East Palestine: NTSB Examining Tank Car Hatch Covers

Written by Carolina Worrell, Senior Editor

Aerial photograph of derailment site, courtesy of the NTSB.

Following the completion of damage assessment inspections of the 11 Norfolk Southern (NS) hazardous materials (hazmat) tank cars, including the five carrying vinyl chloride, that derailed in East Palestine, Ohio, on Feb. 3, the National Transportation Safety Board (NTSB) says it is “concerned that aluminum protective housing covers on some tank cars melted or were consumed when pressure relief devices (PRDs) vented burning gas while functioning as designed to relieve tank pressure.”

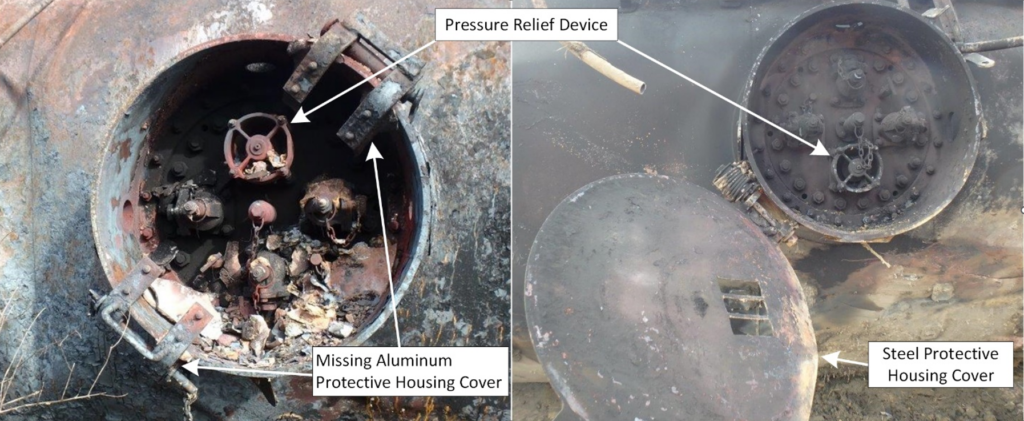

The five derailed railcars carrying vinyl chloride were DOT-105J300W tank cars. Preliminary examination, which was completed Feb. 22 and released Feb. 23, suggests that melted aluminum may have dripped into some PRDs, possibly degrading their performance (see Figure 1, below), according to NTSB. The tank car wreckage was released to NS on Feb 24.

According to NTSB, when a tank car is exposed to fire conditions and its contents are heated, the pressure inside the tank rises. This, NTSB says, “can lead to loss of tank shell strength and eventually a breach. To protect emergency responders and the public from the possibility of catastrophic tank failure under fire conditions, the pressure inside tank cars must be controlled. PRDs are intended to regulate internal pressure by releasing small quantities of material and reclosing after normal conditions are restored. This reduces the probability of a breach in the tank shell and limits the amount of energy a breach can release if one occurs. Properly functioning PRDs thus reduce the potential for catastrophic tank failure.” Figure 2 (below) illustrates PRD function during the East Palestine derailment.

According to the preliminary investigation, NTSB discovered that three of the examined derailed vinyl chloride tank cars were manufactured in the 1990s with aluminum protective housing covers. Although the number of tank cars in flammable gas service with aluminum protective housing covers is presently unknown, NTSB has requested industry data to determine the size of the potentially affected fleet.

According to NTSB, PRD and valve assemblies recovered from the five vinyl chloride tank cars are being delivered to a testing facility where investigators will further examine them during the week of March 13, for conditions that might have affected their operation following the derailment in East Palestine, Ohio.

NTSB is conducting a safety investigation to determine the probable cause of the derailment and issue any safety recommendations, if necessary, to prevent future derailments. NTSB can also issue urgent recommendations at any point during the investigation.

While the NTSB investigation into the derailment is ongoing, the Pipeline and Hazardous Materials Safety Administration (PHMSA) has issued a Safety Advisory (download below) to “encourage all hazmat tank car owners and offerors to survey their fleets for any tank car currently equipped with aluminum protective housing and consider replacing this equipment with carbon steel housing.”

According to the Safety Advisory, PHMSA and the Federal Railway Administration (FRA) “may take additional action in the future if investigations reveal that the destruction of the aluminum manway covers and presence of melted aluminum inside the protective housing significantly contributed to improper functioning of the pressure relief devices.”