MxV Rail R&D: Looking at Locomotives With LUTIS

Written by Matthew Witte, Ph.D., Scientist, MxV Rail

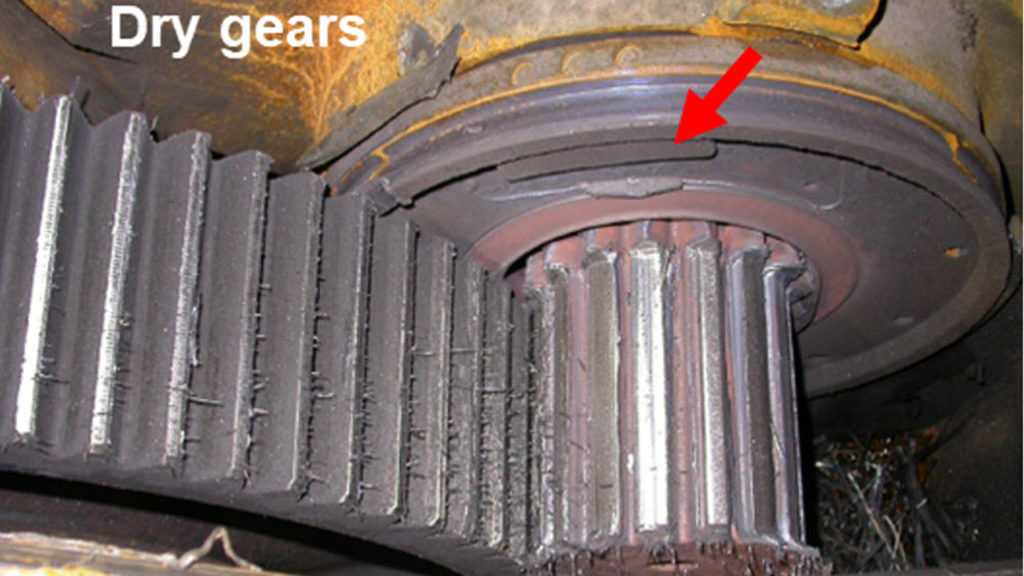

FIGURE 1. Example of traction motor components that failed from overheating. (Courtesy of MxV Rail)

RAILWAY AGE, NOVEMBER 2022 ISSUE: Traction Motor (TM) lockup in a locomotive can be disruptive to a railway’s operations. While modern locomotives are equipped with many onboard diagnostic sensors to provide condition feedback, high-load mechanical components such as the gear train often remain unmonitored.

A gearbox can overheat and lock up (Figure 1, above; and Figure 2, below) and never be detected by the onboard systems, or by any existing wayside detectors. Therefore, wayside detectors that can monitor and indicate the main driveline components prior to failure are desired.

Under the Association of American Railroads’ Strategic Research Initiatives program, MxV Rail (formerly TTCI) coordinated a yearlong, in-service assessment of locomotive undercarriage thermal inspection systems (LUTIS), also known as “in-track thermal detectors.” The thermal detectors, from two different vendors, were early test systems produced for this test. The sensors resided between the rails for monitoring traction motor components; each was configured to monitor the traction motors in real time as the trains passed overhead. The in-service testing of these systems started in late June 2020 and continued until the end of July 2021. The test location, a dual-track main line in the southwestern U.S. (Figure 3, below), provided high-traffic volumes and line speeds for evaluating these thermal inspection systems.

As part of the evaluation, MxV Rail installed thermocouples (TC) and data loggers on three locomotives to record the real-time temperatures of select components. Three specific styles of locomotives were instrumented, including AC and DC traction motors from two different locomotive builders. The TC locations on the TMs were selected to be visible to the thermal scanning hardware. There were eight TC locations per TM on all six TMs of each locomotive for a total of 48 channels per locomotive. The TC data continually produced traces of component operating temperatures as the locomotives traversed the network. This continuous data was useful for determining warmup profiles and normal operating range temperatures for the various components. When the locomotives passed the test site, direct point-by-point temperature comparisons could be made between the TC data and the thermal scanner readouts.

The revenue service trials of the in-track LUTIS demonstrated good correlation between the scanned and onboard temperature measurements. MxV Rail found typical overall differences of approximately two degrees between the two LUTIS units themselves and differences averaged approximately six degrees between the thermocouples and either of the in-track units. Considering inherent differences of each measurement system (thermal scan technology, resolution, precise location of the thermocouples vs. scan position) and the range of operating temperatures, these differences are small. When compared to temperatures associated with an impending component failure, the differences appear to be insignificant.

The suppliers have been working on trending and identification algorithms to indicate abnormal temperature readings and trends. Early deployment of more than a dozen units in revenue service has resulted in more than 120 indications in the first year. To date, every alert has revealed a valid cause for attention. Locomotive undercarriage thermal scanning may eventually make TM lockup an issue of the past. Detailed results of the tests can be found in two Technology Digest publications:

- Poudel, A., M. Witte, and E. Satre. 2022. Revenue Service Evaluation of In-Track Locomotive Undercarriage Thermal Inspection Systems (LUTIS). Technology Digest TD22-008. AAR/ MxV Rail. Pueblo, Colo.

- Poudel, A., R. Alishio, and M. Witte. 2022. On-Board Thermocouple Analysis for Locomotive Traction Motors. Technology Digest TD22-009. AAR/ MxV Rail. Pueblo, Colo.