2014 Railway Age Guide to Equipment Leasing

Written by William C. Vantuono, Editor-in-ChiefWelcome to the 2014 Railway Age Guide to Equipment Leasing. This special report is devoted to the railcar market, specifically to the lease market for general-purpose and tank cars.

Market Overview

The railcar market continues to follow a trend of outrageous demand in some car types mixed with tepid demand in others. With a current backlog (as of the end of 1Q2014) of almost 82,000 cars, demand is strong for covered hoppers and tank cars with light to no building of other car types. The regulatory environment for tank cars remains unsettled, and that is impacting railcar markets and lease rates. The continued availability of cheap capital for investors in rail assets is fueling investments in rail from all over the marketplace. There are new operating lessors funded by a variety of monetary sources, private equity firms, and bank leasing companies—all competing for the same transactions in the marketplace.

All in all, the leasing marketplace for rail equipment is volatile, aggressive, and hungry.

Covered hopper market explosion

The recent run-up in demand for covered hoppers of all types has been both incredible and insatiable. While demand for cars used in hauling sand and cement was on the rise in the latter part of 2013, there has been a significant market shift and demand increase driving an order backlog and lease rate market that is extraordinary. There have been several residual effects from the run-up in orders of sand/cement hoppers. One, covered hopper cars of all types have seen an increase in demand. This includes covered hoppers for plastic pellets and grain. Two, the intensity of the demand has driven lease rates for all three primary types of covered hoppers higher. Three, there has been an increase in concern about the potential for overbuilding in these markets. In 1Q2014, more than 12,000 covered hopper cars were added to the manufacturing backlog.

In spite of overbuilding concerns, the backlog for covered hopper cars of all types is strong. After a short-lived pullback in demand in 2013, in 1Q2014, more than 10,000 small-cube covered hopper cars (for hauling sand and cement) were added to the manufacturing backlog. That is an increase of 15% over the current small cube covered hopper railcar fleet. This increase has pushed the manufacturing backlog for this car type out into 2015 and on the threshold of 2016.

Anecdotal descriptions of multiple-thousand-plus car orders are rife within the market both from end users and the operating lessors.

For plastic pellet hoppers, the identified target zone of late 2015 into 2016 is fast approaching. Large orders of plastic pellet hoppers placed for delivery beginning mid-2015 have already been awarded, and there are various large-scale projects and orders ready to be placed for delivery in 2016 and into 2017.

Orders for this car type also include orders from operating lessors. On the grain side, 2013’s strong harvest and shrinking manufacturing capacity has companies scrambling to grab capacity wherever it is available.

Market Intelligence is suggesting that some builders may have sold out manufacturing lines for covered hopper production through December 2015.

For many investors, covered hopper cars may represent a safe haven from the tumultuous regulatory environment of tank cars. In practical terms, any company hoping to build a covered hopper car of any capacity before Jan. 1, 2016, needs to be in process for placing those orders today.

The market drivers for this level of demand are pretty straightforward, and many of them relate to circumstances the are direct or indirect results of the intense growth of hydraulic fracking and the low price of natural gas. Chemically treated sand is an integral component of the frac drilling process. More wells, or more drilling into existing wells, requires more sand. Natural gas, the off-take from the wells, is plentiful and has stayed at a price that is reasonable.

Cheaper fuel prices are driving domestic industrial growth. Plastics production in North America will add capacity in large numbers from 2015 to 2017. For grain demand, an aging fleet of older assets, a few years of underbuilding during the economic downturn, some sharing of that older fleet (4,750-cubic-foot cars) with the market for sand cars and a general increase in overall demand has driven a surge in demand for grain hoppers of all sizes.

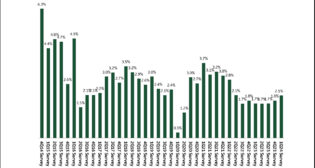

What has the demand dynamics done to lease rates for these cars? In what will be a recurring theme in the discussions on all car types in this issue, lease rates frequently follow the manufacturing demand curve. In other words, the more demand that exists for a car, the higher the lease rate is likely to be. The chart on page 16 shows the changes over the past twelve months in operating lease rates for a variety of covered hopper cars. I spoke with industry sources to obtain these rates. The rates listed below are per car per month for a five-year full service lease payable monthly in advance.

These prices reflect the increase in demand for certain car types and the influx of capital and competition that continue to drive pricing in the marketplace. In a sense, it seems almost counter-intuitive. With demand so far ahead of supply, end users of equipment might expect a more robust surge in lease rates to account for the demand overhang. So far, the lease marketplace has not shown an instinct to stretch out and press rates to the types of historical levels typically representative of the supply and demand imbalance.

None of the lessors with whom I spoke had any explanation for this circumstance other than noting that the market lacked the backbone or “chops” to push through price increases and risk pushing end users to source their own cars rather than lease cars from operating lessors. If this is true, and there’s no reason to believe it is not true, this hesitation to drive price increases is not opportunistic. Rather, it demonstrates a belief in the long-term demand curve for these cars and the markets that they serve. In other words, this demand surge is driven by growth and not by any service-related slowdown creating short-term demand.

Could the backlog for hopper cars reach 24 months? A full sellout of all hopper car manufacturing capacity for that period of time seems unlikely. Certain car types, such as plastic pellet covered hoppers, might become more difficult to find in that timeframe as orders get placed for new facilities coming on line in 2016 and 2017. As new car prices continue to advance, look for an additional surge in the pricing on used cars in these markets for cars that are of modern capacity (286 GRL).

In the eye of the tank

The regulatory environment for tank cars continues to generate industry buzz. Talk to three different insiders on three different days and you will find three different points of view on the where, when, and how of tank car regulation. The only thing that everyone agrees on is the why, so let’s start there.

In case you have held out on reading any other industry information about the tank car market, here’s a 30,000 foot summary. As a result of derailments with unit trains, crude oil tank car design requires modification and upgrading to improve safety. The scope and timing of these improvements remains unknown at this time.

In spite of all of the pending U.S. Department of Transportation changes, tank cars continue to be ordered and built at a tremendous pace. Based on the most recent ARCI data, there were roughly 4,700 tank cars ordered in 1Q2014 while there were roughly 8,900 built. Both of these data points are consistent with calendar quarter 4Q2013. Annualize these numbers and the data is astounding: Annual backlog added is roughly 19,000 cars and the annual build rate is roughly 35,000 cars. One tank car builder is rumored to have backlog orders out past mid-2016. Historically, the tank car annual build rate has been closer to 9,000 cars. All of this is occurring while the industry is contemplating broad sweeping design changes in its primary tank car designs. The difference in cars built and cars ordered may seem to indicate some reticence for new orders as the industry waits for the DOT.

The lease marketplace for tank cars is exhibiting its own brand of concern in the face of current uncertainty. We have heard from multiple sources that many leasing companies (banks and operating lessors) are sitting on their hands in regard to the manufacturing, purchase, and leasing of DOT-111As until the modifications have been announced and confirmed. It’s a position that makes sense. With the cost of modifying a car potentially doubling (to as high as $30,000) once a car has been built, investors would want to build the car that has the DOT stamp of approval. Key components of the expected changes such as the timeline for implementation and the potential for grandfathering of some existing tank cars are also unknown.

What is a lessor to do? Most tank cars leased by operating lessors (builders such as ARI, Trinity, or Union Tank Car, and finance companies such as CIT, First Union Rail, GATX, and GE Railcar Services) are leased in a full-service lease structure. A typical full-service lease covers mandatory changes to equipment using a mechanism to increase lease rates based on the cost of the modification. However, the potential cost impact of the current DOT changes may spark a number of potentially heated debates among lessees and lessors on exactly who should be responsible for the lion’s share of the modification costs presently contemplated.

Lease Rates

What has this done to lease rates generally on a five-year, full-service basis? Rates have retreated slightly from the highs that were common in mid-2013 (rumored at around $2,500 per car per month). Current seven-year, full-service lease rates for 31,000-gallon non-coiled, non-insulated tank cars (the standard Bakken crude car) are around $1,600 per car per month depending on the quantity, availability, and specification. For the coiled and insulated 25,500-gallon car, the seven-year, full-service lease rate is around $1,750 per car per month, again dependant on the same variables. It is difficult to peg year-over-year comparable rates as the volatility in the market has seen high rates that may have been unsustainable. The tank car build is not limited to the DOT-111A cars and this supports the additional demand.

The rest of the story

Lest any reader think that the entire railcar world revolves around tank cars and covered hoppers, here’s a rundown on the rest of the car market and what the rest of the lease marketplace for railcars looks like.

Coal cars: Coal has seen a surge in demand and of cars moving into service starting back toward the beginning of 2014. Cars that sat idle for one to three years have moved back into service and are earning revenue. The demand for coal equipment in the face of a consistent source of reasonably priced natural gas can be traced to two primary factors: coal’s scale in the overall market and train velocity. Even with all of the discussions on crude and natural gas, coal is still a rail king, accounting for 40% of all non-intermodal carloads year to date.

Lease rates? Five-year, full-service rates are running in the high $300s for gondola cars and low $400s for rapid-discharge hopper cars. Is the run sustainable? Sources suggest that this market holds water until 2016.

Boxcars: The boxcar market has held mostly level during the past 12 months. Other than a few orders built by TTX, the leasing community has stayed away from building into this market. Steep pricing (think $130,000 or so for a new 50-foot Plate F box) and few projections for growth keep investors from jumping in. The biggest boxcar news is the GATX purchase of the GE Railcar Services per diem fleet and the confidence that purchase shows in the long-term prospects for segments of this market. If there is a lease opportunity, lease rates run in the mid $600s five-years, full-service—not a market for the faint of heart.

Mill and covered coil gondolas: Cars for steel hold the same place as boxcars in the lease market today. After several turns as being the next car to go boom in the market, the market seems to have finally accepted that at today’s new car prices ($90,000-plus for a modern 286 GRL car), rental rates will not support investment in new equipment. There has been some spot building in the past few years (again a large portion by TTX, especially of the 66-foot western railroad scrap car), but nothing along the lines that would support a strong increase in the total fleet for this car type.

Five-year, full-service lease rates on modern capacity cars are running in the mid $500s depending on age, condition, and size (52-foot vs. 66-foot). If the lease rates were to improve from current levels, there may be some opportunities for growth with today’s capital interest rate environment. What’s one of the challenges? Getting a manufacturer to build a small group of these cars in the current manufacturing environment. On the hunt for gons? Look to the secondary market for investment opportunities and diversification.

Intermodal cars: Intermodal continues to be a bright spot. There is building of new equipment for growth and fleet rejuvenation. 2014 intermodal loads will top five million soon and are right now running at a 5% improvement over 2013. The lease market for these cars is thin. The primary market here is TTX acquiring flat cars and autoracks from the manufacturers. However, if an operating lessor has the “right” asset type, that can lead to the type of long-term leasing relationship that lessors love. Be prepared: The buy-in cost is high. Think $285,000 for a five-unit articulated 40-foot doublestack car. In love with the 53-foot car? Be prepared to pay $195,000 for an articulated three-unit car.

Overall, the general market shows a bit of a disconnect between car pricing and lease rentals. Other than the covered hopper market and the tank market, lease rentals and new car prices are not moving in tandem. Savvy buyers should be looking for opportunities for lease and purchase with eyes open. Have your checkbook out. Opportunities are unlikely to last, so grab them when you see them.

Have questions? Set them free at [email protected]