New From Shift5: Predictive Maintenance Module

Written by William C. Vantuono, Editor-in-Chief

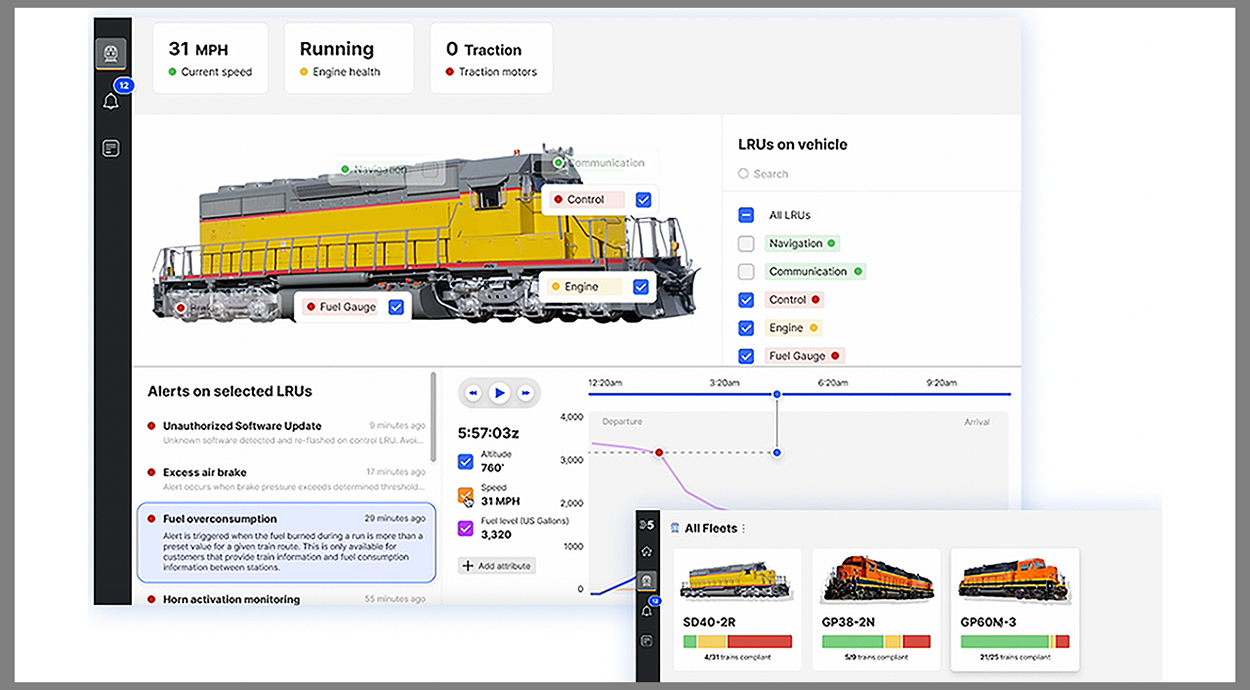

Shift5, best known for its cybersecurity capabilities in the rail, aviation and defense sectors, has expanded its offerings with a Predictive Maintenance Module that “enables smarter, faster maintenance decisions and actions through real-time data access, contextual insights and actionable analytics.”

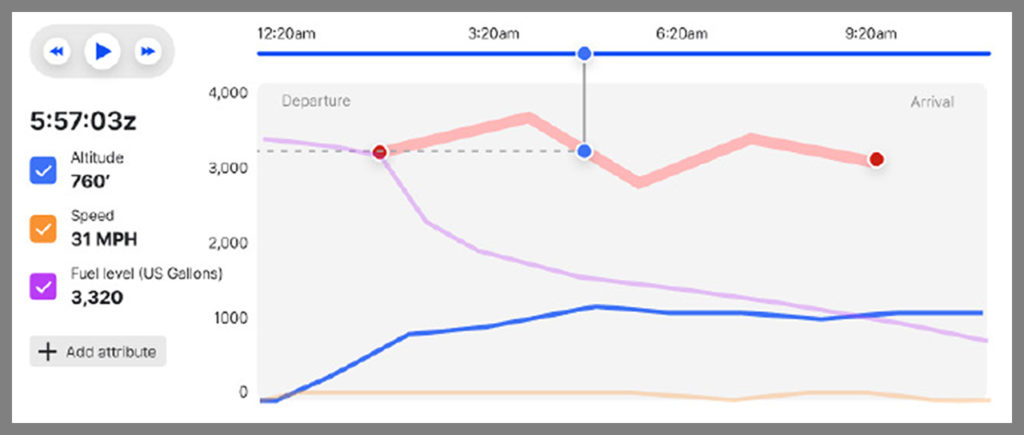

The Shift5 Predictive Maintenance Module “leverages the Shift5 platform’s real-time access and analysis of onboard data to deliver actionable insights needed to predict and schedule maintenance effectively,” the company says. “This proactive approach to maintenance helps teams stay ahead of critical failures and support the safety and performance of transportation and defense assets,” rail rolling stock of all types (locomotives, multiple-units, passenger cars, etc.) among them.

“Optimizing the performance and availability of existing legacy assets and newer, technologically advanced ones is an increasingly complex and costly challenge,” Shift5 notes. ”The components and data busses onboard locomotives generate enormous volumes of data that can enable faster, more precise maintenance outcomes, but existing solutions can’t capture or analyze this valuable data. With complete observability of all onboard data, owners, operators and maintainers get the insights and context they need to make real-time decisions that help improve the safety and reliability of their most critical, expensive and long-lasting assets. Our unique platform is hardware-, buss- and protocol-agnostic and can perform passive, full-take data capture from components and data busses onboard locomotives—every frame, every bus, every protocol. It can analyze data in real-time to provide operators and maintainers with insights to assist in predicting and scheduling maintenance effectively, helping avoid critical failures before they happen.”

For example, diesel-electric locomotives are typically equipped with seven to nine serial data busses. Among them are RS-232, RS-485 and J-1939, Multifunction Vehicle BUS, Ethernet Train Network and Ethernet TCP modules that interface with various LRUs and ECUs (microprocessor engine controls, electrical gear, PTC and communications equipment, braking and other systems and subsystems) The Predictive Maintenance Module “vacuums” data from these sources into an Onboard Analytics Translation Module that transforms raw data into a human-readable format proving Deterministic and Non-Deterministic Anomaly Detection and Deep Enrichment. An On-Platform Loader provides alerts that go to off-vehicle maintenance and SOC (security operations center) analysts and scalable storage.

Shift5 notes that readiness and reliability of such systems “are critical.” According to results from a survey of operators and maintainers in the rail, aviation and defense sectors conducted by Shift5 and MeriTalk, “66% experienced preventable fleet downtime due to a lack of effective predictive maintenance. Furthermore, 77% agreed that their organization’s current tooling failed to provide the access and visibility needed for effective predictive maintenance. Nearly 75%) agreed that better maintenance decisions are only possible with access and visualization of real-time onboard data, the most important capability of predictive maintenance.”

The Shift5 Predictive Maintenance Module “complements existing toolsets by collecting and analyzing the enormous volumes of onboard data generated across entire fleets,” the company says. “It transforms raw data into human-readable, context-rich actionable insights, enabling teams to detect, identify, alert and take action on operational anomalies. This proactive detection can help teams achieve faster, more precise maintenance outcomes at scale. By providing complete observability of onboard data, it empowers teams with the insights and context needed to make real-time decisions that can enhance the safety and reliability of their fleets.”

In addition to its predictive maintenance capabilities, Shift5 says the Predictive Maintenance Module “can democratize data and analysis by integrating with customers’ existing systems, toolin, and storage, further enhancing team effectiveness and efficiency. The Module provides four key benefits for operators:

- “Observability: access, translate, and store onboard operational data, which can be used to monitor asset performance for patterns or trends that could indicate problems or maintenance issues.

- “Readiness: make better, faster decisions by scheduling maintenance at optimal intervals to reduce downtime, improve availability, optimize resource use, and automate early warning indications to mitigate problems before they cause delays.

- “Safety: automate monitoring of system thresholds to forecast and predict equipment failure, perform scheduled maintenance to help reduce the risk of malfunction, and identify and prioritize potential safety hazards.

- “Cost savings: help ensure assets remain in service longer to prevent costly delays and lost revenue, identify and prioritize potential safety hazards to aid in mitigating legal liabilities and fines, and keeping assets and components at optimal performance levels to extend their life.”

“Defense, aviation, and rail maintenance and operations teams have demanding jobs compounded by high stakes,” comments Shift5 Chief Technology Officer Egon Rinderer. “Downtime impacts the flow of goods, can ground commercial aircraft and reduces Department of Defense fleet readiness. Traditional maintenance capabilities are reactive and inefficient. Our Predictive Maintenance Module flips the paradigm and allows teams to use real-time data to shift to a proactive, preventative maintenance stance. It enables comprehensive capabilities that improve fleet readiness and the cost to operate and maintain those assets. We bring value by driving down costs while increasing uptime, a major bottom-line goal of any organization in the transportation industry.”