May the Clamping Force Be with You

Written by Carolina Worrell, Senior Editor

L.B. Foster

RAILWAY AGE, OCTOBER 2023 ISSUE: Rail fastening system technology continues to evolve, delivering a tight hold and longer track life in heavy-haul freight, high-speed passenger rail and transit applications across North America and beyond.

Gauge-holding capability, resiliency, noise reduction, ease of installation and maintenance, low life-cycle cost, safety: Railroads rely on fasteners with these qualities from such companies as Progress Rail, Kawasaki Track Technologies, MxV Rail, L.B. Foster, Howmet, Lewis Bolt & Nut Company, Pandrol, J. Lanfranco and Vossloh North America to perform reliably and safely under traffic ranging from heavy-haul freight to high-speed passenger rail to transit. To meet these requirements, suppliers continue to make incremental updates to their system technologies. Railway Age contacted fastening system suppliers to find out about their latest technologies. Following is a roundup of offerings from those which responded to our inquiries.

Kawasaki Track Technologies

Kawasaki Track Technologies

“Technology that improves safety and efficiency continue to have a strong interest in the marketplace,” says Kawasaki Track Technologies. “We continue to utilize the latest machine vision and machine learning technologies to inventory fasteners and detect potentially defective fasteners.” Following a successful 2022 test in Japan, the company in February 2023 began testing a track fastener monitoring technology in North America. While installed on a locomotive, it will “capture high-resolution pictures and provide the necessary data for Kawasaki to utilize machine learning algorithms to identify potential track fasteners that need to be inspected and repaired.” Kawasaki employs cameras and global positioning sensors to identify potential defects. When the system is complete, it will provide near real-time exceptions to its customers. Kawasaki plans to offer production systems for locomotives installations in early 2024. This technology, the company notes, will “continue to expand Kawasaki’s autonomous track inspection technology to enhance railroad safety and operating efficiencies.”

Progress Rail

Progress Rail, a Caterpillar company, supplies a full line of fastening systems for heavy-haul and transit railways with options such as the e-Style Clip, the resilient Loadmaster DF (direct fixation) for timber ties and the ADFF55 high attenuation direct fixation fastener. For example, according to General Manager of Fastener Solutions Hakan Eksi, the DF Block System “dramatically improves the quality of direct fixation fastener installations for standard and high attenuation units” and “eliminates the risk of irregular support surface conditions such as concrete honeycombs and improper elevation setting of a concrete embedded insert.”

On the Los Angeles Metro Westside Purple Line Section 1, the DF Block system “has reduced installation time with less material handling and fewer personnel required for the same work,” Eksi notes. It improves life expectancy of DF units, reduces maintenance and provides a significant initial installation savings as compared to the 30-plus-year-old top-down construction technique.

MxV Rail

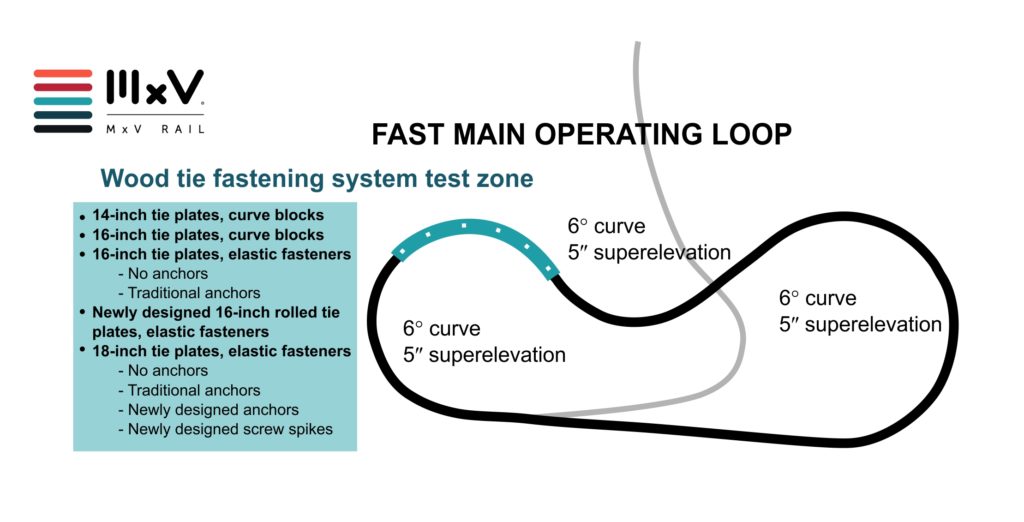

The fastener test zones at MxV Rail’s new Facility for Accelerated Service Testing (FAST) include various designs and configurations of tie plates, fasteners, spikes, and anchors, according to Principal Investigator Yin Gao. To evaluate performance in a challenging environment, Gao says the fastener test zones have been installed on a six-degree curve with a five-inch superelevation and experience tonnage accumulation from a train of loaded 315,000-pound GRL cars operating at 40 mph.

The primary fastener test zones at FAST are listed in the figure (above). Elastic fasteners are often used on track located on grades with a high degree of curvature since they provide greater resistance to rail rollover and gauge widening, Gao says. Curve blocks also provide rail rollover resistance while allowing rail more freedom to expand and contract longitudinally.

According to Gao, newly designed anchors and screw spikes are being tested to evaluate their service life and performance in comparison to traditional components. “The railroad industry will benefit from improved understanding of the longevity and potential failure modes of these fasteners,” Gao adds.

Vossloh

Vossloh’s new M-generation clamp is born from targeted research and development around vehicle-track interaction, resulting in significantly higher natural frequency, the company tells Railway Age. The M-generation tension clamps have many other design benefits.

Compact in design, the outwardly curved spring arms “are the most striking feature of the new tension clamps.” Their geometry, which resembles a cursive “M,” “provides both a larger contact area to the rail base (reduced contact stress) and increased three-dimensional fatigue strengths.” The wide-spread spring arms also increase fastening torsional resistance, “improving lateral track stability and buckling resistance without disturbing the ties and ballast or requiring speed restrictions.”

“A hot topic for railroads today is track buckling; torsional resistance by using the M-generation can be more than 100% higher than traditional fastening systems,” according to Vossloh. A new micro-steel alloy, low stress bending and an enhanced hardening process contribute to improved performance and decreased CO2 emissions. This, Vossloh says, “lowers life cycle costs on a comparative basis and allows the use of more elastic rail fastening systems to further increase robustness and safety.”

Vossloh says the M-generation is “100% compatible with existing rail fastening systems and combines properties of several previous clamp designs, reducing complexity in track and spare parts stock.” The M9 is made for U.S. rail infrastructure. Appropriate for almost all North American applications, Vossloh says it has been installed in “multiple demanding Class I revenue service locations over the past two years to confirm its operational capability and will continue to roll out more widely to commuter lines.”

Lewis Bolt & Nut Company

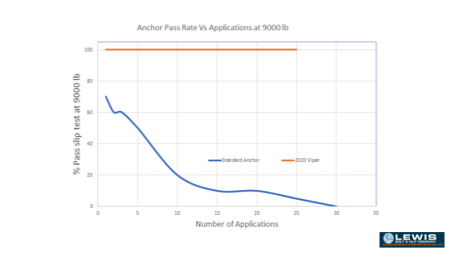

Lewis Bolt & Nut Company’s most recent product launch is the Viper-1® drive-on anchor, says Senior Assistant Vice President of Sales George Apostolou, who adds that the Viper-1® “exceeds American Railway Engineering and Maintenance-of-Way Association (AREMA) Chapter 5, Section 7.1.4 requirements and has a minimum holding power of 9,000 pounds vs. 6,000 pounds (AREMA 7.1.4, Part B).”

In addition, the Viper-1® “has a much higher re-application rate than any current anchors on the market,” Apostolou says. “The anchor can be removed and reapplied multiple times because of improved stiffness in the design of the anchor jaw.” Another key benefit is “the larger bearing surface against the tie. The Viper-1® boasts 75% more bearing surface than standard drive-on anchors. This results in increased tie life preventing movement and damage to the tie surface. In addition, Viper-1® offers an increased life cycle that is designed to last the life of the rail.”

“Market conditions have remained strong year-to-date in 2023, and with the adoption of the Viper into the market we expect that to continue into 2024,” notes Apostolou. When asked to comment on the company’s overall business outlook regarding grant money currently available, Apostolou said that although the company “does not see any grant money directly, our sales do benefit from this its availability. We just quoted a large project for Genesee & Wyoming’s Rapid City, Pierre & Eastern Railroad (RCPE).”

L.B. Foster

L.B. Foster Company has been supplying vulcanized rubber bonded DF fastening systems to transit agencies across the U.S. and Canada for more than 40 years. The company’s Transit Products Division “specializes in the design and development of noise and vibration mitigation and electrical isolation technologies.”

L.B. Foster offers a line of more than 50 fastening systems, each “uniquely designed” to offer varying stiffness and resiliency, rail seat width and height accommodations, lateral adjustment, and anchoring locations in a “single, easy-to-install unit,” the company says. “Our engineering team partners with our customers to design new fastening applications to meet their specifications and design requirements,” L.B. Foster tells Railway Age.

Additionally, L.B. Foster’s research and development team is engaged in prototyping and testing alternative materials and manufacturing processes. “This ongoing effort aims to continually enhance the performance and lifespan of our fastening systems,” the company tells Railway Age. “Our teams are diligently researching adaptable methods to improve noise and vibration mitigation, aligning our solutions with the evolving needs of our customers and the changing landscape of the transit sector. Additionally, we are working on advanced aluminum contact rail designs that promise to deliver superior electrical performance for every pound of installed weight.