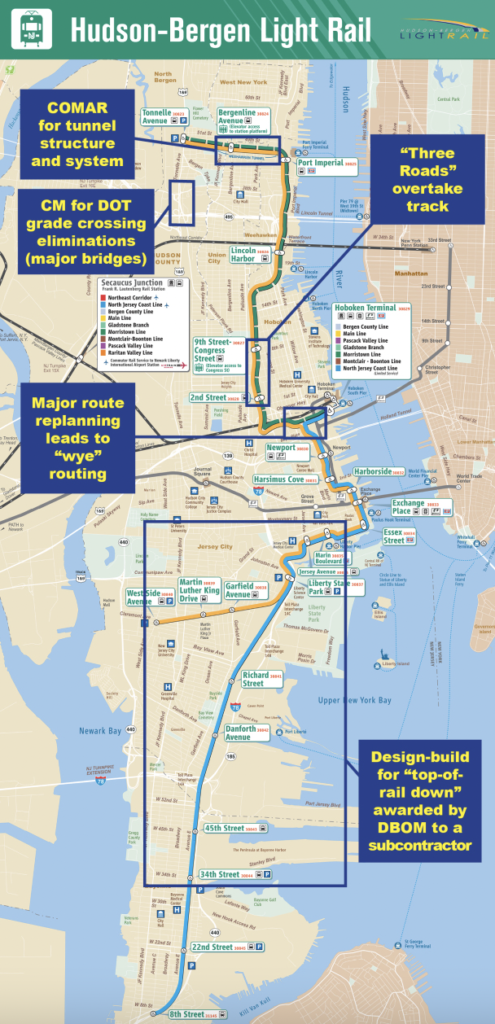

Hudson-Bergen Light Rail: DBOM and More

Written by Alfred E. Fazio, Alfred E. Fazio, P.E., Contributing Editor

(Wikimedia Commons/King of Hearts)

RAILWAY AGE, NOVEMBER 2023 ISSUE: Why New Jersey Transit’s Hudson-Bergen Light Rail (HBLR) is a DBOM (Design-Build-Operate-Maintain) model deployment.

NJ Transit’s HBLR DBOM, originally led by Raytheon and Kinkisharyo (with Washington Group ultimately assuming Raytheon’s role) resulted in a fully built and equipped system, including light rail vehicles, a major shop and yard, and a control center in less than 41 months after award of an NTP (notice to proceed), all based upon an original 30% design.

Importantly, service quality also set a gold standard, with high quality and innovative practices employed from day one of revenue operations. Not well known is that the HBLR program went well beyond the limits of the HBLR system and employed methods of delivery other than DBOM for various major projects within the Umbrella Program.

The current revised interest in creative or alternative delivery schemes for transit systems seeks to reduce the time and cost of major extensions to existing ones or to deployments of entirely new systems. Amtrak, for example, has expressed major interest in employing COMAR (Construction Management at Risk), and the New York MTA C&D group is actively employing Design-Build on major programs. As discussed in this article, these projects comprising the larger HBLR program included a sampling of these various techniques.

OTHER COMPONENT PROJECTS

The geographic extent of the HBLR program included Newark/Bloomfield, N.J., on Newark Light Rail (NLR) and western Bergen County:

1. Newark City Subway (NCS) Design-Build: As part of its overall light rail Program, NJ Transit was converting the NCS, which was essentially a streetcar system operating on a roughly 4-mile exclusive right-of-way, into a full-fledged LRT system, NLR. A major component of this work was a one-mile extension to Bloomfield and construction and equipping of a new yard, VBF (Vehicle Base Facility) and control center. The latter was accomplished as a D-B project within the HBLR program. This effort included direct support to commissioning the new work.

2. Newark LRVs: The Build criteria for the HBLR light rail vehicles were consistent with and largely driven by NJT’s desire to standardize. The clearance and curve radius capability for the HBLR vehicle were, for example, based upon the limitation of the NCS Penn Station Newark loop tracks. As part of HBLR, approximately 20 LRVs were supplied directly to NJT; slight modifications included use of different cab signal aspects (MAS at 50 mph) and outfitting with PCC wheels, rather than HBLR AAR wheels.

3. Grade Crossing Elimination, Professional Services for Construction Management: Following the opening of the Bayonne and West Side lines to the south, the next extension of HBLR was designated on the northern line (Weehawken and Tonnelle Ave.). This route was to use the alignment of CSX’s former New York Central busy West Shore freight main line. All freight would all be removed to a parallel CSX line to the west; however, the density and length of freight trains mandated that major grade crossing elimination be completed first. Under the HBLR contract, a CM services project was awarded to Raytheon/Twenty-First Century Rail (TFCR) to manage and expedite this work.

4. Design/Build subcontract to TFCR: While TFCR had both the capability and intent of self-performing much of the design and install/construct, mobilization and timing considerations led to the awarding of a D-B subcontract for portions of the IOS (Initial Operating Segment). The scope included all items—subgrade, track, under-grade bridges, i.e., all work from TOR (top-of-rail) down. This action permitted Raytheon engineering to focus on design of rail systems and procurement of long lead equipment (substations, signal equipment, catenary). This expediate was restricted and important to achieving the highly accelerated schedule mandate (40 months from NTP to revenue service) for the initial 5-mile segment.

5. COMAR: The HBLR was designated to turn geographically west from Hoboken and utilize the existing 100-year-old tunnel to access Tonnelle Avenue and areas to the west of the Palisades rock formation. The tunnel would be improved, widened in places, and tunnel systems (lighting, ventilation and other line equipment) installed. In addition, a major underground station was to be constructed at roughly the tunnel midpoint at a depth of 180 feet. The design for the line equipment and station, and vertical bore from the surface to the tunnel floor (required for elevators, vent shafts, emergency stairs and conduit runs) was not part of the DBOM. Rather it was fully designed by a separate engineering firm. The design of the rail systems was under the DBOM. The construction of the independently designed scope (executed as a D-B-B) was awarded to a third-party contractor, jointly selected by NJT and TFCR, as a subcontractor to TFCR. There were a variety of execution challenges, which included site access within the tunnel and labor issues. The subcontractor was not local and was unfamiliar with New Jersey labor practices and technical integration, e.g., station and ventilation SCADA to HBLR Supervisory Control. Fortunately, these issues were resolved without legal involvement.

6. Operations Planning/Professional Services: Subsequent to the award of the DBOM, a major route realignment occurred with respect to the entry into NJT’s Hoboken Commuter Rail Terminal. This required a joint alignment design and operations planning exercise involving NJT, TFCR, and NJT’s Design Operations Planning consultants. The result was the creation of the Hoboken Wye (which is within the Jersey City limits) and bifurcation of the line. This new wye would adversely affect line capacity and complicate the route service structure. The DBOM supplier assisted in configuration planning and led the operational planning effort that determined the revised transit capacity of each route through the wye, and the revised three-route (compared to the original two-route) service plan. TFCR also developed and implemented the highly successful Bayonne Flyer express service.

7. Safety Certification: All new transit systems and extensions to existing systems receiving federal funds require full Safety Certification by the operator (referred to by APTA as the Rail Transit System or RTS), in compliance with FTA and State Safety Oversight guidelines. The IOS was self-certified by TFCR, a first by a private operator. This caused some liability concerns within the TFCR organization, all of which were resolved. It should also be noted that subsequent segments were formally endorsed for certification by TFCR, with actual certification by NJT.

METHODS AND CHALLENGES

As in any mega-program, challenges abounded. A few of these could be directly traced to the specific deployment scenario employed for the involved project. Those contemplating innovative methods would do well to conduct an extensive review of such delivery-specific issues.

On the VBF for Newark, a relatively conventional D-B, major scope creep occurred as the owner made several changes to the configurations of the yard and shop. This resulted in the D-B overrunning the budget, which in turn led to a potential dispute and possibly a formal claim. The DBOM contract included an Equitable Adjustment Clause primarily directed at the unknown risks that would be assumed by a private entity operating on urban mass transit systems for the specified 15 years.

Under this clause, confidential documents associated with bid preparation were placed in escrow. Presumably, upon a request by the DBOM supplier for an adjustment, these documents would be considered. Ironically, this clause was enacted by NJT when the agency requested a reduction in the annual O&M (operations and maintenance) price. TFCR agreed to such a reduction without formally invoking the equitable adjustment actions in consideration for being made whole on the loss incurred in the Newark D-B project.

There was a more serious and difficult situation challenge on the COMAR employed for the tunnel subcontract. The contractor selected was chosen based upon its expertise in use of vertical bore technology in rock. Unfortunately, insufficient due diligence was performed on that company’s ability to organize and manage major work in a multitude of technical areas other than vertical bores (e.g., ventilation and SCADA), and in its ability to function as a GC (general contractor) on a technically difficult and spatially confined project. Design difficulties were also discovered, such as a lack of adequate drainage over the entire length of the one-mile tunnel, and an undersized elevator motor. While NJT ultimately accepted the cost of the design problems, TFCR was required to muddle through the other tunnel work, in many cases going beyond what would normally be expected of the CM (contract manager) in a COMAR project.

CONCLUSION

The end results of the HBLR DBOM were a well-designed and well-built HBLR and NLR, both of which are considered benchmarks from an operating perspective. Those who are contemplating use of any of these specialized project delivery methods are well-advised to independently investigate this and other examples. The challenges and failures are of particular relevance. One often learns more from failure than from unmitigated success.