Wabtec’s Kumar: ‘Innovating With Purpose’

Written by Marybeth Luczak, Executive Editor

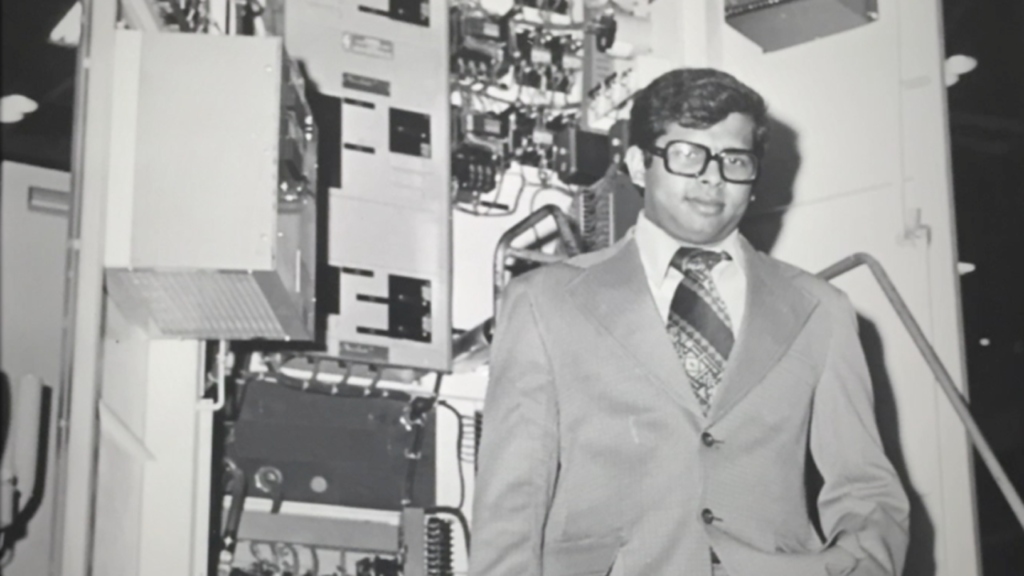

AJ Kumar (seated) joined GE Transportation—now Wabtec—in 1977, and recently earned his 362nd patent. (Photograph Courtesy of Wabtec)

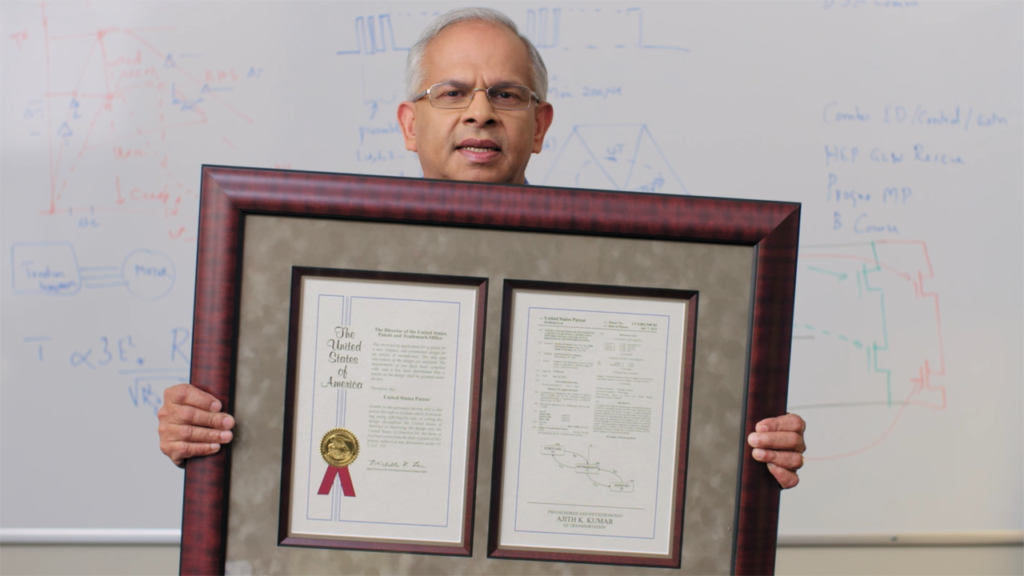

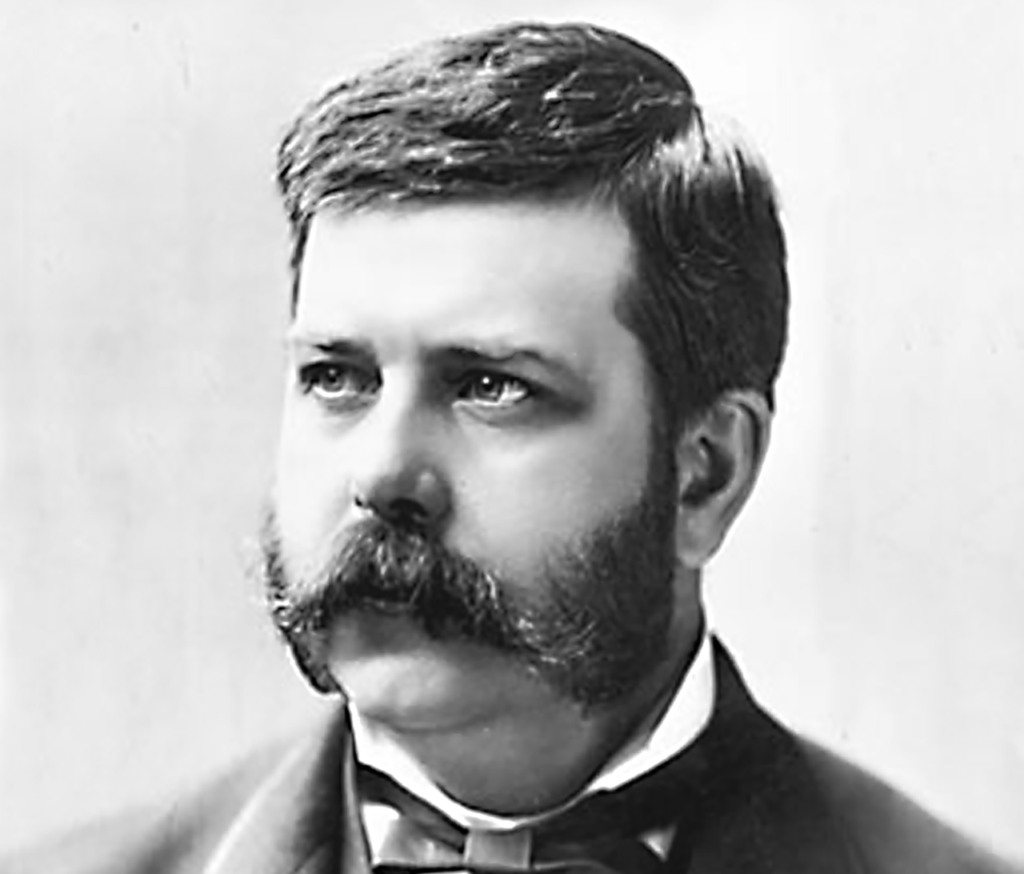

Ajith (“AJ”) Kumar recently received his 362nd U.S. patent. He is Vice President Technology-Innovation for Wabtec, whose origins began in Western Pennsylvania with founder George Westinghouse Jr.’s invention of the automatic air brake in 1869. For surpassing Westinghouse’s patent record, 361, Kumar was honored during Wabtec’s Sept. 1 all-hands meeting.

Kumar grew up in Trivandrum, India, and earned his bachelor’s and master’s degrees in electrical engineering at the College of Engineering in Trivandrum and at Stanford University in California, respectively. In 1977, his classroom became General Electric, whose GE Transportation business unit comprising equipment, services and digital solutions in the locomotive, mining, marine, stationary power and drilling industries was acquired by Wabtec in 2019.

Kumar was instrumental in developing for GE a brand-new locomotive propulsion system in the 1990s—taking standard DC traction motor systems of the time and introducing AC technology using GTOs (Gate Turn-off Thyristors) and IGBTs (Insulated Gate Bipolar Transistors) to boost efficiency and tractive effort.

This work paved the way for his next projects: adding individual axle control, dynamic weight management and adhesion control systems to locomotives, off-highway vehicles and underground mining vehicles. Kumar was also behind Wabtec’s Trip Optimizer, which now generates trip plans on more than 12,000 locomotives, saving more than 135,000 gallons of diesel fuel per day, cumulatively.

Kumar has spent 21 years developing with a team a locomotive battery system capable of meeting power demands, fitting within existing diesel-electric carbody space and weight-on-rail allotments, and withstanding the harsh railroad environment—ultimately producing Wabtec’s FLXdrive, a 100% battery-powered locomotive that was tested at BNSF in 2021 and is now on order for Union Pacific (10 units); BHP subsidiary Western Australia Iron Ore (two units); Rio Tinto in Western Australia (four units); Australian mining company Roy Hill (one unit); and CN (one unit).

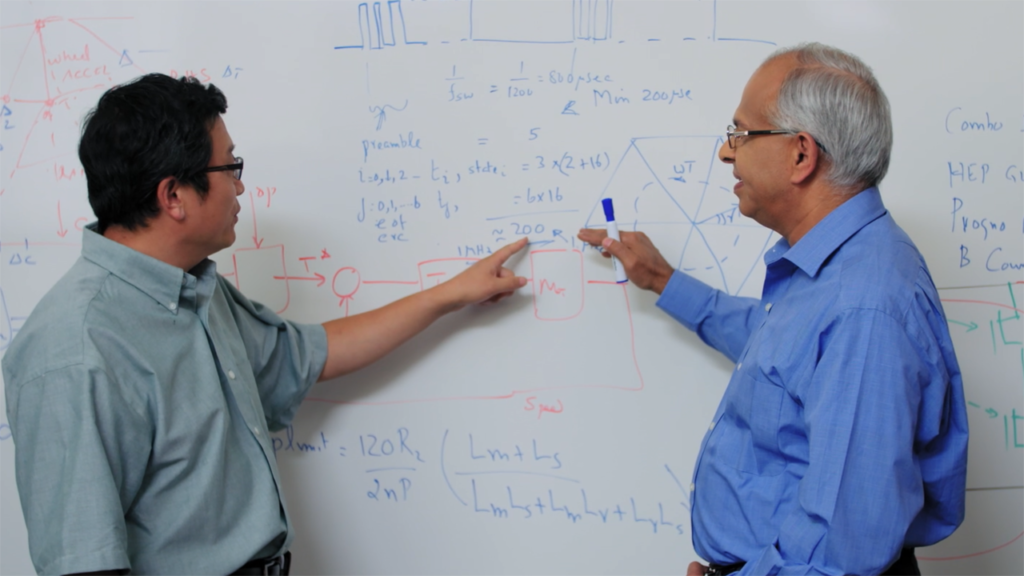

Throughout his working years, Kumar has served as a mentor to employees—including his current manager, Wabtec Vice President of Engineering for Equipment and Services Alan Hamilton, who first sought Kumar’s counsel in 1989 while working on a senior research project for Penn State. Kumar not only enjoys sharing his experience, but also—and more important, he tells Railway Age—listening to and learning from the up-and-coming engineers. Their different perspectives—as well as customer pain-points—provide inspiration for the next product idea or technology.

For Kumar, it’s not about developing technology for technology’s sake, according to Hamilton. The reason Kumar is so effective, Hamilton explains, is that he’s been “innovating with purpose” for his entire career. Technology, for him, has to be something that delivers value, and it has to be safe, has to perform, has to be reliable, and has to be cost-effective and worthwhile for shareholders and others to invest in. For example, when Kumar took GE’s AC drive system technology from the transit space and added it to mining trucks and freight locomotives, “it wasn’t just, OK, now we can propel the train with alternating current traction motors vs. direct current traction motors,” Hamilton says. “It was that you could now have a locomotive with better tractive effort.”

Now, Kumar is working with a Wabtec team on the second-generation FLXdrive, which is slated to have a seven-plus megawatt-hour capacity and to reduce fuel consumption and carbon emissions by up to 30%.

Kumar discusses his career—accomplishments, challenges and most memorable patents—with Railway Age below, in a Q&A:

Railway Age: What prompted you to go into engineering, and railroading?

AJ Kumar: Choosing engineering was really easy. I grew up in India in the ’60s and ’70s, so in those days, the only option was to be a doctor or an engineer—not like here. So you had to choose one or the other. If not, there were no good prospects for advancing. My father is a mathematics professor, my mother is a high school mathematics teacher, and they said I should become an engineer or a doctor—nothing else, no other choice. I like math, so I went into engineering.

RA: You have been with Wabtec (and GE) for many years. What’s kept you there and in the industry?

Kumar: I joined GE in 1977. I graduated from college in India, and then it took me three, four years to get admission to a university here. Rotary International, that’s in Chicago, offered me a full scholarship, so I came to Stanford to study. Back home in India, it’s all power and electric machines, transformers. When I came to Stanford, they’re talking semi-conductors, chips, negative circuits. So I was thinking, what do I do to put those two together? I wrote a letter to GE—not based on any positions open—saying, “These are my qualifications; is there a position I can fill?” Transportation applied. So it’s not just that I wanted to work in transportation; I wanted to work in an industry that I could take the microelectronics, computer science from my studies at Stanford and my previous background of power, machines and transformers, and put them together. Locomotives, transit equipment, mining equipment seemed to be a fit. That’s why I came to GE. It’s just an accident, working in transportation.

Now, what kept me going in transportation is mostly because I worked on almost every new product, anything to do with—not diesel engines, apart from them—but any electrical aspect of any new product, I worked on it from the very beginning. So once the prototypes ran, then something else came up. So for the last 45 years I worked on every new product that came out. That’s kept me going.

RA: What was your first title at GE?

Kumar: I would say engineer, engineer trainee, something like that. So the training assignment, you worked six months in one position, moved to another one, to another one. So the first position I got was in transportation. Diesel engine engineering is where I worked, and I was the only electrical guy in there—no electronics in diesel. I worked to make stand-by power. That was a good experience. I learned aspects of engine control. After three or four assignments, I went to work on electronics and propulsion control.

RA: What has been your greatest accomplishment?

Kumar: It’s a series of two or three things, I would say. The first one was AC single-axle control for locomotives, but it did not come overnight. When I applied to GE in 1977, I wrote that I wanted to work on AC propulsion, AC motor drives. The manager who interviewed me told me there’s no AC motors. So I went asking every year, “Can I work on it? Can I work on it?” Finally, I worked on the transit application for New York City, Washington Metro, Boston, San Francisco Trolley, Los Angeles—AC propulsion for transit applications. But the maturity of electronic components available at the rating we’d need for freight locomotive applications wasn’t there yet. By the late ’80s and ’90s, semi-conductors were available to apply to the railroading industry, so I used my transit experience and converted the DC to the AC, so that was first step, and then individual axle control, which means you can pull more freight reliably. Then the hybrid locomotive came in 1999 or so, as batteries, NiCad (nickel-cadmium) came into existence. We did make one locomotive, a one-axle hybrid, and we ran it up and down in our plant in the 1999, 2000 timeframe. It was feasible because of AC propulsion. The Toyota Prius came out, the NiMH (nickel-metal hydride) battery. So many technologies came out in batteries. Now, it’s Li-ion (lithium-ion). All of them were possible for use in locomotives because of two things: individual axle control and AC technology. In late 2006, early 2007, the hybrid locomotive work stopped because batteries were too expensive, but a byproduct of it was Trip Optimizer. We had been looking at it. With a battery locomotive, a hybrid locomotive, you need to know when to charge and when to discharge, which means you need to know what’s coming ahead of you. And that became Trip Optimizer. (Editor’s Note: Trip Optimizer acts like “cruise control” for trains, generating trip plans based on individual train makeup—number of cars, amount of load, etc.—and railroad conditions in an aim to minimize fuel and emissions while maintaining train handling.) So if you look at Trip Optimizer—now it saves about 135,000 gallons of fuel a day, more than half a billion gallons a year—it came from hybrid locomotives. So it’s a succession of AC technology, which led to battery and hybrid locomotives to Trip Optimizer, and now to battery-only locomotives. So it’s not one accomplishment. It’s all connected.

RA: What has been your greatest challenge?

Kumar: The greatest challenge is, typically, to figure out how to sell an idea to the management, and to be able to explain how it is practical. A lot of things are possible or feasible, but to make money on them, that is where the problem is. The technology is there, but you have to make money. So the greatest challenge to me is coming up with a practical solution. It’s not the technology; the technology is the easy part.

RA: What has surprised you most in your career?

Kumar: The slow speed of adoption. To some extent, since railroading is a 175-plus year-old industry, it’s not easy to change. There’s so much equipment that needs to be converted. So what’s surprised me is the slow change, but I understand why now. It’s not like a greenfield approach—like I want to convert to all-electric locomotives. That’s not practical. Change may also be slow, because there isn’t a national mission for it.

RA: Can you talk about your mentoring role at Wabtec and GE?

Kumar: Since I’ve worked on every new technology and I’ve worked for many years, I have a lot of background from every aspect. So I have helped almost every new engineer who comes along in one way or the other. I supervised their course in engineering at GE, where we had a training program. That’s how I got involved in mentoring. Nowadays, I spend a lot of time with all the young engineers in India and the U.S. I enjoy doing that because of two things: One, I can tell them what I know, but more important than that, they have a completely different perspective, and I learn from them as well. It’s not a one-way street at all. It’s a two-way street, always, and it’s surprising how much they know also.

The reason I came to the U.S. is because of the Rotary International scholarship, so I also spend time with the Rotary Club organization, the students, the exchange students, and work in the community to help them.

RA: You have inspired many at Wabtec and GE. Who inspired you?

Kumar: A couple of my mentors, like Ron Bailey at GE and outside the company like Bill McMurray (a pioneer in the power electronics field, who held 23 patents and was known for the invention of the McMurray-Bedford inverter—Editor’s Note). Also, Tom Lipo (a pioneer in the fields of electrical machines, power electronics and machine drives, and whose 50-year career spanned nearly the complete history of modern solid-state adjustable-speed motor drives—Editor’s Note). They are all experts in their own power electronics industry, and they showed how things could be done, even without a calculator or a computer. Even without all of those things, they used to design things. It is the background they have; it was their intuition that this is how it should be done. That’s what inspired me. A lot of times, you don’t need too many calculators; you can make a guess. And typically it will work out very close to what the optimal solution is.

RA: Where do your ideas come from?

Kumar: Most of the time, ideas come from business meetings. You hear what the customers’ problems are, and almost invariably, fuel is the chief problem, because that’s where they spend most of their money, and also the number of people it takes to move a train. So where the expenses are, that’s where the opportunities are. That’s number one. The second part is the technology—what technology is available out there. So if you know what the problems are and what solutions are available, you can look around for an idea. Automation in new cars, for example, LiDAR, you name it, they can all be applied to the railroad industry. So that’s what I look for. In every information meeting, I look at what problems they are talking about. And as I said, the new engineers, they talk about new technologies. So I bring both of those together. But a lot of things I have brought together haven’t gone anywhere. It’s not like every one of them has gone somewhere. There have been many failures.

RA: Was there one failure that you found most disheartening?

Kumar: If I had to pick one that didn’t work, it was the hybrid locomotive from 1999-2000, but out of that came the Trip Optimizer, a win. I also had a concept 10 years ago for a broken rail detector, but it didn’t take off as a product. Failures occur when maybe the technology isn’t ready yet, the cost is too much. There are many like that.

RA: You have surpassed George Westinghouse on the number of patents earned. What did you think when you heard that?

Kumar: I knew it was coming, but I didn’t think I’d ever get to even hundreds of patents.

RA: What was your first patent?

Kumar: The first one I filed, GE didn’t even apply for it because, maybe for commercial reasons, but it was for a flywheel-powered bus for New York City. (Editor’s Note: This was an electric bus that used flywheel energy storage, not overhead wires like a trolleybus.) But it didn’t take off. We made a prototype. The thinking was, when the passengers get in and out, you spin a flywheel, and the bus has enough range to go four or five miles or so. And in New York City, there is a stop every quarter of a mile. So in 10-15 seconds you spin it up, then you can go four to five miles. It has no engine, no trolley wires, none of those things. That was the first one. But the first patent I got was for improving the power factor of an electric locomotive for Mexico.

RA: At Wabtec, they affectionately call you “the father of AC locomotive technology.” Tell me about how you got there.

Kumar: That may be to some extent a misnomer. Within GE Transportation, and perhaps the U.S., I pushed it quite a bit, but AC motors and AC propulsion existed way, way before. Within GE Transportation, probably I pushed for 20-30 years to make it happen. Once it was implemented, the way it was done, it became, at least within the U.S., a standard. Probably 15% or more locomotives now in service are GE Transportation individual-axle-control units. It became a standard because it has individual axle-control, is air-cooled, and has high reliability and efficiency.

RA: What patent was the most special or memorable to you?

Kumar: The most special was for a Chicago Transit Authority car. They are CAM-operated, very old technology. We put computers in, and with the very first computers, we needed a position sensor, so I put in a sensor with two positions to control the CAM. It’s ingenious, kind of, but it didn’t go too far. The next patent that was practical was the ES44C4 locomotive. (The ES44C4 was introduced in 2009 as part of GE’s Evolution series—Editor’s Note). It is used on BNSF to replace a DC locomotive. DC locomotives are six powered axles, six traction motors, and you can replace that with four AC-powered axles, four traction motors. The center axles don’t have traction motors. When you need more adhesion, you compress a spring and move the weight to the other axles. So there are about 1,500 locomotives running around of that kind. That was the end of the DC motors for GE, because we converted the DC application to four AC motors. The weight-shift mechanism and its control was a simple but elegant solution to a problem.

RA: From DC to AC and now the FLXdrive battery locomotive: What’s next?

Kumar: The E-turbo, for example. I am looking at any waste heat—waste meaning we are throwing it out—like from dynamic braking or diesel engine exhaust. We have concepts to capture that energy and use it. Or maybe, if you look at the railroads and their ESG (environmental, social and governance) commitments. They have big goals to reduce carbon. So it’s possible to use hydrogen fuel cells, for example. All require the conversion of different sources of power for the traction motors. Those are areas of advancement I see in five to 10 years.

Technology is going at such a fast rate. To me, there are a lot more innovations to come—at probably a higher rate than I have seen. Drone technology is one, computer automation is one, all the automation equipment in the new cars, which are almost self-driving. Any one of those could be optimized. That’s what I see.

RA: It doesn’t sound like you’ll be slowing down or considering retirement.

Kumar: As long as there’s interesting work, why should I? The battery-electric locomotive is going to continue for many years. It still may not be completely economical just on fuel savings alone; the battery price has to come down quite a bit. What saves it, potentially, is all the automobile guys are spending billions and billions on batteries, so once most people slowly convert to electric cars, then the technology will be economically feasible. But you cannot wait until then and say, “OK, let me start working on the technology.” We have to keep working on it. It will take five, 10 years to get to that stage. So the battery-electric locomotive could have a good future.

Editor’s Note: Wabtec told Railway Age that “advances in battery capacity, reduced costs and improved computing capabilities make it the right time to apply the technology to rail. Lithium-ion battery pack prices, which were above $1,100 per kilowatt-hour in 2010, have fallen 89% in real terms to $137/kWh in 2020. By 2023, average prices will be close to $100/kWh, according to the latest forecast from research company BloombergNEF.”

Wabtec’s relationship with Railway Age goes back more than 150 years. George Westinghouse (1846-1914), among whose signature inventions was the automatic air brake, actually introduced his revolutionary device publicly in the magazine, having brought a model of it to our Chicago offices in 1869. He obtained a patent for it in 1873. In 1886, Railway Age was the first technical publication to use color on advertising pages, for the Westinghouse Air Brake Company.