Class I Briefs: CN, NS, UP

Written by Marybeth Luczak, Executive Editor

CDP has recognized CN for “leadership on climate change.” (CN Photograph)

CN is recognized for “leadership on climate change” by environmental non-profit CDP and for safety at subsidiary CNTL (CN Transportation Ltd.) by ISAAC Instruments. Also, Norfolk Southern (NS) outlines its Conductor Trainee program; and Union Pacific (UP) shares the latest replica of the Big Boy No. 4014, made with 30,000 LEGO® pieces.

CN

CDP has recognized CN for “leadership on climate change,” according to the Class I, which has also been ranked by the 2024 S&P Global Yearbook as a top sustainability performer in the transportation industry.

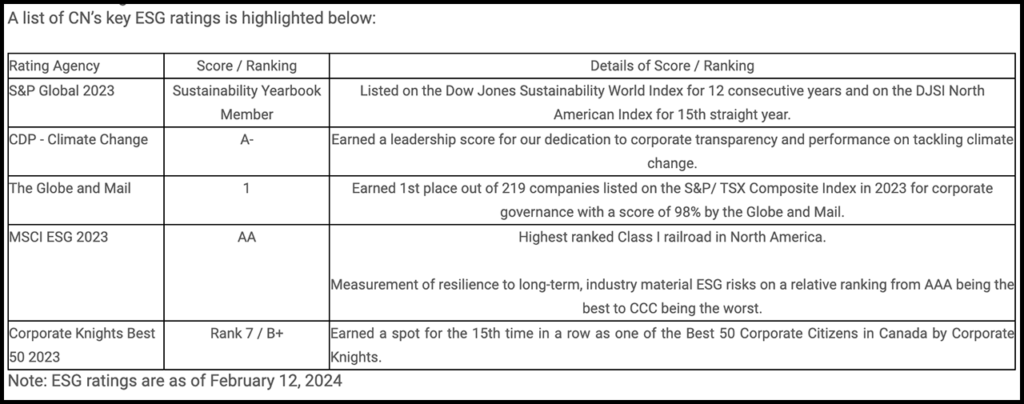

CN on Feb. 12 provided the following list of its ESG (Environmental, Social, and Corporate Governance) ratings:

“Our commitment to Delivering Responsibly leads the way forward for us as an organization,” CN President and CEO Tracy Robinson said. “We are honored to be recognized for our leadership as we work to build a more sustainable future. Our achievements and recognitions are not possible without the dedicated team of railroaders who embed safety and sustainability in every decision.”

The railroad in late 2023 published its latest biennial sustainability report, providing an update on its sustainability strategy and performance. The report detailed its approach to sustainability in the areas of environment, safety, people, community and governance. It was prepared in accordance with “leading sustainability reporting frameworks,” including the Sustainability Accounting Standards Board and the Global Reporting Initiative, according to CN.

Also, CN subsidiary CNTL has recorded a 79% reduction in speeding events; has reduced hours-of-service violations in the United States to zero, and has decreased equipment maintenance costs and upped maintenance service intervals using technology from ISAAC Instruments, which shared the results via LinkedIn on Feb. 12. CNTL has been using ISAAC Coach since 2019.

In a short video released with the LinkedIn post, Brian St. James, Specialist Product Manager for CN, IT, reported that CNTL uses ISAAC Coach to improve fleet compliance and maintenance. “The drivers have found that since they started following the ISAAC Coach instructions, they get a better use of tires and improved maintenance periods for vehicles,” he said. The system has also helped improve fuel economy by 0.2 miles per gallon every year, according to CNTL Regional Manager Lance Schmitke.

Additionally, CNTL uses ISAAC data to improve fleet safety. “We can identify high-risk drivers and help them adopt better driving habits,” reported Franco DiGiacomo, Truck Operation Driver Manager for CNTL in Montreal. Added CNTL Regional Manager of Truck Operations Mitchell Petersen, “[b]y using the ISSAC solution to identity high-risk drivers and interacting with them to reduce their exposure, we’re able to source input from drivers and get the field examples of where we can reduce or eliminate hazards.”

“Thank you ISAAC Instruments and congratulations to the CNTL team!,” CN said in a repost of the ISAAC Instruments LinkedIn report. “At CN, safety is a core value, and this recognition is a testament to our team’s dedication and hard work. Our partnership with ISAAC has been instrumental in helping us elevate safety standards in the industry. Together, we’re driving excellence and powering the economy.”

In a related development, CNTL recently reached a tentative agreement with owner-operators affiliated with Unifor.

NS

Since conductors are “at the heart of providing safe, reliable, and resilient service to our customers,” NS said it is taking additional steps to make sure they are safe and successful on the job.

“We’ve enhanced the curriculum for Conductor Trainees to ensure that they have the skills and knowledge necessary to be safe and successful on the job from Day One,” NS Director of Technical Training Jason Myers said. “Early indicators and feedback are incredibly positive. Program retention levels for CT’s are increasing, setting a promising tone for the year ahead.”

Curriculum design included engaging trainees, conductors, managers, and labor unions for their feedback, according to NS. Based on that feedback, NS is pairing CTs with experienced and willing conductors to act as mentors when CTs report to their hiring locations. This change, among others, NS said, will ensure they receive “an even better learning and onboarding experience.”

The railroad also offers a Ballast Line Leadership Program, which it said “enhances supervisors’ skills in receiving and giving feedback while focusing on leadership development in self-awareness, trust, communication, and collaboration.” The course contributes to improving the railroad’s safety culture, which NS said is a “priority” that it is reinforcing a three-phase, all-encompassing safety improvement program with Atkins Nuclear Secured. According to NS, the program’s expected outcomes are “measurable improvements in the NS safety culture and safety performance, including craft railroader/supervisor/manager/overall organization performance and engagement on safety; better organization focus on continuous improvement through implementation of a coordinated plan; identifying and working on problems while they are small in order to reduce the likelihood of problem recurrence and consequences; and strengthened organizational learning.”

For more on NS conductor training and workforce initiatives, listen to the Rail Group On Air podcast with Executive Vice President and Chief Operating Officer Paul Duncan.

UP

UP’s Big Boy No. 4014 was showcased in a new way at the recent Atlanta Brick Con (see above). LEGO® fan Mark Staffa displayed a 20-foot-long replica that he created from 30,000 LEGO pieces. The 1/7th-scale model took the builder seven years to complete.

This is not the first LEGO model of the largest steam locomotive ever built. Lasse Hvidtfeldt of Denmark designed and built a three-foot-long replica using 2,656 LEGO bricks. The work, displayed in 2022 on the LEGO Ideas webpage, required 762 instruction steps and 300 hours to complete.

UP’s Big Boy, part of its heritage fleet, will return to the rails in 2024 for a tour that UP said will celebrate the railroad’s history and connection to communities, and its employees. The tour is expected to reach all four corners of UP’s 23-state network, with anticipated stops in Chicago, Ill.; Dallas/Ft. Worth and Houston, Tex.; Nampa, Idaho; Portland, Ore.; Roseville, Calif.; and Salt Lake City, Utah.

Tour dates and route information will be released later this year. In addition to public stops, UP employees and their families will be invited along the route.

American Locomotive Company (ALCO) manufactured 25 Big Boys for UP. The first was delivered in 1941 to haul heavy trains over the Wasatch Mountains between Ogden, Utah, and Green River, Wyo., on a 1.14% ruling grade; 19 others were delivered the same year and five in 1944. As the story goes, the 4000-class series originally was to have been designated the “Wasatch,” but an unidentified ALCO worker wrote “Big Boy” in chalk on the smokebox of one unit during construction, and that’s the nickname that stuck.

The units saw service until their fires were dropped for the last time in 1961. Eight survived. No. 4014 is the only Big Boy in operation; the other seven are on display in Cheyenne; Denver, Colo.; Frisco, Tex.; Green Bay, Wis.; Omaha, Neb.; Scranton, Pa.; and St. Louis, Mo.

UP reacquired No. 4014 in 2013 from the RailGiants Museum of Pomona, Calif, and set out on a five-year restoration at UP’s Steam Shop. (The locomotive had been in retirement for six decades previously). In 2019, the unit ran in the “Great Race” tours commemorating the 150th anniversary of the transcontinental railroad’s completion.

A nine-page Railway Age article of Oct. 4, 1941 (download below) describes the Big Boy in full technical detail. Also for download: elevation and cross-section technical drawings.