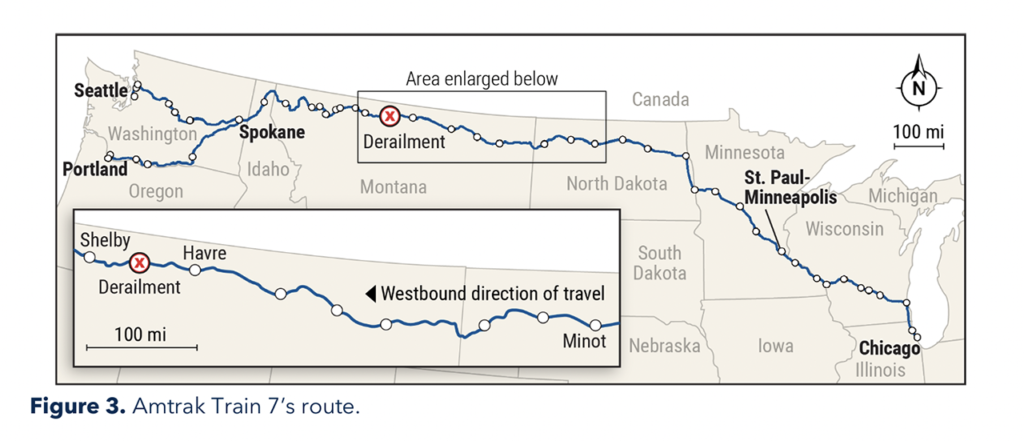

A combination of worn rail, vertical track deflection, subgrade instability and track misalignment led to the derailment of Amtrak’s westbound Empire Builder on Sept. 25, 2021, which killed three passengers and injured 49 passengers and crew members, according to the National Transportation Safety Board’s (NTSB) final investigation report, released July 27.

Contributing to the severity of the injuries “were the occupant protections that did not restrain passengers in the overturn event and the failure of the window retention systems,” the 81-page report found.

The derailment occurred in a slight right-hand curve of BNSF track approximately three miles west of Joplin, which is about 100 miles north of Great Falls, in the vicinity of Buelow, Mont. The Amtrak train carried 149 passengers and 16 crew members. It included two locomotives and 10 cars, eight of which derailed. Four cars derailed on their sides, one derailed leaning, and three derailed upright. Forty-seven side passenger window systems in the four railcars on their sides failed, according to the NTSB report. Damage to Amtrak equipment, BNSF track, and BNSF signals was estimated to be $22.5 million. (The NTSB opened the public docket to its investigation on Feb. 21, 2023.)

The report (download below) explained that a combination of track conditions caused the train to derail. “The NTSB observed three track conditions in the area of the POD [point of derailment] that were of concern: worn rail, vertical track deflection at a four-bolt rail joint, and track misalignment,” it said. “While none of the three conditions individually could be confirmed to be a condemnable defective condition because the measurements were conducted post derailment, their presence in combination led to the conditions that caused the derailment.”

Worn Rail

“In this accident, because of the wear on the rail, the NTSB observed evidence that the wheel flanges were riding on top of the joint bar,” the report noted. “This type of contact creates nonuniform forces that result in unequal load distributions into the rail system. In addition, rail joints that are loose and not strongly attached to the crossties will cycle up and down as trains move over them, further disturbing track conditions. When a wheel flange departs the normal wheel-rail interface and rides up onto a joint bar in curved track, the forces the train experiences while negotiating the curve can be excessive and nonuniform, resulting in a wheel climb derailment (Wu and Wilson 2006). The NTSB concludes worn rail at the four-bolt rail joints allowed wheel flange contact; this created a condition that resulted in nonuniform and excessive forces on the train and unusual load distributions into the rail, contributing to the wheel climb derailment.”

The report noted that NTSB “has long recommended the FRA [Federal Railroad Administration] create standards related to rail wear. In July 1980, tank cars carrying hazardous materials derailed in Muldraugh, Kentucky. Two tanks carrying vinyl chloride were punctured and their contents burned. An examination of the track curve leading to the derailment disclosed excessive wear. As a result of that investigation, the NTSB recommended the FRA create regulations that designate the limit of acceptable rail wear (NTSB 1981).”

According to the report, “[h]ad the Federal Railroad Administration established rail wear limit regulations, that likely would have required replacement of the worn rail before there was wheel flange contact with the four-bolt joint bar.”

Vertical Track Deflection

“Forward-facing image recordings of Amtrak Train 7 moving through the curve showed that the train exhibited sudden, abnormal movements such as rolling, yawing, and swaying consistent with poor track conditions,” according to the report. “The NTSB’s investigation found that the east joint on the north rail had a vertical track deflection of 2 inches and the west joint had a vertical deflection of 1 1/8 inch. This type of track condition would contribute to the sudden, abnormal movements that were observed in the forward-facing image recordings. As Amtrak Train 7 traveled over the vertically deflecting four-bolt rail joint bars, the load distributions would have changed, imparting undesirable loading conditions into the track. Both four-bolt rail joints exhibited notable deterioration at their rail ends. As a result of these conditions, Amtrak Train 7 rocked and swayed, ultimately unloading the wheels on the south rail in a wheel climb derailment. The NTSB concludes that the vertical track deflection at the east and west four-bolt rail joints contributed to wheel unloading and the wheel climb derailment.”

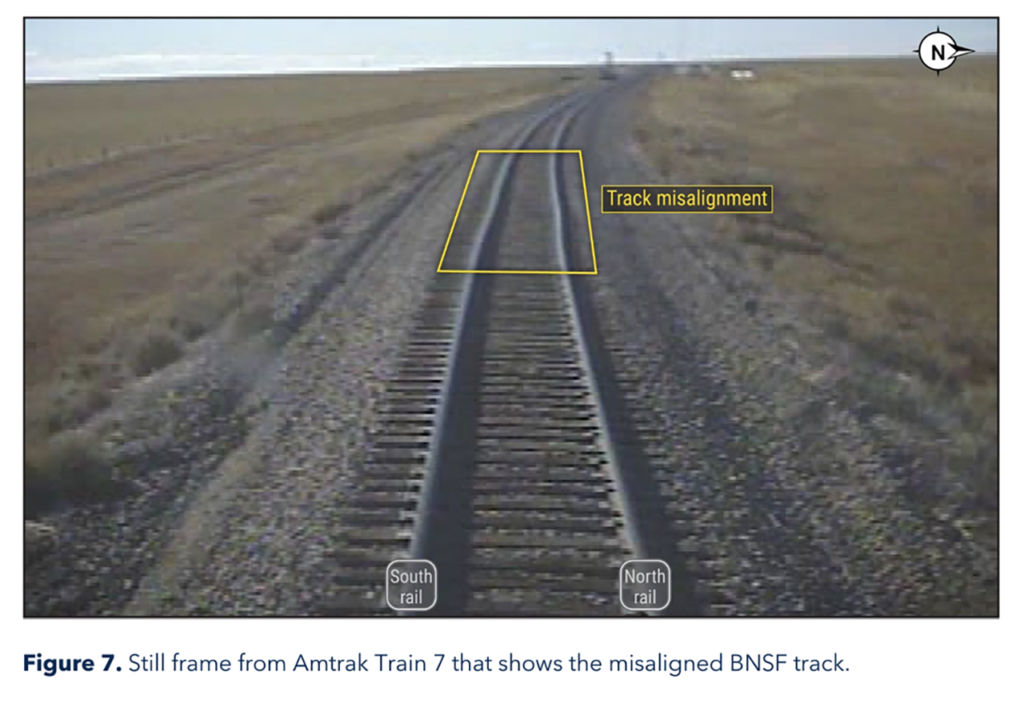

Track Misalignment

“Data captured from the forward-facing image recordings of the three earlier trains, beginning 3 hours and 19 minutes before Amtrak Train 7, showed right and left rolling, yawing, and swaying of the trains as they traversed the track,” according to the report. “Further, data from these trains showed a progressively worsening track misalignment in the derailment curve with the north and south rails shifting further to the left as each train traversed the track. The NTSB reviewed the forward-facing image recordings from Amtrak Train 7 to observe how the misalignment had progressed. By using the still images from the recordings, the NTSB estimated that as the train traversed the derailment area, the track had laterally shifted in the curve between 2 and 4 inches. Forward-facing image recordings show abnormal train performance as Amtrak Train 7 traveled through the misalignment, after having just traveled over vertically deflecting four-bolt rail joints while its wheel flanges rode atop a joint bar. These recordings show the locomotive shifted violently to the left and then to the right, then back to the left, and the train derailed as this motion progressed back through the train. Therefore, the NTSB concludes that Amtrak Train 7 derailed immediately after traveling through a track misalignment in the accident curve.”

Subgrade Instability

The report also addressed subgrade instability. “On September 15, 2022, NTSB investigators and representatives from BNSF’s engineering department returned to Joplin for additional evaluation of the accident curve, including a walking inspection,” it said. “The NTSB noted that since the derailment, BNSF had conducted extensive track renewal in the curve, in addition to the crosstie and surfacing work that had been done before the derailment. BNSF replaced both the north and south rails with 141-pound CWR, which eliminated all rail joints in the curve, and reinforced some of the crossties. BNSF then surfaced the track after this work to obtain proper track geometry … [T]he NTSB noted a segment of track that exhibited vertical movement and subgrade instability near the earthen fill that contained the culvert that encompassed the POD and extended about 78 feet west and about 200 feet east. This area had been identified because of the disturbed ballast between the crossties that had showed signs of movement. Track always demonstrates some degree of vertical movement. However, during the September 15, 2022, walking inspection, the NTSB noted that while a freight train was traversing the fill, the track was moving more significantly in a vertical direction under the loads put on the track by the train wheels than on the other areas of the track. The NTSB concludes that there was an ongoing unresolved subgrade instability issue on the derailment curve.”

Report Conclusions

In addition to the track conditions outlined above, the report found that:

- “BNSF Railway’s signal and train control systems; the performance, training, or experience of the Amtrak engineers; or the mechanical condition of the Amtrak vehicles” did not contribute to the derailment of Amtrak Train 7.

- “Had the Federal Railroad Administration defined specific allowable limits for combinations of track conditions, the conditions on the BNSF Railway track in Joplin would likely have been identified and warranted remediation before the derailment occurred.”

- “Given the rapid degradation of track conditions on the day of the derailment, it is unlikely that the track surface deviations at the track would have been detected through the current periodic track inspection process required under Federal Railroad Administration regulations.”

- “Had trains with a vehicle/track interaction-equipped locomotive traversed the accident curve on the day of the derailment, the deteriorating track conditions could have been identified and real-time notification provided to BNSF Railway, affording the opportunity for BNSF Railway to take action to mitigate the danger of misaligned track.”

- “The expanded use of vehicle/track interaction monitoring systems across Class I and intercity railroads to detect track geometry conditions earlier could reduce the likelihood of train derailments.”

- “The continuously welded rail installation requirements of Title 49 Code of Federal Regulations 213.119 (c)(2) should apply to all continuously welded rail joints.”

- “The track inspector likely could not perform a required walking inspection of the derailment curve due to his assigned workload to inspect an excessive amount of track.”

- “BNSF Railway’s lack of proactive management controls to prohibit work assignments likely to cause fatigue and workload risks for safety-related employees is an indication of a shortcoming in its safety culture.”

- “A comprehensive Fatigue Risk Management Program must fully recognize all the demands placed on employees to perform their jobs, including the tasks, responsibilities, duties, and hours worked, and must make necessary modifications to the job and/or scheduling to mitigate associated risks.”

- “The Federal Railroad Administration’s restructured Focused Inspection Program would benefit from both automated and walking inspections to ensure an improved understanding of the condition of the track beyond what can be known by only automated inspections.”

- “This derailment demonstrates that there is a need for performance standards for window retention systems to prevent passenger ejections from railcars during derailments.”

- “The use of compartmentalization did not protect the occupants in the overturned railcars from injury during the derailment and overturning of the railcars in the Joplin derailment.”

- “The Federal Railroad Administration’s occupant protection standards do not provide adequate protection from passenger injuries likely to occur during derailments and overturns due to their reliance on compartmentalization as the basis for the standards.”

As a result of its investigation, NTSB issued six new safety recommendations addressing limitations of track inspection practices, autonomous monitoring systems and treatment of maintenance rails installed. They are:

To the Federal Railroad Administration:

1. “Require a limit for maximum acceptable rail wear. (R-23-1)”

2. “Establish interoperability requirements among railroads to implement a process in which a predetermined critical alert from a vehicle/track interaction system would require an immediate slow order that remains in place until a walking inspection is performed and, if needed, subsequent repairs are completed. (R-23-2)”

3. “Require that the continuously welded rail installation requirements of Title 49 Code of Federal Regulations 213.119 (c)(2) be applied to all continuously welded rail joints, including those added to install maintenance rail. (R-23-3)”

To all Class I and intercity passenger railroads operating on main line tracks, including Amtrak and the Alaska Railroad:

1. “Equip all trains with an autonomous monitoring system, such as vehicle/track interaction, to detect track geometry defects. (R-23-4).” The report noted that “autonomous monitoring systems that are in limited use on passenger and freight rail vehicles have the ability to monitor track conditions and provide real-time condition monitoring that could be used for early identification and mitigation of unsafe track conditions.” Both BNSF and Amtrak already have such systems in limited use, it said.

To BNSF:

1. “Conduct additional comprehensive geotechnical evaluations throughout the derailment curve fill area to determine the cause of the subgrade instability. (R-23-5)”

2. “Once the geotechnical evaluation has been successfully completed and the cause of the subgrade instability has been determined, make appropriate repairs to stabilize the track and prevent excessive movement of the track structure. (R-23-6)”

The NTSB also reiterated recommendations that address retention of passenger windows in railcars and the adequacy of compartmentalization in railcars.

“This tragedy is a powerful reminder that there’s no substitute for robust track inspection practices, which can prevent derailments by identifying track conditions that may deteriorate over time,” NTSB Chair Jennifer Homendy said July 27. “I implore track owners, who are responsible for the safety of their routes, to ensure inspectors have the time, support, and resources needed to do their work, which is essential to rail safety.”