Watch: BNSF Implementing Virtual Reality Training

Written by Marybeth Luczak, Executive Editor

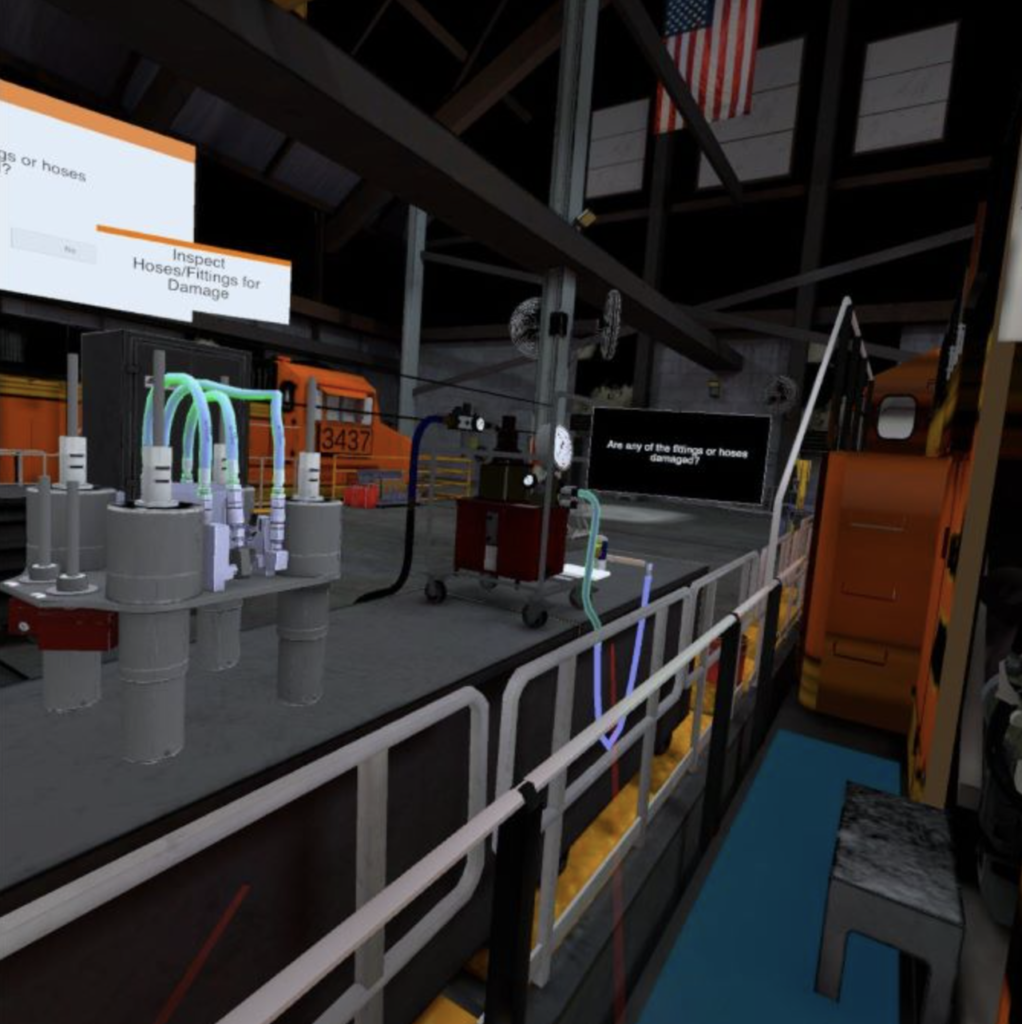

Pictured: A BNSF student using virtual reality to learn how to adjust the gear lash on a high-pressure fuel pump. (Screen Grab from BNSF video)

BNSF is including immersive technology in its mechanical training programs to help keep workers safe and improve role readiness, the Class I reported March 29.

With the help of Virtual Reality (VR) learning solutions provider Roundtable Learning, BNSF said it is testing training simulations “to address risk-specific scenarios to potentially avoid incidents and injuries while on the job.”

VR training complements existing instructor-led mechanical programs, “by reinforcing learning techniques that cannot be replicated in traditional training modalities,” according to the railroad. Built for “in-depth exposure to step-by-step processes,” the VR training allows mechanical employees “to build their knowledge of the importance of personal protection equipment (PPE), improve risk awareness, and hone seamless lock-out tag-out procedures,” the railroad said. “Each time employees encounter safety hazards within the VR experience, warnings alert learners to pressurized systems and reinforce safe lifting practices,” for example.

“We continue to invest in new technologies like virtual reality simulations to enhance our mechanical training programs even more,” said Mark Stockman, BNSF Director of Mechanical Training. “They serve as an integral tool in bridging frontline work with digital technology and prioritizing our vision of a workplace free of accidents and injuries.”

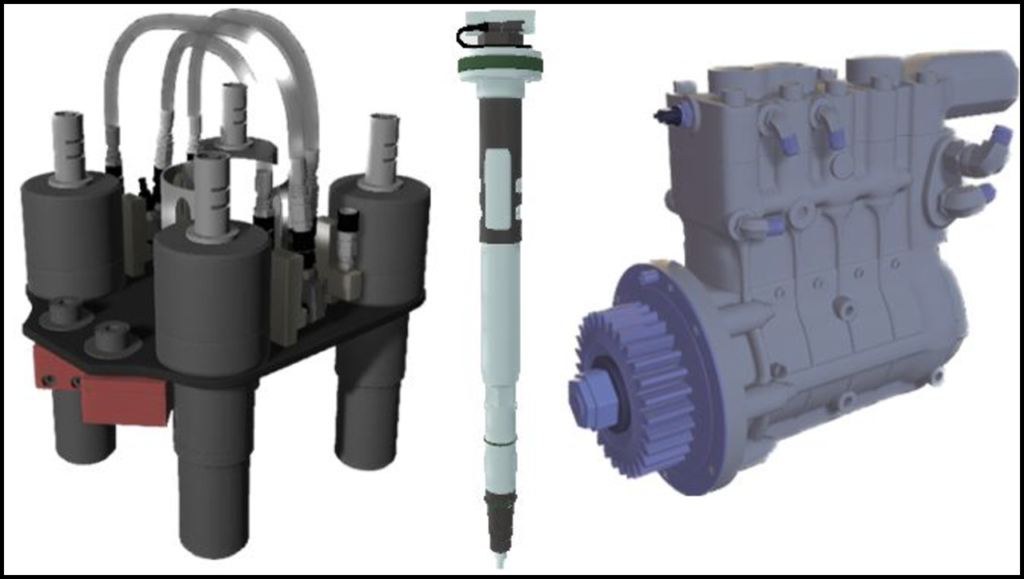

After more than two years, BNSF has eight VR mechanical training modules, all covering maintenance processes for Tier IV locomotives. These modules include three safety briefings, fuel pump installation and removal, injector installation and removal, and specialty tooling tension/de-tension processes, according to the railroad.

How Does VR Training Work?

BNSF provided the following example (scroll down for a video demonstration):

“You’re handed a headset and told to stand within a square marked off on the floor with tape” BNSF explains in an example. After lowering the headset over your eyes, you’re no longer in the training room. You’re in a BNSF mechanical shop, standing on the walkway of an orange locomotive.

“A friendly BNSF employee stands in front of you. She greets you and walks you through a detailed training program. Before you know it, you’re reaching out and grabbing digitally generated tools, reading instructions that are hovering in front of you, following a complex procedure to change out parts inside the engine.”

The experience of working in a virtual environment may be disorienting at first, and it takes practice grasping and manipulating the 3D-rendered tools and parts, according to BNSF, but the railroad noted that “most employees adapt well to the new training.”

“We have had very few cases where folks just don’t grasp it,” said BNSF Locomotive Mechanical Manager Christopher Skinner, who has played a leading role in the implementation of VR training and serves as a liaison between the railroad and project vendor. “There is a desktop version employees can use if they don’t take to the virtual environment.”

How Was the Technology Deployed?

Deploying the technology at BNSF was a massive undertaking because of the volume of information that had to be compiled to build the mechanical training courses digitally, according to Skinner.

This included rendering many objects in 3D. “We had to build models and make sure they looked accurate and had the level of detail that we needed—anything from the locomotive to the shop environment to individual components and tooling,” Skinner said.

In many cases, where a digital equivalent of a tool or part didn’t exist, BNSF Technical Training Center employees had to make one, according to BNSF. “We really had to kind of reverse-engineer the locomotive to build the components that we needed,” Skinner explained. “We’d obtain the physical component and take multiple photos from different angles, with a tape measure or ruler for perspective.” With that information, the digital component was created.

“Sometimes we’d get permission from a mechanical shop to disassemble parts of a non-production locomotive to take photos and measurements, and we’d also take videos of the process,” Skinner said. “So instead of trying to explain to the vendor what the exact process was, the video could show the process we’re trying to replicate.”

According to BNSF, much of the digital-parts modeling work was performed by Senior Specialist for Railroad Training Bill Snyder, who sees the advantages of digital training.

“Kids coming up nowadays love their video games, and people learn very easily with video games,” Snyder said. “I would love to have our training set up where you can just give it to the students and let them go in and explore the environment. I want to have a training environment that engages our students and makes them want to be in it, so when you tell the student they’ve got five more minutes to finish, they’re asking for five more minutes or another half hour because they don’t want to stop.”

Looking Ahead

According to Christopher Skinner, BNSF has implemented mechanical VR training in the field and “the plan is to have folks who attend our Tier IV instructor-led training class go through the VR material first before they perform the process in reality.”

That’s important for safety, BNSF pointed out. “You can literally practice these processes dozens of times inside this virtual reality environment until you’re familiar and comfortable with them,” Skinner said. “And then you can go and safely implement them in real life.”

Additionally, Skinner sees the potential for continued investment in the technology, including acquiring more headsets to be permanently available at multiple work locations around the network, according to BNSF.

“We’re also looking at adding haptic gloves,” Skinner said. “You get real-life resistance to your hands to make it feel like you’re picking up items, which adds to the realism of the training.”

According to BNSF, the range of coursework available will potentially expand over time. “The dream is that we have a large library spanning across various departments and crafts,” Skinner said.

“Safety, efficiency, consistency, and immediate availability of training, regardless of location: The training might be virtual, but the benefits are very real,” BNSF summed up.