BNSF Testing Kawasaki’s LATGMS

Written by Marybeth Luczak, Executive Editor

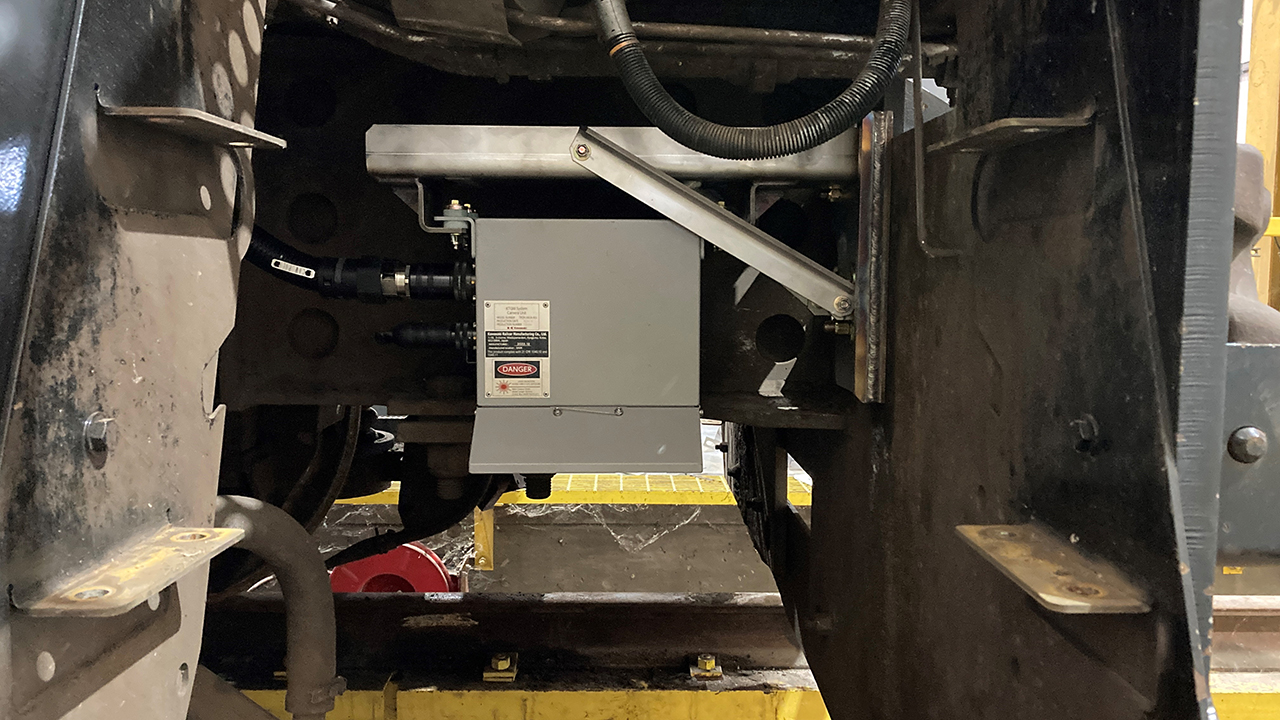

Pictured: Kawasaki Track Technologies’ locomotive-mounted autonomous track geometry monitoring system. (Photograph Courtesy of Kawasaki)

BNSF testing is under way of a locomotive-mounted autonomous track geometry monitoring system (LATGMS) from Kawasaki Track Technologies, the supplier reports.

“This technology utilizing sensors and cameras provides near real-time track geometry data for BNSF to utilize for track maintenance planning,” says Kawasaki, which notes that any time the LATGMS-equipped locomotive is hauling freight, it is testing track, “providing a frequent, valuable, and cost-efficient service to BNSF.”

LATGMS can be mounted to a locomotive or passenger railcar to continuously measure and analyze track gauge, profile, alignment, cross level and twist during normal service operations, according to Kawasaki. If a track irregularity is detected, the company says, a notification is sent to the railroad. All collected data can be transmitted in near real time to a user database or to a proprietary software suite offered by Kawasaki Track Technologies.

“Collecting data during normal service operations may decrease the frequency of inspections by dedicated track inspection cars and visual inspections by inspectors,” Kawasaki notes.

Kawasaki began testing LATGMS in 2018 and deploying production units in 2021. The company says that units now in service have provided railroads with more than 500,000 miles of geometry data.