Long-Travel Draft System Impact Testing

Written by Mitch Miller, Senior Engineer, and Adam Klopp, Principal Investigator II, MxV Rail (formerly TTCI)

Bruce Kelly photo

RAILWAY AGE, MAY 2022 ISSUE: Under the Association of American Railroads (AAR) Strategic Research Initiatives (SRI) program, MxV Rail (formerly TTCI) is conducting research to characterize, evaluate and improve the performance of long-travel draft systems. Draft systems protect railcars as coupler forces are transmitted through a train by controlling relative motion between coupled cars and absorbing energy during impacts.

These systems are typically evaluated using drop hammer tests or impact tests based on the AAR Manual of Standards and Recommended Practices (MSRP). These types of tests show how draft systems absorb energy in car-to-car impact events, and they can be used to derive draft system performance characteristics that can be used to model in-train operating scenarios. Four types of draft systems were evaluated under the SRI program: 1) a standard hydraulic, 15-inch, end-of-car cushioning (EOCC) unit; 2) a 15-inch EOCC unit with active draft; 3) a friction draft gear; and 4) a non-hydraulic, long-travel unit.

EOCC units are a type of draft system that absorbs energy from applied coupler loads over a long displacement stroke. Due to their long displacement stroke, these units provide excellent impact protection for cars and lading in high-force, high-acceleration yard environments, but they can cause slack action issues during over-the-road (OTR) train operations. In contrast with standard EOCC units, EOCC units with active draft have slightly reduced buff travel and provide additional draft protection from the neutral position to potentially improve in-train performance. Friction draft gears use a combination of spring and friction elements to both control the relative motion between cars and absorb energy. These gears do not provide the same level of impact protection as EOCC units, but, due in part to a shorter displacement stroke, these gears typically provide better control of in-train forces and slack action during normal OTR operations. The non-hydraulic long-travel unit tested in this program provides improved energy absorption capacity over a standard draft gear using a shorter displacement stroke than a typical EOCC unit.

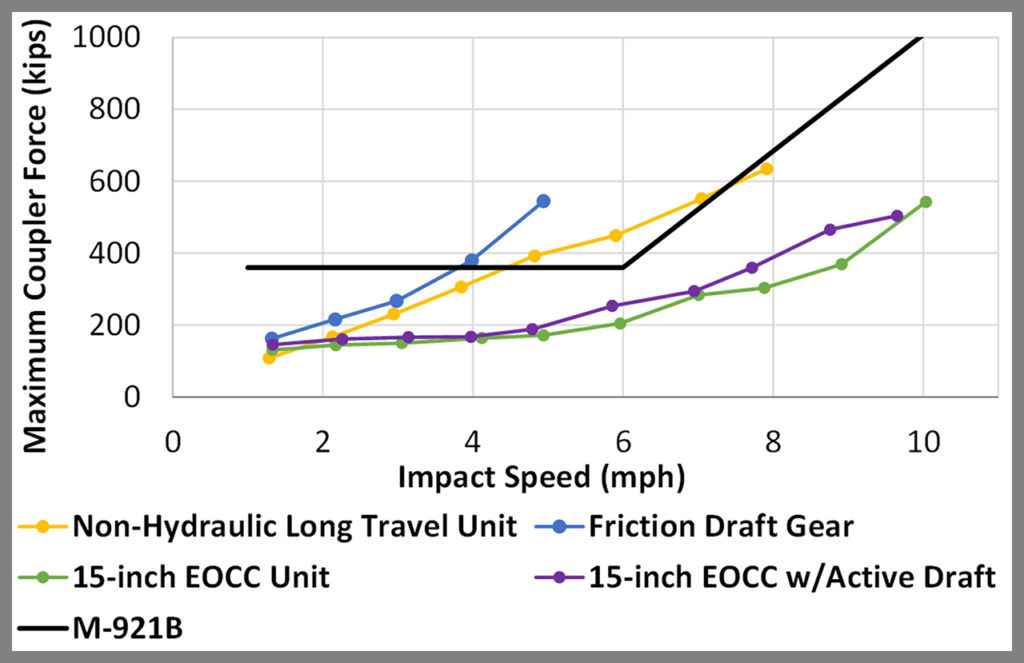

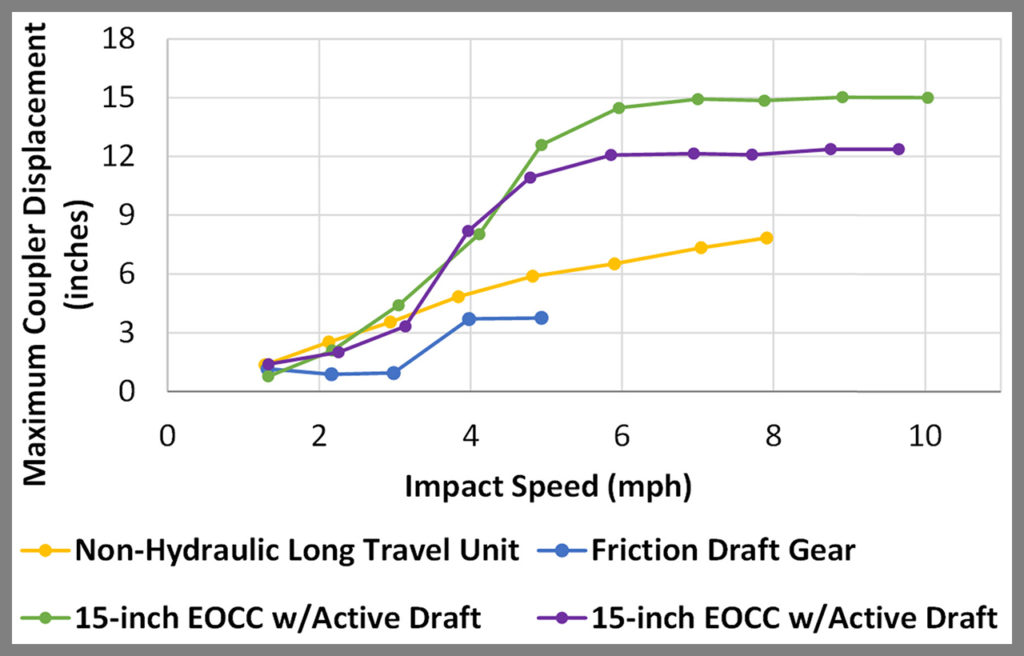

MxV Rail conducted impact tests according to the M-921B standard from the AAR’s MSRP. The figures below show selected results from these impact tests.

The impact results showed that the standard 15-inch EOCC unit provided the lowest forces and accelerations in the tests because it was able to absorb more energy over its long displacement stroke. The 15-inch EOCC unit with active draft provided a similar level of impact protection as the standard EOCC unit despite a slightly decreased displacement stroke. The results of the friction draft gear impact test showed a decrease in impact performance compared with the EOCC units, including higher forces and accelerations, due to its smaller displacement stroke and limited energy absorption capacity. The non-hydraulic long-travel unit provided more impact protection than the friction draft gear, and this system nearly met the M-921B impact performance for evaluating hydraulic EOCC units.

Impact and drop hammer tests are necessary to evaluate the performance of draft systems because these tests show how draft systems absorb energy in car-to-car impact scenarios. However, these tests do not provide much insight into how the systems will perform in OTR environments where train action issues can occur. To address this challenge, MxV Rail is using a combination of physical impact tests and simulations to evaluate the energy management and slack control ability of different draft systems. Data from car-to-car impact tests are being used to develop the draft systems models that will be used to simulate challenging operating scenarios and provide a more complete picture of the draft system performance.