CN: ‘Keeping it Fresh’

Written by Marybeth Luczak, Executive Editor

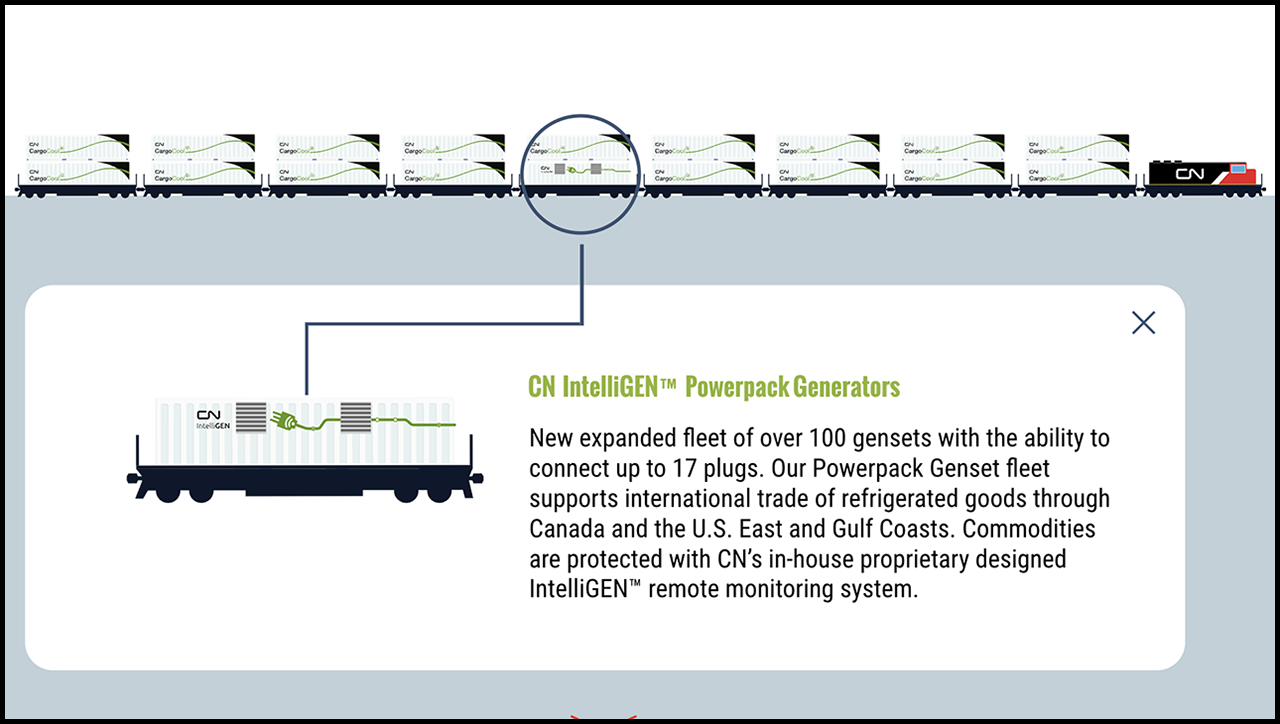

“By using state-of-the-art equipment and temperature-monitoring technology, CN’s IntelliGEN™ genset fleet manages the flow of electric power to the reefer containers while in transit to ensure that products reach their destination safely, on time, and at the right temperature,” according to the Class I. (Image Courtesy of CN)

CN is using its IntelliGEN™ genset fleet to ensure that customer products reach their destination “safely, on time and at the right temperature.”

CMA CGM last year turned to CN to move approximately 27,000 tons of Moroccan citrus from Tangier, Morocco, directly to key Canadian consumer markets in just 10-11 days, the Class I railroad reported Feb. 26 on its website. This was an improvement, the railroad said, over CMA CGM’s previous arrangement to a U.S. East Coast port where the fruit had to be trucked into Canada.

The supply chain solution involved loading the Moroccan citrus into CMA CGM reefer containers leaving by vessel from the Port of Tangier to the Port of Halifax, according to CN. From there, the cargo was unloaded directly from the vessel onto trains departing the same day for consumer markets in Montreal and Toronto. Sensitive citrus fruit, which includes oranges and clementines, is kept at 3 degrees C along the inland journey with CN’s Temperature Controlled Cargo service.

“By using state-of-the-art equipment and temperature-monitoring technology, CN’s IntelliGEN™ genset fleet manages the flow of electric power to the reefer containers while in transit to ensure that products reach their destination safely, on time, and at the right temperature,” the Class I reported.

CN has more than 100 gensets with the ability to connect up to 17 plugs. “Our Powerpack Genset fleet supports international trade of refrigerated goods through Canada and the U.S. East and Gulf Coasts,” according to the railroad. “Commodities are protected with CN’s in-house proprietary designed IntelliGEN™ remote monitoring system.”

CN worked with CMA CGM and port operator PSA Halifax to coordinate the operating plan and “timely execution” of cargo movement.

“It has been a fantastic collaboration,” CMA CGM General Manager Thiago Campos said. “We had a short time frame in which to work but the full support of the CN team and PSA Halifax meant we could deliver the freshest produce possible to consumers and always ensure a quality product.”

Simon Lemay of Courchesne Larose Ltd., a Canadian distributor of fresh fruit and vegetables, told CN: “We are in a time-sensitive business of fresh produce imports. Our goal is to bring freshness from the orchard to the table. From vessel to rail, CMA CGM and CN worked hand-in-hand to provide us with outstanding service, respecting the delivery schedule.

“The collaboration of CN, PSA Halifax, and CMA CGM throughout the five-six months of the project was outstanding,” added Todd Protheroe, CCLP, Commercial Manager at PSA Halifax. “We were able to deliver superior value by increasing the shelf life of the citrus compared to the previous model.”

CN also uses its Intelligen™ genset technology in its work with Olymel, a Canadian company that produces, processes, and distributes pork and poultry meat, exporting its products to more than 65 countries, including major markets in China, Japan, and South Korea, in addition to serving the Canadian market. From its plants in southern Quebec, chilled pork is transferred by refrigerated containers to CN’s Taschereau Yard, where the reefers are sent by rail to the Port of Vancouver and loaded onto shipping vessels, CN reported on its website last fall. The shelf life of the pork from the slaughterhouse to the consumer in Asia is 60 days.

“It’s vital to maintain the cold chain for this type of product along the entire journey,” said Gabriel Savoie, Director, Exports at Olymel. “CN is always on the lookout for solutions to enable us to maintain our quality standards, and can intervene to reduce delays or in the event of a problem.”

![“This record growth [in fiscal year 2024’s third quarter] is a direct result of our innovative logistic solutions during supply chain disruptions as shippers focus on diversifying their trade lanes,” Port NOLA President and CEO and New Orleans Public Belt (NOPB) CEO Brandy D. Christian said during a May 2 announcement (Port NOLA Photograph)](https://www.railwayage.com/wp-content/uploads/2024/05/portnola-315x168.png)