Crashworthiness for Alternative Fuel Powered Vehicles

Written by Przemyslaw Rakoczy, Senior Research Engineer, ENSCO, Inc., and Matthew Dick, P.E., Chief of Strategy & Development, ENSCO, Inc.

TTC Operated by ENSCO, RAILWAY AGE, AUGUST 2023 ISSUE: Following the global movement to reduce emissions and, ideally, use renewable energy instead of diesel fuel, the rail industry is looking for alternative means to propel future trains.

One of the major current areas of development and research in the rail industry is alternative fuels, such as hydrogen, Renewable Natural Gas (RNG), and other means to store energy, such as Battery Energy Storage Systems (BESS). This shift to new fuels and energy storage systems brings the necessity to review and, in some cases, update current crashworthiness requirements and test protocols to ensure safe operation and reduce the consequences of extreme events, such as derailments and collisions.

Alternative fuels

Several alternative fuels are currently being evaluated to replace diesel, each with the advantage of lower or zero emissions. However, they also have important characteristics that must be addressed. Liquefied Natural Gas (LNG) is one of the first alternative fuels considered by the rail industry. Natural gas burns significantly cleaner and produces lower emissions of sulfur, nitrogen, and carbon dioxide into the atmosphere as compared to diesel.

The volume energy density of LNG is 40% of diesel and therefore requires an LNG tender for the same train range. Moreover, LNG needs to be stored in cryogenic tanks. To avoid the cryogenic storage challenges, Compressed Natural Gas (CNG) is also considered. The volume energy density of CNG is lower than diesel, which requires the use of fuel tenders for long-haul operations. RNG is biogas that is manufactured to have similar performance to fossil natural gas but has further lowered emissions.

A very promising alternative fuel considered is hydrogen, which can be produced in the electrolysis from water and turned back into water in fuel cells to produce electricity. This makes hydrogen powered rail vehicles virtually emission-free if the hydrogen is produced using renewable energy sources, such as photovoltaic or wind power plants. Like natural gas, the volume energy density of cryogenic liquid and compressed gas hydrogen is lower than diesel, which requires the use of fuel tenders for long-haul operations.

Another solution to propel the trains is BESS (Battery Energy Storage System), which typically uses lithium-based battery packs. The benefit of the BESS is that there are no emissions from the vehicles. The disadvantage is the limited range and time necessary to charge the batteries. However, it is a valuable alternative that could be advantageous in certain applications.

Rail Crashworthiness

Railroads and suppliers introducing alternative fuel locomotives and passenger trains must comply with multiple applicable requirements in the Title 49, Code of Federal Regulations, particularly Part 229, Railroad Locomotive Safety Standards, and Part 238, Passenger Equipment Safety Standards. Both Safety Standards include various minimal crashworthiness requirements. Additionally, the Locomotive Safety Standard incorporates Association of American Railroads (AAR) S–580, “Locomotive Crashworthiness Requirements” and includes Appendix E, “Performance Criteria for Locomotive Crashworthiness.” The Passenger Safety Standards include very detailed requirements regarding crashworthiness of various types of equipment, including Power Modules and passenger portions of multiple-unit railcars. To operate alternative fuel equipment, railroads and suppliers must demonstrate to the FRA that their equipment complies with these requirements.

There are multiple aspects of rail crashworthiness that should be considered with respect to alternative fuels. One aspect is impact resistance. For example, head-on and side impacts that can cover multiple impact scenarios, in particular collisions with heavy road vehicles at grade crossings. Another aspect is crashworthiness during derailments. The risks and mitigation of consequences associated with damage and release of alternative fuels must also be evaluated. There are other unique crashworthiness scenarios that have to be considered, depending on the type of rail service, configuration of the train consist and design of the alternative fuel vehicle.

Certain crashworthiness research, tests and specifications have already been conducted and developed. The AAR developed crashworthiness requirements for LNG fuel tenders in the M-1004 standard, which provides a grade crossing impact case scenario between the LNG tender and an 80,000-pound truck at 40 mph. In 2021, the Federal Railroad Administration (FRA) conducted a full-scale test at the Transportation Technology Center (TTC) replicating the AAR M-1004 case scenario. As a result of the impact, the track structure supporting the tender and locomotives experienced tie shift and rail rollover, resulting in the derailment of both tender trucks and one truck of each locomotive. However, no puncture nor damage resulting in the commodity release occurred. Moreover, the safety shutoff valve was successfully closed, demonstrating the ability to cut fuel supply to the locomotives even after a grade crossing impact on the tender. This test demonstrated that the fuel tenders won’t release the fuel even under extreme load conditions.[1]

The FRA also evaluated the puncture resistance of the cryogenic tank cars through simulations and full-scale tests at the TTC. This includes tests with liquid nitrogen to determine the influence of the extremely low temperatures on material and puncture resistance. This research is also applicable to the transportation of liquified hydrogen.[2]

Compressed gases, especially CNG, are used to propel urban buses in many cities around the world. There has already been significant research conducted, including drop and fire tests of the bus storage tanks. However, further research is needed to evaluate the safety of these tanks in the rail environment.

Future Research

Despite the work that was conducted for the LNG fuel tenders and transportation of this fuel by rail, there is still work to be done. Alternative fuels and BESS create new challenges that need to be assessed, evaluated and mitigated.

The lithium batteries used in BESS are at risk of thermal runaways if damaged or overheated. Crashworthiness protection of the battery packs will need to be evaluated by testing to make sure they won’t be damaged or otherwise compromised during crash or derailment.

Similarly, additional tests and simulations are necessary to evaluate the safe operation of compressed or liquid hydrogen storage tanks, piping and valves in dynamic impact load conditions. The storage tanks, together with the protective structure, should also be evaluated for crashworthiness in the railway environment.

The TTC has multiple laboratory and field equipment specifically designed to evaluate crashworthiness of various types of equipment under different scenarios. This includes an impact wall qualified for three million pounds of impact accompanied with a ram car. The facility is also equipped with a squeeze test fixture that provides up to three million pounds of longitudinal force. One of the specific challenges associated with gaseous fuels, such as LNG, CNG and hydrogen, is the prevention of fire and explosions during accidents in enclosed or partially enclosed environments, including tunnels, long underpasses, etc. This is an area that will require additional analysis, simulations and tests. The TTC has a 300-foot-long underground tunnel specifically designed and qualified to conduct blast, fire and smoke testing in conditions maximally resembling a real environment.

Summary

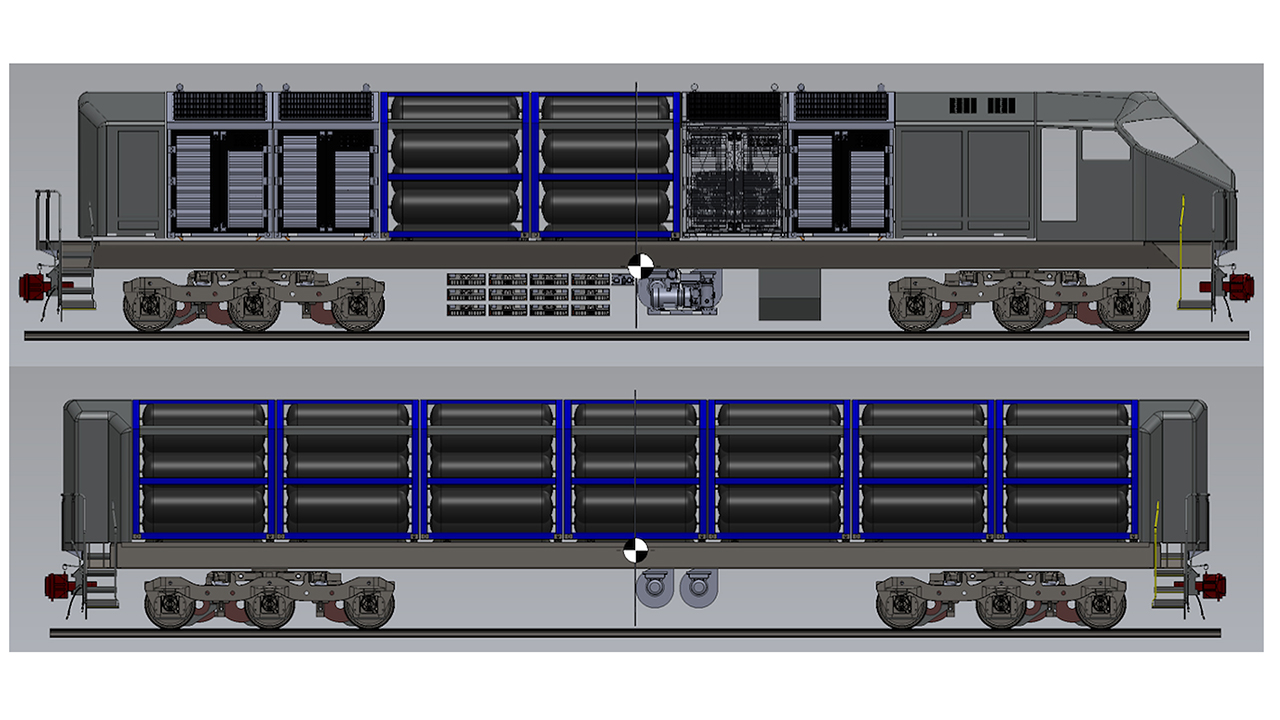

Alternative fuel and battery-powered trains are already being introduced to the rail network. These vehicles present the opportunity to meet greenhouse gas emission reduction goals. However, it is important that their crashworthiness safety is assured for their safe operation. Further research, including testing and simulation, is necessary to ensure a similar or increased safety compared to legacy technology. The TTC has played a major role in providing a technical basis for crashworthiness assessments in the past and is ready to provide similar services in the changing future. The TTC is ready to aid these alternative fuel and battery-powered train suppliers, (such as OptiFuel’s locomotive and tender shown in the picture) to ensure safe operations while reducing emissions.

References

[1] Highway-Rail Grade Crossing Collision Test of a Fuel Tender, FRA RR 21-24, November 2021.

[2] Full-Scale Shell Impact Test of a DOT-113C120W9 Tank Car Filled with Liquid Nitrogen, FRA RR 22-10, July 2022.