TSB: Railcar Structural Failure Led to 2019 CN Tunnel Derailment

Written by Marybeth Luczak, Executive Editor

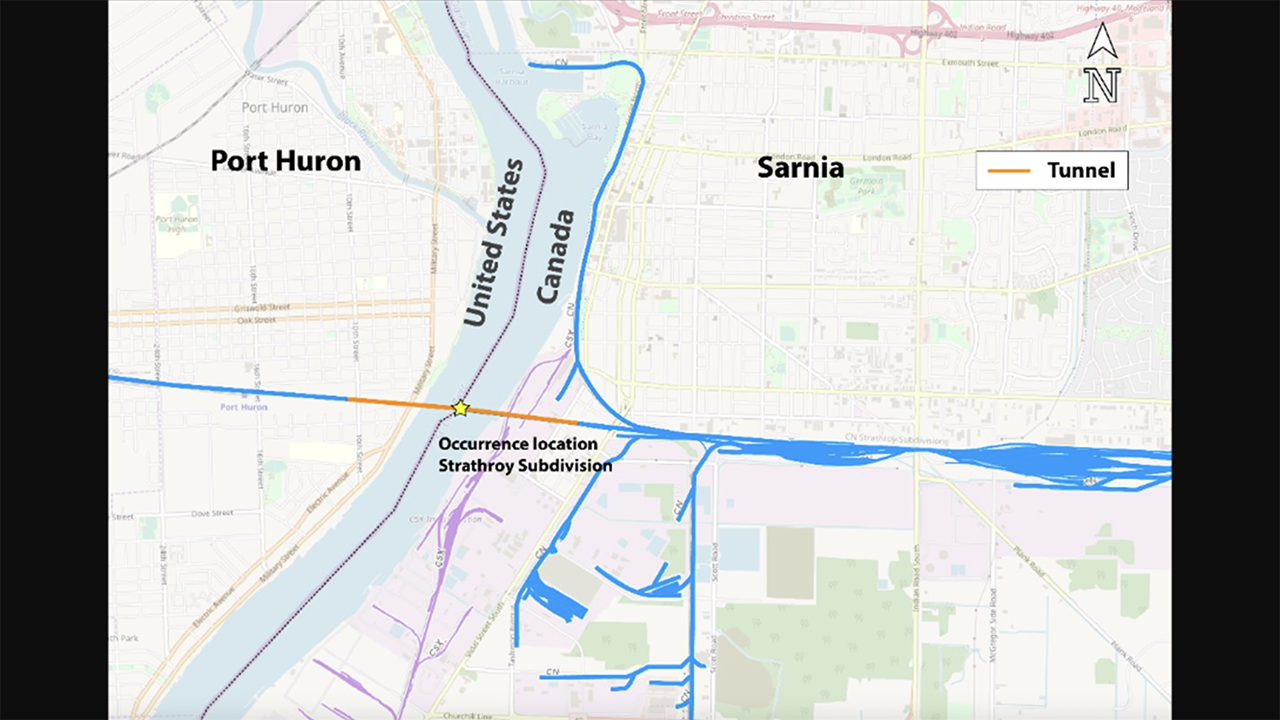

Map showing the June 28, 2019, route of CN train M38331-27 the derailment location. (Source: Railway Association of Canada, Canadian Rail Atlas, with TSB annotations)

The Transportation Safety Board of Canada (TSB) on Dec. 18 reported that structural failure of a bathtub gondola car led to the 2019 derailment of a CN train proceeding through the CN Paul M. Tellier Tunnel en route from Sarnia, Ontario, to Port Huron, Mich. At the time of the accident, “there was no industry or regulatory requirement to periodically conduct a full inspection of the car to ensure it maintained its structural integrity,” the TSB reported. “As a result, its structural integrity deteriorated and this was not identified. ...”

A train-initiated emergency brake application occurred while train M38331-27—comprising two head-end locomotives, one mid-train distributed power remote locomotive, and 140 freight cars—was traveling at 44 mph in the 6,130-foot-long tunnel on June 28, 2019, TSB reported in its newly released investigation report (download below). The separated head-end portion of the train stopped outside the tunnel at Mile 61.46, while the tail-end portion stopped outside the tunnel’s east portal in Sarnia (see map, top). A total of 45 cars, including one tank car that released 12,000 gallons of sulphuric acid, and the distributed power remote unit derailed and came to rest on both sides of the international border inside the tunnel; no injuries were reported.

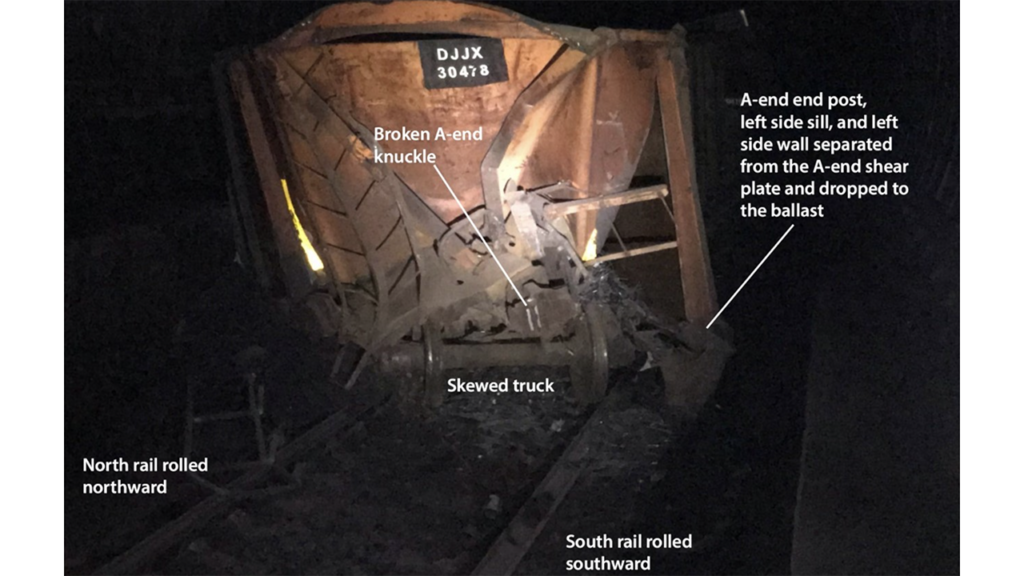

The TSB said its investigation determined that the accident occurred when bathtub gondola car DJJX 30478, loaded with scrap steel, “sustained a structural failure and the A-end left side of the car collapsed, causing the car to derail in the tunnel on the Canadian side of the border. As car DJJX 30478 collapsed, the A-end truck became skewed beneath the car, causing both rails to roll outward and derail the trailing cars.” According to the TSB, “structural defects that were present in the shear plates, stub sills, car body bolsters, and side sills, as well as thinned out steel sections due to corrosion of car DJJX 30478, negatively affected the ability of the car to withstand in-train forces.”

The car was built in 1978 by Berwick Forge & Fabricating Corporation (Berwick Forge), and modified in 2012 for use in scrap steel service, the TSB reported. According to the agency, “visual examination determined that the defects were not recent but had developed over a period of time.” It noted that “[d]espite its deteriorated condition, the car traveled frequently within, and between, Canada and the U.S. and was interchanged between railways 16 times in the six months preceding the accident. In the three months prior to the accident, it received 24 certified car inspections and had numerous pull-by inspections, with no significant structural defects noted.”

Neither the Canadian freight car safety rules, the U.S. freight car safety standards, nor the Association of American Railroads (AAR) Interchange Rules “contained limits to identify defects to certain structural components of freight cars, such as those present in the failed gondola car,” the TSB reported. “Thus, the structural defects did not prevent the car from remaining in service.”

Following the derailment, the TSB issued four rail safety advisory letters (RSAs):

- RSA 08/19 (Aug. 19, 2019) advised Transport Canada “to ensure that railways have specific instructions or guidance in their emergency procedures for conducting train inspections following a derailment in a tunnel involving dangerous goods.”

- RSA 09/19 (Sept. 16, 2019) advised Transport Canada and the U.S. Federal Railroad Administration (FRA) “to ensure that railways and car owners have procedures in place to identify, inspect, and repair (as required) bathtub gondola cars that are equipped with stub sills, particularly those being used in scrap iron and steel service, which were constructed in the late 1970s and early 1980s.”

- RSA 06/20 (Sept. 11, 2020) advised Transport Canada “to ensure that all railways have adequate practices in place to effectively manage in-train forces.”

- RSA 07/20 (Sept. 11, 2020) advised Transport Canada and the FRA “to ensure that all bathtub gondola cars built by Berwick Forge and that operate in North America, are identified, located, and examined to ensure continued safe railway operations.”

In response to RSA 08/19, CN informed the TSB that it installed “permanent visual and audible alarms in the tunnel’s portals, which will alert employees to the presence of toxic gases,” according to the agency, which noted that the Canadian Class I railroad also issued to its employees a summary bulletin, including new emergency procedures that must be followed by crew members in the event of an emergency in a tunnel.

Additionally, CN inspected 416 of the 2,130 identified cars of similar type and vintage to the bathtub gondola car that failed in the tunnel and that were being used in scrap iron and steel service in North America, identifying defects in 149 of the 416 cars (36%), according to the TSB.

In response to RSA 08/19, Transport Canada wrote to the Railway Association of Canada and the Western Canadian Short Line Railway Association “recommending that Canadian railways ensure that their equipment, procedures, and instructions be reviewed and updated, as required, to ensure employee safety,” the TSB reported.

Also, in response to RSA 09/19 and RSA 07/20, Transport Canada contacted the AAR and continued to follow up with the AAR “to ensure that all of the cars identified in the AAR-issued Maintenance Advisory MA-0188 were inspected,” according to the TSB, which noted that the 2020 AAR Interchange Rules were revised to include defect limits for additional freight car structural components.

The AAR issued maintenance advisories MA-0188 and MA-0198, Early Warning EW-5344 and Equipment Instruction El-0017 to the rail industry “requiring the inspection of specified bathtub gondola cars,” according to the TSB. “Equipment Instruction El‑0017, which was issued subsequent to the maintenance advisories and early warning, requires Berwick Forge bathtub gondola cars of the same vintage as the occurrence car to be inspected every two years. Cars identified in the equipment instruction are automatically prohibited from interchange under the AAR Interchange Rules unless they have been inspected within the two-year timeframe and determined to be free from specified defects. The process will repeat every two years for each car on the list.”

The TSB added that the 2020 AAR Interchange Rules governing center sills, draft sills, coupler carriers, and side sills were revised to include “causes for attention related to stub sills and side sills defects.”

![“This record growth [in fiscal year 2024’s third quarter] is a direct result of our innovative logistic solutions during supply chain disruptions as shippers focus on diversifying their trade lanes,” Port NOLA President and CEO and New Orleans Public Belt (NOPB) CEO Brandy D. Christian said during a May 2 announcement (Port NOLA Photograph)](https://www.railwayage.com/wp-content/uploads/2024/05/portnola-315x168.png)