Greenbrier Multi-Max Plus™: Versatility in Motion

Written by The Greenbrier Companies

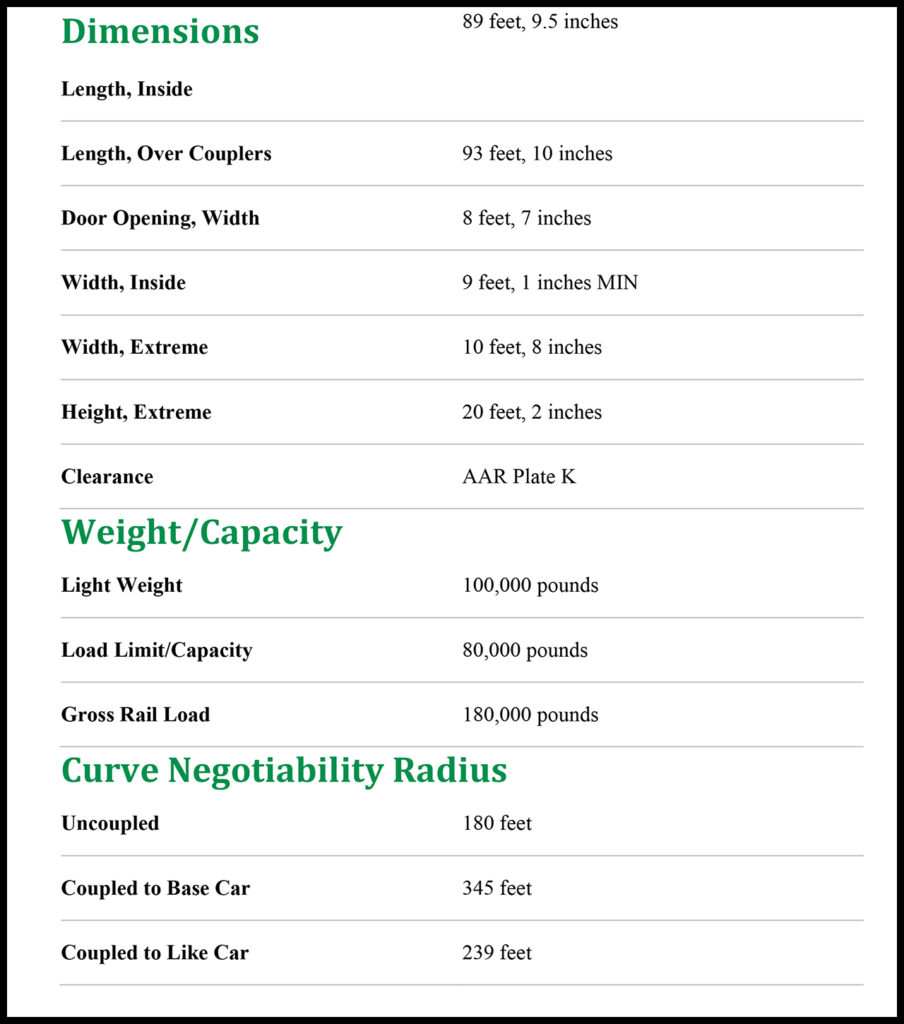

The versatile, bilevel Multi-Max Plus™, designed and built by The Greenbrier Companies, addresses the constantly changing requirements of transporting motor vehicles by rail. Specifically designed to carry tall cargo vans such as the Ford Transit, Mercedes-Benz Sprinter, Stellantis Ram ProMaster, GMC BrightDrop and Rivian EDV 700 and built on our low-level flatcar frame, it has the tallest allowable car height in the industry—Plate K, 20 feet, 2 inches above top-of-rail—a 14-inch height advantage over traditional 19-foot Plate J bilevel auto racks. Unique, rapidly adjustable decks on both ends of the Multi-Max Plus make it “deck-compatible” with Plate J bilevel auto racks, thereby maximizing loading flexibility.

Most motor vehicle OEM builds a tall van, and all use a single-source plant. Greenbrier examined this market and discovered that more than 50% of this business is transported by highway truck, which means many of these tall vehicles are being trucked more than 3,000 miles. The railroads that are handling this business are doing so in single-deck (unilevel) cars or modified standard bilevels, raising the entire deck to accommodate these vehicles. Both railcar types are single-deck loading, with a load factor range between three and four vehicles per railcar. Almost all return to the plant empty. That’s not the best economics for rail transport—certainly not for converting business from truck to rail.

Historically, railroads would specify a railcar with a fixed deck to handle a specific OEM motor vehicle. Tall vans and other vehicles—pickup trucks, SUVs, sedans—are all different, so a “one size fits all” railcar doesn’t address the realities of the market or new business opportunities. The Multi-Max Plus, with its universal deck, increases the load factor to up to nine vehicles—a tremendous improvement in rail vs. truck economics and the opportunity to improve earnings contribution per railcar. It also significantly reduces fuel consumption and CO2 emissions by taking trucks off the highway.

Greenbrier designed the Multi-Max Plus to handle tall vans on the upper deck, and other vehicle types on the lower deck, mostly pickup trucks—successfully testing with every OEM. One might think this feature adds complexity, but we’ve found it’s really the opposite. In terms of equipment utilization, if a motor vehicle plant shuts down for model changeover retooling, stops building a particular type of vehicle or closes completely, the railroad can lose the business to another railroad or to trucks. The railcars are either stored or shopped for a costly deck changeover. Both scenarios can eat up to 50% of a railcar’s lifecycle. At minimum, it can mean 90 to 120 days out of service.

The Multi-Max Plus eliminates this business constraint. It’s 100% deck-compatible with a 19-foot Plate J railcar due to its patent-pending hinged deck, which means it doesn’t need to be shopped. It takes one to two people less than a minute to release and lift the deck to match that of a traditional bilevel autorack. Adjustments may be completed on site at loading locations, saving shippers time and money. As well, Greenbrier’s patented door design greatly reduces the incidence of theft and vandalism by restricting access to the rack interior and roof.

Here’s an example of improved equipment utilization: Stellantis builds ProMasters in Mexico for shipment to the U.S. Midwest. A unilevel or modified standard bilevel would return to Mexico 100% empty for the next load. With the Multi-Max Plus, Stellantis can ship finished Ram 1500 pickup trucks built in Detroit to Mexico. The universal deck provides this railcar with more than one service area. Potentially, it’s the autorack of the future. And while there are still a couple of corridors that aren’t cleared for Plate K—essentially, double-stack intermodal—Greenbrier believes they will eventually be improved to accommodate that height.

Greenbrier’s engineering group worked closely with all the OEMs to design the Multi-Max Plus. Before testing the prototype with each manufacturer, we simulated loading it on our CAD system to make sure all vehicles fit, and that the railcar has an optimal load factor.

The patent-pending hinged deck operates similar to that of a standard trilevel autorack, but with a significant difference. On a trilevel, the B deck end is raised to drive taller vehicles down into the lower section, the A deck. Once the A deck is full, the B deck end is lowered back down and locked it into place for loading.

The Multi-Max Plus, in contrast, is compatible with a standard bilevel with its B deck in the raised position. A vehicle other than a tall van can be driven, parked, secured and transported on the B deck when the deck is locked in the raised position. As such, it may be operated in a consist of standard bilevels, in the same loading string. With the B deck in the raised position, vehicles can be driven straight through it onto a standard Plate J bilevel. We increased the B deck’s structural strength and lifting mechanism just for that purpose. Tall vans are loaded and transported on the B deck, of course, when it’s in the lowered position.

Either way, deck adjustments are quick, whether for loading vehicles with the B deck raised, or lowered for straight-through loading. Depending what’s on the A deck, the B deck may not even need to be raised—thus the optimized load factor.

Greenbrier will start production on Multi-Max Plus at the beginning of 2024. We believe it’s the optimal, most versatile railcar for a dynamic motor vehicle market.

![“This record growth [in fiscal year 2024’s third quarter] is a direct result of our innovative logistic solutions during supply chain disruptions as shippers focus on diversifying their trade lanes,” Port NOLA President and CEO and New Orleans Public Belt (NOPB) CEO Brandy D. Christian said during a May 2 announcement (Port NOLA Photograph)](https://www.railwayage.com/wp-content/uploads/2024/05/portnola-315x168.png)