Force Control

RAILWAY AGE, FEBRUARY 2024 ISSUE: Nearly 140 years after the first patent was issued, draft gears and cushioning devices remain as fundamental to railroading as steel wheels rolling on steel rails. Few

RAILWAY AGE, FEBRUARY 2024 ISSUE: Nearly 140 years after the first patent was issued, draft gears and cushioning devices remain as fundamental to railroading as steel wheels rolling on steel rails. Few

Railcar component manufacturer Miner Enterprises, Inc. on Nov. 28 has announced that Paul Aspengren has been promoted to Director of Sales, effective immediately.

RAILWAY AGE, NOVEMBER 2023 ISSUE: High-production, computer-driven track machines and inspection vehicles perform one of the most critical of maintenance-of-way functions: keeping ballast in a state-of-good-repair to provide a smooth-running surface with excellent drainage.

Railcar component manufacturer Miner Enterprises, Inc. on Oct. 20 announced that John Swezey has been appointed as the company’s President and General Manager, effective Nov. 1.

Miner Enterprises, Inc. hires Ross Hartley as International Sales Manager. Also, the Port Authority of New York and New Jersey (PANYNJ) announces Amy Fisher as General Counsel overseeing the agency’s law department.

Miner Enterprises, Inc., has earned the Supplier Evaluation Committee Award (SECO) from TTX Company for the 27th consecutive year, achieving Supplier Excellence status each year since the program’s inception.

David Withall, Chief Executive Officer of Miner Enterprises, Inc. for 24 years and a 53-year company veteran, has died after a brief illness. He was 78.

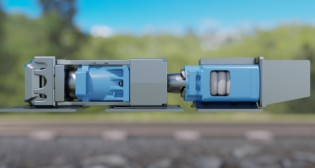

RAILWAY AGE, MARCH 2023 ISSUE: Critical components like couplers, draft gears and end-of-car cushioning units must be capable of managing thousands of tons of force.

RAILWAY AGE NOVEMBER 2022 ISSUE: High-production machines and attachments, as well as computerized inspection vehicles, are built by (and sometimes operated under) multiple suppliers to help dump, spread, tamp, profile and clean ballast, helping to keep track in its place.

Miner Enterprises, Inc. reports that it has received orders for more than 1,000 carsets of its Miner Friction Cushioning System (Miner FCS) end-of-car-cushioning (EOCC) devices, adding to the 2,700 carsets already in service. The new orders, expected to be shipped during the next few months, are from Class I railroads and car lessors for boxcars and coil-steel gondolas.