Sealing tank car manways to prevent NARs

Written by Wayne Evans, Product Engineer and IP Lead, Garlock Sealing TechnologiesBoth the rail industry and U.S. Government are seeking to reduce the volume and severity of leaks from railcars. The Association of American Railroads (AAR) began tracking non-accident releases (NARs) in 2001, gathering data on the impact of sealing on industry performance and safety.

Of the more than 14 seals on a typical railcar, particular attention needs to be given to tank car manway systems, which are responsible for more than 60% of such releases in general service cars, according to the AAR. Understanding and reducing NARs in the rail industry is an important goal for both the industry and general public.

General service cars transport fluids such as crude oil, styrene, biofuels, fuel oil, sodium hydroxide and others. These cars represent more than a quarter of the U.S. and Canadian fleets (AAR 2014 data), and are the primary source of NARs in North America. 15 years of tracking NARs has identified the primary cause of NARs in this fleet–the manway. Further investigation has revealed that loose fasteners and gasket deterioration were responsible for 74% of all documented leaks.

This data points to the conclusion that the most effective way to decrease NARs in a fleet is to focus on the manway first. The need for proper gasket selection and installation is a critical part to an effective manway seal. Maximizing operational uptime, minimizing maintenance and improving safety call for effectively sealing manways. Success is subject to a number of variables, including the gasket material itself—typically rubber, PTFE (polytetrafluoroethylene) or fiber-based sheet—loading conditions, installation methods and mechanical integrity of the system (specifically the nut-and-bolt assemblies) and sealing surfaces.

Manway systems

Manway systems

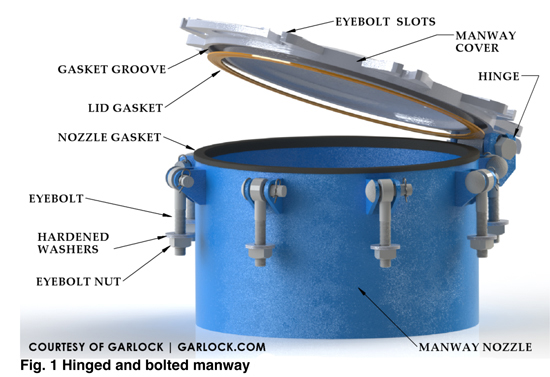

Hinged and bolted manway assemblies are usually sealed with gasket and six to eight swing bolts (Figure 1). The two common gasket styles are the lid gasket and the nozzle gasket. Typically, nozzle gaskets are rubber-based, while lid gaskets can be rubber, fiber, or PTFE-based gaskets. Note that one type of gasket is used at a time.

A visible leak rate test is often performed before a car is placed into service. These tests are typically conducted at an internal pressure of 30 or 50 psig (pounds per square inch gage, indicating that the pressure is relative to atmospheric pressure) with a leak detection fluid applied to the outside of the sealing area. If a leak is not detected or deemed acceptable, the car is dispatched into the field. All systems leak; the issue is whether the system meets an acceptable leak rate.

Bolt load recommendations are made based on gasket size assumptions from AAR manuals, specifically the nozzle sealing surface, and the torque load from the nut/bolt assembly being converted to gasket load. It should be noted that corrosion and damaged components are common, given the operational duty cycles and long service lives of these railcars. Carbon steel components are particularly susceptible to corrosion, posing an issue if sliding motion is a functional requirement.

As of 2015, the average age of the 312,581 tank cars in the U.S. was 15.4 years (AAR data), indicating the increased likelihood that corrosion has impacted the entire fleet in some manner. Commonly, this corrosion impacts the gasket through damaged sealing surfaces and/or corroded fasteners. Therefore, inspection and replacement of nut/bolt assemblies should be considered each time a manway is opened. Swing bolts with damaged threads should be replaced if the nuts will not travel under reasonable applied torque. Bolt lubrication is recommended for this application.

Yet another problem is reduced gasket loading due to damaged washers impeding the rotation of the fastener. The bolt torque goes to overcoming friction, rather than to creating force in the bolt. Physical deformation or “cupping” of these washers can prevent bolt torque from being fully converted into compressive force on the gaskets. This has the effect of reducing applied torque and gasket stress, potentially resulting in NARs (Figure 2).

Cheater bars and impact guns are common tools that can easily hide a system in poor condition. The mechanical advantage these tools provide are useful for ergonomics, but can easily mean a system is over-torqued or a damaged fastener is not noticed. This can lead to gasket stress far too high for the installed product, and cause a leak. This over-torque can also bend the manway lid, causing future issues with the gasket and bolting system.

At a minimum, hardened washers should be used. However good practice calls for the use of two hardened washers. Testing conducted by Electric Power Research Institute (EPRI) shows this can increase average bolt load by 11%, and reduce average scatter by 20% compared with a single washer. Provided the nut-and-bolt assemblies are in good working order and the proper gaskets have been selected, most manways will pass visible leak tests and return to service.

Miscommunication of gasket sizes and variability of the physical surface the gasket rests on regularly results in products being used outside their recommended loading conditions. For example, a highly beveled nozzle (vs. a nozzle face that is machined flat) will have a significantly reduced contact surface. This means the same bolt load is distributed over a smaller surface area, leading to an increase in gasket stress. Similarly, miscommunication on gasket size and contact area can result in incorrect torque calculations, leading to significant installation errors. In both these and similar cases, the result is a gasket performing at stresses far less or far greater than intended. Often the higher torque values used to seal hard gaskets are applied to soft rubber gaskets. This creates compressive stresses far greater than what the soft gasket can accommodate, causing it to crush and split, dropping half a gasket into the tank and leaving a manway susceptible to a NAR.

In order to perform in-house tests on railcar products, a fixture was built from a standard AAR-1 hinged and bolted manway from a U.S. manufacturer (Figure 3). The beveled nozzle was examined to determine the tolerances of similar nozzles. The width of the sealing surface on this 20-inch nozzle, measured at 3-inch intervals around its circumference, varied from a minimum of 0.169-inch to a maximum of 0.320-inch (Figure 4, just below Figure 3).

These measurements were used as the extremes for gasket contact area under the same bolt load and displayed in Table 1. Lower gasket stresses, typically 1,200 psi and lower, are a good range for rubber. Higher stresses are better for hard gaskets such as filled PTFE, fiber sheet or products with built-in compression stops.

For Case #1, the full width of the gasket (rather than the actual flange dimension) was communicated as the sealing contact area. When applying a typical load of 200 foot-pounds on eight bolts, about 1,831 psi of gasket stress is predicted. However, the actual stress is far higher and may cut through the gasket, since rubber and some PTFE gaskets cannot handle 23,000 psi compressive stress. Only a few gasket types will handle stress above 15,000 psi.

In Case #4, a highly chamfered edge on the nozzle resulted in an actual gasket stress of 22,957 psi, which would likely crush or split the gasket and resulting in a NAR, regardless of the type of gasket used.

These scenarios highlight the critical importance of gasket selection and loading. To avoid under- and over-compressing manway gaskets, confirm that bolt loads align with both the gasket material and size. Determine the proper torque based on actual contact dimensions, not the gasket I.D and O.D. Calibrated torque or tension equipment is recommended to ensure gaskets are properly loaded.

A few simple checks are also useful. If a soft rubber gasket is being split, consider a harder (fiber or PTFE) gasket, which is more crush resistant.

Figure 5 shows a common rubber nozzle gasket: If split, the inner ring of rubber is no longer supported and falls directly into the railcar. If there is not a uniform indentation on the used gasket, consider inspecting and replacing the swing bolts. Loose washers, after a system has been tightened, indicate a damaged fastener. Best-practice recommendations include lubricated bolts and two washers on each nut to prevent “cupping” and improve force transfer.

Gasket selection and installation

Rubber gaskets are commonly used in general service cars, being the easiest for effectively sealing manways. However, they are limited with regard to temperature and chemical compatibility. PTFE gaskets are growing in popularity due to their nearly universal chemical compatibility. Depending on how they are processed and the type of fillers used, these gaskets can range from hard to soft. Calendered PTFE gaskets are typically more expensive than those made of skived material, but have better, more consistent properties.

The correct stresses for effective sealing vary widely among hard PTFE, fiber-based and soft rubber gaskets. Rubber gaskets typically seal at 1,200 psi, whereas hard gaskets seal at between 2,000 psi and 10,000 psi. Applying the wrong load, a common error, will adversely affect performance regardless of the type of gasket or manufacturer. Loading a gasket by tightening the bolts in multiple passes maintains even compression, preventing it from being crushed on side and under-loaded on the other.

The objective is to match the gasket to system conditions with technical support from the sealing supplier if necessary. As noted, the performance of any gasket will be compromised by corrosion, damage and missing components. Maintaining the quality of sealing systems with periodic inspections and replacement of worn and damaged items mean fewer NARs and faster, more effective responses when they occur.

Citations:

Guidelines for Hinged and Bolted Manway Assembly, Renewable Fuels Association.

Performance Characterization of Bolt Torquing Techniques: Sealing Technology and Plant Leakage Reduction Series. EPRI (Electric Power Research Institute), March 26, 2002.

http://www.epri.com/abstracts/Pages/ProductAbstract.aspx?ProductId=000000000001003150

Tank Car NAR Data Breakdowns for the 12 Months Ending June 2014, AAR: http://www.aar.org/Documents/NAR/nar-data.pdf