Sophisticated Simplicity

Written by William C. Vantuono, Editor-in-Chief

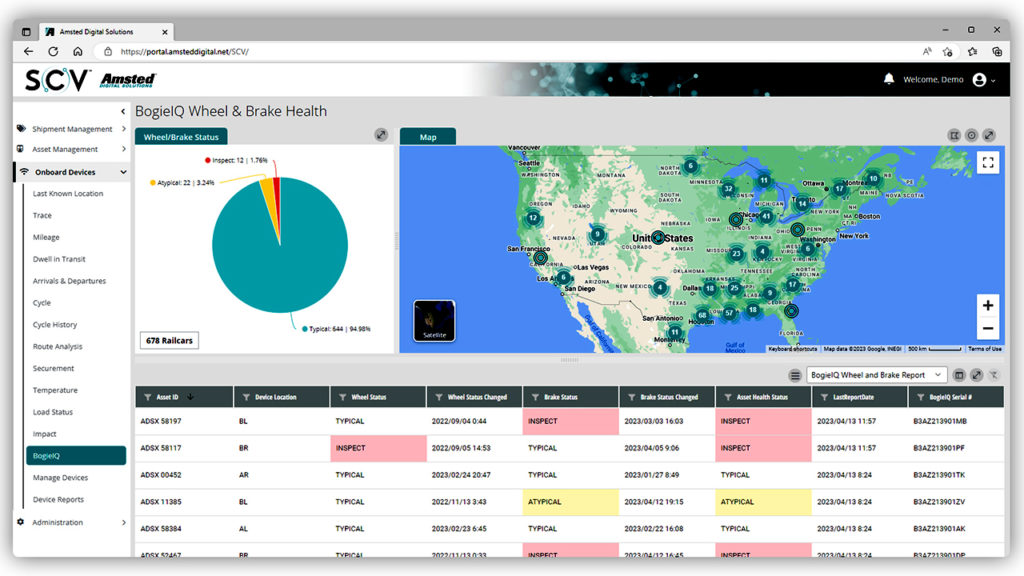

RAILWAY AGE, AUGUST 2023 ISSUE: The Amsted Digital Solutions Bogie IQ™ takes onboard health monitoring to a new level.

Described by Amsted Digital Solutions (ADS) as “a first-of-its-kind telematics system integrated directly into the bogie (three-piece truck),” Bogie IQ™ technology monitors wheelset conditions and brake system performance without wireless sensors. One device per bolster provides real-time onboard health monitoring with GPS-derived, machine learning-enhanced telematics data such as Dynamic ETA, first- and last-mile validation and “accurate mileage.” ADS’s Supply Chain Visibility™ software “provides a quick and easy means to manage by exception and review actionable information immediately.” This device, ADS notes, is “quickly and easily installed on any Amsted Rail® bogie” with specialty tools or hardware. Configuration can be done remotely. Built-in Object Character Recognition (OCR) and barcode scanning enables device association.

Bogie IQ™ has gradually evolved from concept to test to revenue service. “We started with a variant in late 2017,” says ADS Executive Vice President and COO Brad Myers. “The first application was limited to 10 railcars of varying types, one of which was a test car. They operated for about 18 months. Each car was equipped with a wireless sensor in every bearing adapter, two braking force sensors and a gateway.”

Today, the design is greatly simplified. “Our target was to take that type of sophistication down to a simple package form,” notes Myers. “We now have a single gateway mounted on the bolster on opposite sides of the car, similar to AEI tags, for directional orientation. Those devices have been in revenue service almost two years now on two car types on two different fleets. One operates between the East Coast and West Coast, the other with a utility company running out of the Powder River Basin. It has been very satisfying to see the performance so far. Fast-forward to where we are today, packaging and selling the platform.”

“We’ve signed multiple contracts in the past couple of months, both domestic and in Europe,” adds Myers. “One common misconception is that the device must be mounted underneath. It doesn’t. The IQ Series is a platform, like an iPhone, in that you can mount it on the carbody. For clients that want to monitor wheelset and brake health, if they mount the Bogie IQ™ on the bogie, we perform a configuration change over the air to the device to turn on those features and start monitoring for wheelset and brake defects. Adding a second device to the other bogie provides visibility across all four wheelsets. On the other hand, if a customer wants to install a single device on the B end of the car to primarily monitor the brakes, we can do that, too.”

One advantage of Bogie IQ™ is that it is upgradable and does not require frequent hardware changeouts. Roller bearing health monitoring capability is next. “As we add new features like acoustic bearing detection, we’ll be able to push a configuration change over the air to activate them,” says Myers. “Our customers will not have to worry about sunsetting. We’ve built a platform with a hybrid solar battery design that offers prolonged life. We’ve got a robust microprocessor with plenty of onboard memory, so as we add features, we’ve got the required processing capability and memory. Our strategy is to provide customers 7-10 years at minimum to realize a return on investment. Adding new features will involve just a simple upgrade fee. We send the configuration over the air, and off they go.”