Timeout for Tech: Railway Bridges

Written by Gary T. Fry, , Ph.D., P.E., Vice President, Fry Technical Services, Inc.; and W. N. Marianos, Jr., Ph.D., P.E., Structural Engineer

The 133-year-old Merchants Bridge, which spans the Mississippi River at St. Louis and links Missouri and Illinois, officially reopened to rail traffic Sept. 15, following completion of a $222 million replacement project. Owned and operated by the Terminal Railroad Association (TRRA), the bridge serves six Class I railroads and Amtrak. (Courtesy Walsh Construction and Trey Cambern Photography)

RAILWAY AGE DECEMBER 2022 ISSUE: Welcome to “Timeout for Tech.” Each month, we examine a technology topic that professionals in the railway industry have asked to learn more about. This month, I am joined by co-author and structural engineer W. N. Marianos as we consider railway bridges.

By 1870, at least 50,000 miles of railway existed in the U.S. By 1890, railway mileage had more than tripled, exceeding 160,000 miles. Roughly 110,000 miles of railway had been built in those 20 years—enough to encircle the Earth 4.5 times!

And, of course, many bridges were built. Bridges are essential to a railway, allowing us to build optimally routed tracks that cross major rivers and small streams, deep canyons and shallow swales (Figures 1 to 4, below). Railway bridges come in many span configurations often incorporating multiple types in a particular bridging solution—arches, girders, trusses, and trestles. They have been made from a variety of different materials—wrought iron, steel, concrete, stone, wood, and combinations of these. As dictated by the local needs along the railway, one bridge to the next can vary greatly in length from a short, single span of less than 15 feet to a multi-mile trestle comprising hundreds of spans. It can be estimated that roughly 2,700 total miles of bridge spans were built between 1870 and 1890—a little under 2% of the 160,000 miles that comprised the U.S. railway network at that time.

We will focus our attention at the “Gateway to the West,” St. Louis, Mo., and describe the essential features in the service life of a successful supercentenarian railway bridge that, up until its replacement this year, crossed the Mississippi River.

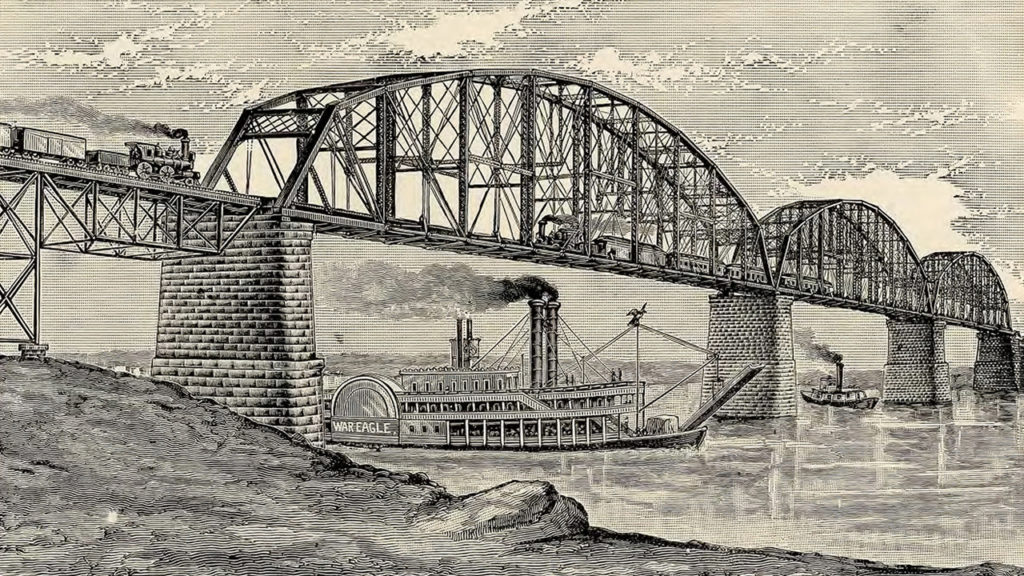

On March 18, 1890, the St. Louis Merchants Exchange celebrated the opening of its brand-new double-track railway bridge over the Mississippi River at St. Louis—the Merchants Bridge (Figure 1, above). Details in Figure 1 highlight some of the compelling features of the bridge. First and foremost, the bridge provides uninterrupted passage of trains across what would otherwise be a substantial barrier—in this case, across 1,800 feet of fast-flowing Mississippi River. The illustration depicts a westbound passenger train on the middle of the bridge as it heads into St. Louis and an eastbound freight train just entering the bridge on the adjacent track. Looking at the image more closely, not only does the bridge accommodate two trains, simultaneously, but it does so without interrupting traffic on the river below where we see a steamship and a tugboat cruising the river unimpeded by the spans—a marvel of large-scale technology indeed!

Merchants Bridge was not the first Mississippi River crossing at St. Louis. That distinction belongs to the monumental Eads Bridge, which opened in 1874. But within 15 years after the Eads Bridge opening, interest grew in building a second bridge at St. Louis. An 1888 brochure promoted the “Merchants Bridge” as a “pressing necessity to the best interests of St. Louis,” to be located in north St. Louis. The brochure called for leading merchants, businessmen, manufacturers, and the public to buy stock in the bridge company. Money was raised, and detailed design work was in progress by the end of 1888. The bridge was completed at a cost of $3 million in 1890. George Shattuck Morison, one of the leading bridge engineers of the time, designed the bridge.

In March 1889, Morison addressed the St. Louis Commercial Club. He recounted the history of American bridge engineering to that date as driven by developments in construction materials. He discussed the relatively recent introduction of structural steel for bridge construction, and commented that “in a few years, wrought-iron will be as much a thing of the past as homespun cloth.” Morison also observed that bridges built only 20 years earlier were being replaced, due to the increased size and weight of railway rolling stock: “The freight car of 1870 fully loaded weighed from 19 to 22 tons; the same car of today [1889] weighs from 32 to 45 tons.” Similarly, he noted locomotive weights increasing from 50 tons in 1870 to 75 tons at the time of his speech, and projected similar future increases in loads.

Within 12 years, Morison’s expectations of increased train weights on bridges were realized. In 1902, the first of many strengthening projects on Merchants Bridge began. The new design loading for the strengthening project was a steam locomotive with 25-ton axle loads. As in many truss spans, strengthening was needed in the floor systems (the components directly supporting the rail and ties) and in the truss web members (the vertical and diagonal components of the trusses). The 1902 strengthening installed two new, stronger beams (called stringers) to support one track and added the two removed stringers under the other track to bolster its support. For the next 120 years, the bridge had two large stringers supporting the westbound track, and four smaller stringers supporting the eastbound track. Reuse of material was common at this time. Many old bridge plans have notes that components will come from other structures.

Morison died on July 1, 1903. Over the following decades, locomotive weights continued to increase. Records show bridge engineers continually assessing the capacity of Merchants Bridge and working on ways to keep it in service. In 1930, for example, some original bracing members were removed for material testing to better determine actual member capacities. As part of this assessment, exacting measurements of truss deflections under known train loads were also made. By this time, the test locomotives had 32.5-ton axle loads. Ongoing strengthening work included reinforcing truss diagonal members with “hairpins” fabricated to fit around the existing components.

By the mid-1930s, design loads for railway bridges were approximately twice the load that Morison had used in the original design of the Merchants Bridge. This was also true for other spans in the general railway bridge population. While some bridges were replaced, strengthening projects and refined analyses of actual bridge capacities resulted in many others remaining safe for continued service. In addition, operating restrictions, such as slow orders and restricting trains meeting other trains on double-track spans reduced the maximum loads some bridges would need to carry. But these restrictions compromise the value of the bridge as an asset, often making it a candidate for eventual replacement.

In 1889, Morison had speculated that future increases in train loads would lead to rapid replacement of bridges then being constructed. By the late 1930s, it appeared that his projection would be true, but a major change in locomotive design interrupted the ongoing increase in railway bridge design loads. During the 1940s, the introduction of diesel locomotives reduced the maximum loading applied to railway bridges, because of their significantly lighter axle loads, as well as lower dynamic effects from the absence of reciprocating forces from the drivers. This change extended the remaining useful life of many bridges.

While extending the life of these bridges postponed replacements, it added to the ongoing maintenance costs for the structures. Corrosion of steel bridges is a perpetual concern. For example, many components on the Merchants Bridge were repaired and replaced due to rust.

Also, accidents happen. River traffic is active on the Mississippi below the Merchants Bridge. Vessel strikes of piers and even of the superstructure occurred many times over the life of the bridge. The massive piers typically could shrug off impacts. The superstructure, even though more than 50 feet above the high-water level, had to be repaired several times due to strikes, typically from booms of barge-mounted cranes.

Although the weights of diesel locomotives were lower than that of the steam engines they replaced, the weight of typical freight cars increased in the diesel era, especially through the 1970s and 1980s. Unit trains carrying commodities such as grain and coal were introduced. Double-stack container trains also were brought into service.

These changes affected railway bridges in several ways. Double-stack operation required increasing clearances on many bridges and tunnels. On the Merchants Bridge, the truss portal braces and sway frames were raised in the mid-1980s to allow double-stack traffic passage.

The increased car weights resulted in car axle loads that could exceed those of locomotives. Since 1995, a fully loaded freight car in the U.S. is permitted to weigh 143 tons (“286K”), yielding 36-ton axle loads. Comparatively, a six-axle diesel locomotive weighs roughly 200 tons, yielding 33-ton axle loads. Because of this, the number of significant load cycles per train significantly increased.

When Merchants Bridge was constructed, the significant load cycles per train typically were limited to those caused by the locomotives. With increasing car axle loads, however, each car could cause one or more significant load cycles depending upon span length. This phenomenon impacted many aspects of the rail system. For bridges, it caused a rapid increase in fatigue damage, renewing concerns over the remaining safe lives of the structures.

Bridge owners addressed the fatigue concerns in several ways. For example, bridge members most affected were reinforced, and inspection frequency was increased, especially for bridge components susceptible to fatigue and fracture problems. In addition, instrumentation was installed on bridges to measure dynamic member loads under traffic. This information was used to develop refined estimates for remaining fatigue life of bridge members.

Loads from earthquakes can also be a problem for railway bridges. Research conducted during the 1970s though the early 2000s greatly improved understanding of regional seismic risks in the U.S. As a result, seismic vulnerability became an increasing concern in the St. Louis area. The city is located upriver of New Madrid, Mo., the approximate epicenter location of major earthquakes in 1811-1812.

Ultimately, by 2010, it became evident that the Merchants Bridge was near the end of its serviceable life. The ongoing operating restrictions due to bridge capacity and available geometric clearance for equipment, the increased inspection and repair requirements, and the benefits of having seismically resistant railway crossings of the Mississippi River in the area led to a decision to replace the bridge.

The replacement bridge was designed as a double-track, ballasted deck structure accommodating current maximum design train loading and vertical and horizontal clearance requirements. The replacement of the original bridge was completed in the fall of 2022, with the masonry piers encased in reinforced concrete for seismic resistance.

The service history of the Merchants Bridge—train loads, repairs, strengthening, retrofitting, and service restrictions—is generally representative of that experienced by many bridges of its era. With appropriate actions taken by generations of engineers, these bridges have safely supported trains crossing their spans for well over 100 years—including trains much larger and heavier than considered in the original bridge design documents. Around the U.S., several railway bridges built in the 1890s and earlier have supported revenue service train operations well into the 21st century. But few, if any, have done so without strategic engineering interventions like those used on the Merchants Bridge in St. Louis. With increasing frequency, these bridges are being replaced with new structures that incorporate lessons learned from our experiences maintaining their predecessors. Undoubtedly as these newest bridges age, they will eventually require the expert ministrations of talented bridge engineers who are likely yet to be born.

Dr. Fry is Vice President of Fry Technical Services, Inc. He has 30 years of experience in research and consulting on the fatigue and fracture behavior of structural metals and weldments. His research results have been incorporated into international codes of practice used in the design of structural components and systems, including structural welds, railway and highway bridges, and high-rise commercial buildings in seismic risk zones. He has extensive experience performing in situ testing of railway bridges under live loading of trains, including high-speed passenger trains and heavy-axle-load freight trains. His research, publications, and consulting have advanced the state of the art in structural health monitoring and structural impairment detection.

Dr. Marianos has more than 35 years of railroad bridge design experience. He has designed dozens of railroad bridges of various types and spans over his career, including many steel structures. He has conducted investigations of distressed structures and prepared repair plans for them. His consulting clients include most of the U.S. Class I railroads, many contractors and a variety of consulting engineering firms. Dr. Marianos is a licensed professional engineer in 26 states.