HFC Developments Accelerating

Written by Gordon V. Jefferson, President; and Jenalea Smith, Associate, Hydrogen Fuel Cell Train Association

Alstom Coradia iLint HFC regional trainset demonstration in Canada. Alstom photo.

This is the Hydrogen Fuel Cell Trains Association’s (HFCTA) second article in a series of four addressing HFC-powered trainsets, locomotives and streetcars that are commercially available, in development, or planned around the world. HFCTA’s first article addressing these subjects was published by Railway Age in April 2022.

Why the quest for zero-emission rail transportation? Reducing harmful GHG (greenhouse gas) emissions sustains our earth to be livable for our grandchildren and generations beyond. It is not the purpose of this article to debate the issue that, over the years, combustion of fossil fuel has caused or at the very least acerated global warming This article accepts the findings of the United Nations Intergovernmental Pannal on Climate Change (IPCC) reports. Thus, application of HFC technologies complies with the reduction of harmful GHGs. Our purpose is to provide readers a synopsis of significant events that have recently occurred that are significant to our cause: replacing diesel-powered equipment with zero emission HFC-powered locomotives and passenger trainsets.

How does a fuel cell function? In brief, an HFC is composed of a membrane, cathode and anode. As hydrogen gas is passed through the membrane, an electrical current is generated between the anode and the cathode. The electrical energy is temporarily stored in a battery. Multiple HFCs are stacked together with combined electrical energy fed to the storage battery. The number of HFCs stacked is determined by the electrical energy required to perform a desired function.

A diesel-electric locomotive uses a traction alternator (electrical generator) driven by the diesel engine to power traction motors. An HFC-powered locomotive replaces the diesel engine and traction alternator with an HFC stack that provides the battery with the required electrical output for the traction motors.

As an alternative to diesel power, HFC offers no fossil fuel combustion, as the HFC process is chemical. There are no hydrocarbon emissions (particulate matter, carbon dioxide, carbon monoxide, oxides of nitrogen). The only byproducts of the HFC process are heat and water. There are fewer moving parts, thus less maintenance.

As an alternative to electrification with an overhead electrical energy source, there is no need for expensive catenary and its associated infrastructure (i.e., substations, transformers), because all HFC electrical energy is generated on board the vehicle. Eliminating catenary significantly reduces construction cost per track-mile and associated maintenance costs. A managed HFC system does require infrastructure (i.e., generation, storage, transport and dispensing), but its cost is equivalent to that of only a few track-miles of electrification.

Alstom last year concluded a successful demonstration of the first commercial service hydrogen-powered train in North America. Alstom’s Coradia iLint transported more than 10,000 passengers during more than 130 trips spanning 6,600 miles in a demonstration project in Quebec from mid-June to the end of September 2023. Using Alstom’s green hydrogen-powered train on this route helped save approximately 8,400 liters of diesel and averted 22 tons of CO2 emissions during this pilot. Alstom and its partners said they “have laid the foundation of a comprehensive, safe and efficient H2 ecosystem for the heavy transportation sector in North America, from production to refueling to operation. Alstom and its partners will use the results to chart the next steps to develop hydrogen propulsion technology and foster the adoption of green transportation in North America. We welcomed 34 commercial, governmental and regulatory delegations from all over North America looking “to witness this hydrogen-propulsion technology and capture the requirements for wider implementation across North America.

“This summer, we demonstrated that hydrogen trains can be an attractive, safe and viable alternative to diesel on non-electrified lines and that we can do it right here in North America,” said Michael Keroullé, President of Alstom in the Americas. “Alstom has clearly taken the lead in supporting rail operators and authorities in their environmental transformation, thanks to its unmatched portfolio of green solutions and its ability to bring together the best players in the industry.”

Alstom noted that only 1% of the North American rail network is electrified. “To decarbonize the rail sector in time to meet national, provincial and state-level climate goals, there must be significant investments in track electrification along with the adoption of alternative green traction solutions, including battery-powered and hydrogen-powered trains,” Alstom said. “We conducted this first-time-in-America demonstration as a proof of concept in real operating conditions for hydrogen trains, which bring multiple benefits, including no carbon emissions from the propulsion system, quieter operations, and a greater operational autonomy before refueling than battery-powered trains. There have been several takeaways from this demonstration: Hydrogen-powered trains are safe and reliable, if a robust hydrogen ecosystem is available to provide fuel. Hydrogen-powered mobility requires an agile and reliable hydrogen fuel production and distribution system. North America is taking the first steps toward building this kind of hydrogen ecosystem. Continued investment and commitment will be needed. To unlock the benefits of hydrogen-powered trains, North American decision-makers will need to adapt regulatory standards that were created before hydrogen was conceived for this purpose. As this ecosystem matures, it will create new jobs requiring new skillsets around the operation and maintenance of a hydrogen fuel network, hydrogen-powered traction systems and hydrogen fuel cells.”

Alstom is partnering with the Hydrogen Research Institute of the Université du Québec à Trois-Rivières to analyze the results of the demonstration project and will issue a final report for public authorities in early 2024. The demonstration project was made through a partnership of Alstom, which supplied and maintained the trains; Train de Charlevoix/Réseau Charlevoix, who made their teams and tracks available; Harnois Énergies, which provided the right amount of green hydrogen at the expected pressure; HTEC, which implemented the mobile hydrogen charging solution; and Accelera by Cummins, which supplied and maintained the fuel cell during the pilot. The Government of Quebec authorized and supported the project.

The Coradia iLint, the world’s first HFC passenger train, has operated more than 136,000 miles in eight European countries since it started commercial service in 2018.

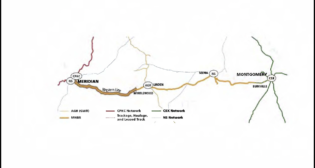

CPKC’s (Canadian Pacific Kansas City) linehaul HFC locomotive, the HSOEL (Hydrogen Zero Emissions Locomotive) will haul Teck Resources coal in 2024. CPKC and Teck will conduct a pilot program starting in early 2024 in which coal used in steel production will be transported from Teck’s mines in southeastern British Columbia. The companies have entered into a long-term rail service agreement that will run until the end of 2026. The agreement builds on existing services. In November 2021 CPKC (then Canadian Pacific) received a $15 million grant from Alberta to increase the number of HFC locomotive conversions and add hydrogen production and fueling facilities.

CPKC said it “is proud to work with organizations such as Teck that share our passion to be leaders for a sustainable future as we look to take the next step in the development of our innovative hydrogen locomotive program. The pilot will help reduce supply chain GHG.”

“The collaboration with CPKC to pioneer HFC locomotive technology supports our climate action strategy and our objective of achieving net zero by 2050,” said Teck. “The agreement complements our Neptune Terminals investment and other secured West Coast port capacity to support the efficient movement of our high-quality Canadian steelmaking coal to our global customers.”

CPKC and CSX established a joint venture for building and deployment of HFC locomotive conversion kits for diesel-electric locomotives. Initially, CSX plans to convert one of its diesel locomotives using a hydrogen conversion kit developed by CPKC. The conversion work will be done at CSX’s Huntington, W.Va. locomotive shop.

CPKC has deployed a second HFC locomotive for testing in terminal operations, a program expansion supported by funding awarded by Emissions Reduction Alberta and the Government of Canada Low Carbon Economy Fund. The second hydrogen locomotive is expected to enter service later in 2023.

During Railway Age’s Next-Generation Motive Power webinar in September 2023, Kyle Milligan, AVP Operations Technology, CPKC stated:

- 2024: the HSOEL locomotive will be pulling 152 coal loaded freight cars, 20,000-ton coal trains at 50 MPH.

- “Blue hydrogen” fuel will be supplied by Air Products.

- Operational range is increased by using a fuel tender.

- Two additional diesel-powered locomotives are being transitioned to HFC-powered: a 4,400-hp road unit and a switcher.

- CPKC has a plan to transition its entire fleet of diesel locomotives to HFC.

- Prior to 2050, CPKC’s entire motive power fleet will be zero-emission.

During the summer of 2023, the Federal Railroad Administration witnessed an operational demonstration of the HSOEL near Kansas City. FRA said it “is pleased CPKC is making efforts to improve the sustainability of its rail operations, and the agency is committed to partnering with railroads and stakeholders to advance our climate and sustainability goals. As research in hydrogen fuel cells and other emerging technologies continue, the agency will closely monitor new developments to ensure compliance with FRA regulations.”

An overview of FRA’s environmental and sustainability efforts is available on the agency’s Rail Climate Considerations webpage. In addition, in April 2022, FRA launched its Rail Industry Climate Challenge, which asks rail operators as well as manufacturers of rail equipment to commit to reaching net-zero emissions by 2050.

On Dec. 6, 2023, during the United Nations COP28 meeting, a Joint Statement by Transport Canada, the United States Department of Transportation (DOT) and the United States Department of Energy (DOE) on Taking Action to Reduce Rail Sector Emissions was issued. “Recognizing the important role transportation plays in reducing greenhouse gas emissions, the United States and Canada have created a Rail Decarbonization Task Force to develop a common vision to reduce emissions from the rail sector,” the agencies said. Together, we intend to establish a joint research agenda to test the safe integration of emerging technologies, including hydrogen-powered and battery-electric locomotives; coordinate strategies to accelerate the rail sector’s safe transition from diesel-powered locomotives to zero-emission technologies to ensure a net-zero rail sector by no later than 2050; and collaborate on the development of a U.S.-Canada rail sector net-zero climate model by 2025.

However, the DOT/DOE and Transport Canada have not identified a joint development site, and this action may not be funded until 2025.

Elsewhere, Bilton Weldon and Manufacturing has been working to convert three diesel locomotives into hydrogen-powered locomotives, with the expectation that these locomotives could enter service at the end of this year.

![“This record growth [in fiscal year 2024’s third quarter] is a direct result of our innovative logistic solutions during supply chain disruptions as shippers focus on diversifying their trade lanes,” Port NOLA President and CEO and New Orleans Public Belt (NOPB) CEO Brandy D. Christian said during a May 2 announcement (Port NOLA Photograph)](https://www.railwayage.com/wp-content/uploads/2024/05/portnola-315x168.png)