Fortis Construction Advancing

Written by Marybeth Luczak, Executive Editor

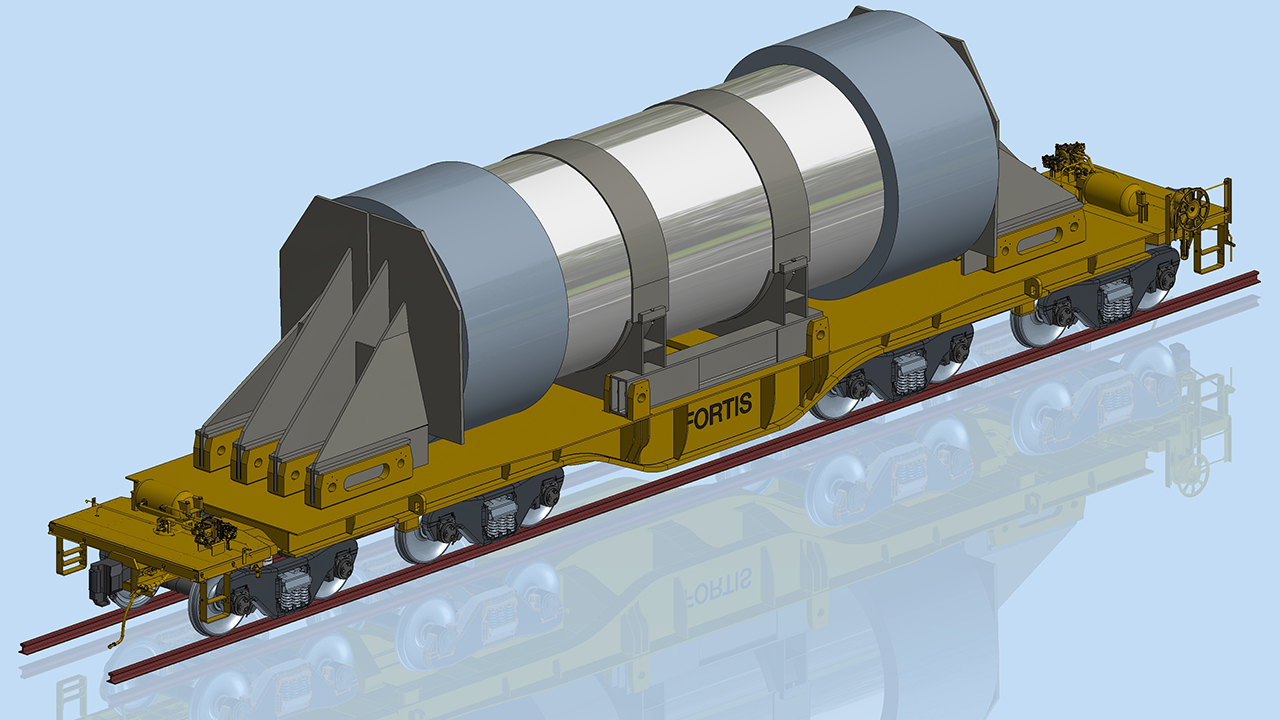

Department of Energy prototype Fortis eight-axle cask-carrying railcar design. (TTC Operated by ENSCO)

Fabrication of a new railcar to transport spent nuclear fuel and high-level radioactive waste is now under way.

The railcar, called Fortis, is being developed by the U.S. Department of Energy (DOE) and is expected to be operational before the end of the decade.

The Association of American Railroads’ (AAR) Equipment Engineering Committee in 2021 approved the design of the 8-axle flat-deck car, which will include high-tech sensors and monitoring systems, and Kasgro Rail Corp. (Kasgro) recently started producing deck components for the Fortis prototype at its New Castle, Pa.-based facility, DOE’s Office of Nuclear Energy reported March 18. Preliminary design and analysis was completed last spring.

ENSCO partnered with Kasgro for fabrication of the railcar; Oak Ridge Technologies for cask-mounting hardware; and RailcarCO Corp. for project support. The Fortis railcar project is also receiving technical and design support from Pacific Northwest National Laboratory.

Once fabrication is finished, the railcar will be transported to the Federal Railroad Administration Transportation Technology Center (TTC), which is run by ENSCO in Pueblo, Colo. There it will undergo testing according to AAR Performance Specification for Trains Used to Carry High-Level Radioactive Material (HLRM) – Standard S-2043, which is a part of the Manual of Standards and Recommended Practices – Car Construction Fundamentals and Details.

“The Fortis railcar’s move from design into fabrication and eventual testing demonstrates DOE’s commitment to safe and secure spent nuclear fuel transportation,” said Dr. Erica Bickford, DOE’s Federal Manager for the Fortis railcar project. “This is a necessary component to operationalize DOE’s integrated waste management system for storage and disposal of spent nuclear fuel.”

The DOE has also developed a 12-axle railcar, called Atlas, which wrapped up final testing in 2023.

According to the Office of Nuclear Energy, Fortis and Atlas “will provide the DOE transportation system more flexibility when transporting payloads of spent nuclear fuel and high-level radioactive waste to future federal interim storage facilities and disposal sites.”

It said that Fortis will incorporate the same cargo attachment system as Atlas and will have the same integrated security and safety monitoring system.

Fortis, however, will be shorter in overall length than Atlas and used to ship smaller and lighter packages, or to load casks of spent nuclear fuel at nuclear power plants that may be space-constrained, the Office reported.

On average, DOE anticipates shipping about five casks of spent nuclear fuel on a train at one time, with each railcar hauling one cask. According to the Office of Nuclear Energy, DOE intends to eventually transport more than 140,000 metric tons of commercial spent nuclear fuel that is estimated to be generated in the U.S. by 2060; transport is expected to occur over many decades.

DOE is now “pursuing a consent-based process to site one or more federal consolidated interim storage facilities for spent nuclear fuel to fulfill its responsibility to take ownership of this material and eventually dispose of it,” the Office of Nuclear Fuel reported.

Further Reading:

Fortis Prototype Fabrication and Testing