Crew Call: Juniata Locomotive Shop

Written by Norfolk Southern Corporate Communications DepartmentOur Juniata Locomotive Shop in Altoona, Pennsylvania, comprises one of the largest facilities for locomotive repair in the industry.

Today, the shop complex is situated across 70 acres, with approximately 30 acres under roof. The dedicated team at Juniata is responsible for supporting the quality and longevity of Norfolk Southern’s locomotive fleet.

Approximately 430 of our railroaders work at Juniata. They are represented by seven crafts, including Machinists, Electricians, Sheetmetal Workers, Boilermakers, Carmen, Firemen & Oilers, and Clerks. There is strong railroad pride and sense of tradition at Juniata. Many members of the workforce have generations of extended family who are railroaders, making the facility a unique place to work.

Together, our teams perform comprehensive repairs to locomotives, including rebuilding components such as traction motors, alternators, power assemblies, and engines. For locomotive capital rebuild programs, the crew strips a locomotive to its bare frame to completely rebuild it, including the engine, alternator, wiring, cab, trucks, combos, and running gear.

They also undertake scheduled engine and truck overhauls, along with other major repairs to locomotives. In 2023, the team is scheduled to complete 88 engine overhauls, 36 truck overhauls, and to assist with capital programs that involve life extensions and DC to AC conversions.

Meet five of our railroaders at Juniata, who help keep our trains moving every day and enable us to serve our customers:

Ryan Cameron

Paint Shop Gang Leader

At Norfolk Southern since 2006

What do you do in a typical day?

I start each day off by conducting a safety meeting and then assign jobs out to the team. I take care of many behind the scenes needs to make the paint shop run smoothly. I also help sand and paint.

How does your work support our customers?

What I do maintains the integrity of our locomotives. Ensuring they have a fresh coat of paint prevents them from corroding and keeps them moving freight. Locomotives are the face of Norfolk Southern, and our team keeps them looking good.

Safety tip on the job?

Keep safety at the top of your mind and be your sister and brother’s keeper.

Bill Erndl

Machinist

At Norfolk Southern since 2005

What do you do in a typical day?

I’m on the team that rebuilds the AC traction motors and reassembles them to get electronically tested. From there, they go to the next step in the production process. I also serve on our local safety and service committee, where we address a variety of issues. I’ve worked in a variety of departments here at the facility. We really have a great team of people.

How does your work support our customers?

Our team supplies the entire system with wheel sets and traction motors. These are key components to making the locomotive run. Each locomotive has six traction motors to keep them running.

Safety tip on the job?

Stay focused in the shop because we always have things moving. Be aware of your surroundings.

Brian Hoover

Electrician Working Gang Leader

Alternator Gang

At Norfolk Southern since 1991

What do you do in a typical day?

At the beginning of each workday, I start by doing a turnover with my supervisor. He lets me know what alternators have been requested and which should be lined up for the day. I hold the daily safety meeting at 7 a.m. and then I let all members of the alternator gang know what their job assignments are for the day. I also make sure everyone has the proper tools and PPE to perform their jobs safely and efficiently.

How does your work support our customers?

The alternator gang repairs and rebuilds the alternators that power all the electrical components on Norfolk Southern’s locomotives. Locomotives are what do the actual pulling of the freight cars to deliver the goods to our customers. The alternator is one of the most important and necessary parts of the locomotive.

Safety tip on the job?

Job briefings are the most important and useful tool. We have crew members who have done their job for decades that still do job briefings before every task. This allows people to step back, rethink what is happening and be on the same page. Job briefings not only make everyone safer, but they also help make us more efficient.

Kevin Kelly

Senior General Supervisor

At Norfolk Southern since 2012

What do you do in a typical day?

I manage the day-to-day operations of the engine line, overhaul line, and capital line. I direct priorities for each of these respective lines, getting material and making sure everyone is moving in the right direction. I oversee a team of 170 railroaders who work multiple shifts.

How does your work support our customers?

A lot of our engines we rebuild go to returning locomotives to service. Our team takes locomotives that were once inoperable—sometimes for years—and returns them into the fleet so they can service our customers. The more locomotives we have in operation, the better we can move additional freight and improve network fluidity.

Safety tip on the job?

Locomotives have all sorts of stored energy. That’s why it is paramount to conduct a job safety briefing to safeguard against these hazards.

Chad Vinglas

General Supervisor

At Norfolk Southern since 2007

What do you do in a typical day?

No day is ever the same, but I manage the Traction Motor Shop, Alternator Gang, and AIC system at Juniata. I, along with a few other supervisors, handle the day-to-day production and component requests for all the system shops at NS. The traction motor and wheelset, or combo, is what propels the locomotive, and the alternator provides power to the combo and the rest of the locomotive. We can take a motor, alternator, wheelset, or truck and break it down into its basic parts, refurbish and rebuild those parts, and reassemble them to be better than new. The AIC system is a digital tracking and database software that allows the component shops to track repair and reliability data, as well as production statistics such as dwell time and bottlenecks areas.

How does your job support our customers?

The components we rebuild at Juniata and ship across the system help locomotive shops produce reliable running locomotives. Having a reliable locomotive allows Transportation to deliver on time performance, boosting customer satisfaction. It is our job here to produce quality, reliable components, and if we do not, the customer ultimately suffers for it, so we strive for a high reliability and production rate.

Safety tip on the job?

Whenever you are out on the shop floor, always look both ways and up in case of crane movement. Watch your hand and finger placement, as well as focus on where you are walking. We must make safety first if we are going to be the best.

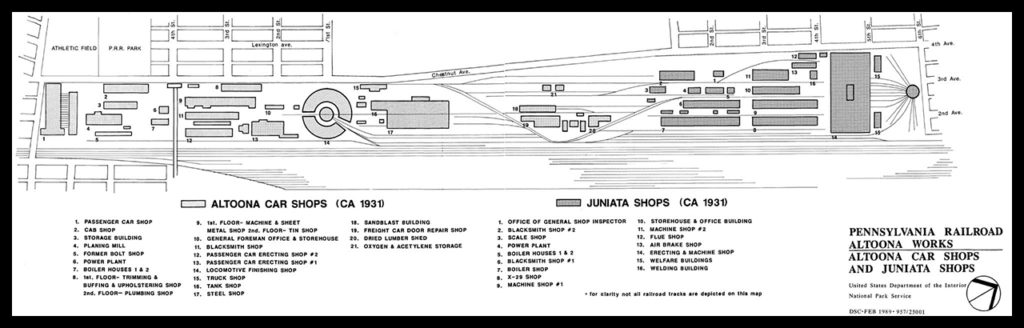

Editor’s Note: NS’s Juniata Shops traces its heritage to the Pennsylvania Railroad and its famous Altoona Works, built between 1850 and 1925 to supply the railroad with locomotives, railcars (both freight and passenger) and related equipment. For many years, it was the largest railroad shop complex in the world. The PRR’s Juniata Locomotive Shop, built between 1888 and 1890 and expanded 1924-1925, constructed steam and electric locomotives from 1891 to 1946. — William C. Vantuono