FreightCar America’s Jim Meyer: ‘We’re the Right Size for Who We Are and Where the Industry Is at This Moment’

Written by William C. Vantuono, Editor-in-Chief

Railway Age Editor-in-Chief William C. Vantuono and Financial Editor David Nahass recently spoke with FreightCar America, Inc. President and CEO Jim Meyer about the efforts to turn the historic, 120-year-old company around by consolidating manufacturing in Mexico and positioning it to meet the needs of the market.

Meyer came to FCA with extensive experience in vehicle manufacturing at multinational companies. Prior to joining FreightCar America in 2017, he was Chairman of the Board at Commercial Specialty Truck Holdings, LLC, a commercial truck manufacturer. Prior to that, he served as Chief Operating Officer of REV Group, the largest manufacturer of specialty vehicles in North America with presence in the fire and emergency, commercial and recreation markets. Meyer also held leadership positions at Brunswick Corporation, Ford Motor Company and Mazda Motor Corporation. His assignments have taken him to Europe, Japan, and North America.

WILLIAM C. VANTUONO: FreightCar America has a storied history. It’s been around for many, many years. But it’s changed and evolved over the years, and it’s run into some problems. What are the changes you’re making?

JIM MEYER: The first thing to understand is the nature of the more recent problems. And when you say storied, that’s what we used to say about Ford Motor Company, when Ford was struggling. Obviously, Freightcar America has this incredible century-long legacy in coal cars. And from a businessperson’s interest, it’s actually pretty remarkable to take something as commodity in nature as a coal car, and still be able to absolutely own the market with it, which they did, for literally a century. Obviously it had ups and downs during that century, but in spite of that there was something it was really doing right. But as we all know, times change; coal car demands are no more. So what the company tried to do was diversify its product offering. And it sounds simple, but it’s not. Engineered on paper, that’s really the simple part. And all that work, fundamentally, got done, reasonably well. It’s a second thing and a significant step harder to put it into production, and do so in a way that you can actually build a business around it. The third piece of it is gaining customer acceptance or market traction. And if you do the first two right, usually the third takes place; it just takes longer. At the same time, they ended up moving into the Shoals facility in Alabama. That really was the crux of the problem in several respects. The first and most obvious: The facility is just too large for the size company we are, in all, but the very best of times—which means that it’s too big, most of the time. That’s the obvious part of what was, in hindsight, a good idea.

WCV: The Muscle Shoals (Ala.) facility was a linear production line.

JM: Yes. In theory, that footprint could probably produce up 10,000 real cars a year. That’s not the size company that we are. And some would argue you could probably do more than that. If you’re from the auto industry, you would be very comfortable in that facility because it’s very straight. It’s got a start and a finish, and a lot of automation and jigs and fixtures and tooling and so forth. It looks like a great big fancy plant—very out of place frankly, in our industry. The door-to-door was nearly a mile long under one roof. And if you’re a production manager in charge of a line, and you can’t even see what’s going on a mile away, that’s hard to manage. When you’re in automotive or other more highly automated industries, that’s one thing. But when you’re not and you’re in a people business, it’s entirely different.

On paper, it was designed to be efficient. But pragmatically speaking, it looks very, very different from any other railcar plant you’ve likely seen. And there’s a reason the others look the way they do. Where we’re building boxcars right now at our new Castaños (Moncolva, Coahuila, Mexico) plant, we’re down to a linear length of factory that is literally one-sixth of what we were occupying at Muscle Shoals. Think about this: You’ve got roughly a sixth of the station numbers that you’re building in, which means you have to pause or move your pieces of WIP (work in process)—railcars moving through the factory in a semi completed state—only one-sixth of the time. Think about how much time is lost when everybody has to stop what they’re doing, everybody has to be done at the same time, or you have to wait till the last station is ready. Everybody puts their tools down. Then you go through the process of manually moving very large pieces of WIP. And if you have to do that 18 times vs. three or four, you save a whole lot of time.

WCV: Railcar production, whether it’s freight or passenger, is not highly automated.

JM: That takes me to the second issue where we ran into trouble. Muscle Shoals was a greenfield factory, essentially in the middle of nowhere. To ramp that place up with 1,000 to 1,500 workers in an area that could barely support that level of new jobs is tough. Think about what was really going on at that moment in time: a new factory with more than 1,000 new workers, many of whom had never been up close to a railcar in their life. And now you’re bringing in all these new models. They’re not even car types for which we have a whole lot of history. So a new model is being launched at a new factory with new people. That was the problem. That was too hard of an undertaking. It’d be too hard of an undertaking for anybody in any industry.

Where we do play best as a business is what we call a pure play manufacturer.We’re not big in the leasing business; we’re not going to have a major lease portfolio anytime soon. We’re going to be a manufacturer, and we’re going to partner with all those leasing companies and others that want to buy railcars from someone who’s not in leasing. But because we’re going to be a manufacturer and a manufacturer only, we better be damn good at it. So, there’s been a lot of dialogue out there about the move to Mexico and the wage differential and yes, the wage differential is very real, and it’s very helpful. But the biggest thing that was accomplished in our move to Mexico is, unlike Muscle Shoals, where we built a factory and then expected the workforce to somehow naturally gravitate toward it, we’re took our business to where the workforce already is: Monclova, Mexico, the heart of railcar manufacturing for North America.

TrinityRail has a big operation near where we are. So does Greenbrier. There is railcar expertise, probably, in every other person walking around the town. It is a railcar manufacturing town. And so, by moving our business down there, we accomplished so many things. Number one, we rightsized our footprint, our fixed cost structure. We staffed up with an extraordinarily experienced workforce. I wouldn’t be surprised if our average employee has 15 or more years of railcar manufacturing experience—the senior people more than that. We acquired the talent we need to be the best manufacturers in the business. And then of course, we even the playing field, so to speak, with respect to the labor differential, because that’s where a lot of railcars get built these days. Our fundamental strategy is really simple: Focus on one thing, manufacturing, and be the absolute best at it, for quality and on time performance, and then have the best underlying cost structure.

WCV: What car types are you building at Castaños?

JM: We designed the plant to build everything we were building in Muscle Shoals and Roanoke and Danville before that. We’ve added to the portfolio, and we haven’t taken anything away from it. We’ve added a 5,450 grain car and a 6,250 plastic pellet car. We refreshed our intermodal well car. We designed the plant to be able to participate fundamentally in all the different car types. And it’s not just about having the right physical structure. It’s about having the right tooling inside so that it’s flexible to the point where you’re not dealing with costly changeovers. We’ve been in business in Castanos for only about nine months, and we’ve executed model changeovers in just a couple of days, in some cases.

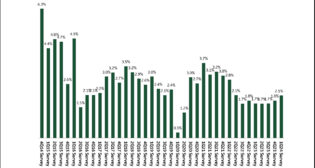

DAVID NAHASS: We are, in general, an industry that is filled with overcapacity. Coming out of automotive, you certainly have context for that. How do you defend against the statement that we’re an industry that, even before you made the move to Mexico, could build 80,000 cars or 90,000 cars? I guess we maxed out at the end. And we probably don’t need more than 40,000 to 50,000 as replacements for an aging fleet. How do you defend the expansion of production capacity in North America, for an industry that would theoretically be considered already in over-supply?

JM: There has been too much capacity in the industry, for too long. If you wind the clock back in our case, 36 months, we had three plants in the United States—Danville, Roanoke and Muscle Shoals. In theory that was probably good for 12,000-plus cars a year. We got rid of all that. We have rightsized our business, in terms of how we view it going forward. We view the current challenges of what has been a very deep rail industry downturn, with the combined effects of COVID. Today, we have a grand total of two production lines. And I’ve shared this any number of times with our shareholders: When you’re in a recession as deep as we’ve been, the last thing you want is a lot of cost and empty stuff you have to pay for.

We got rid of, literally, all of the fixed costs and built an expandable plant in Mexico, which again, today is just two production lines, and in approximate round numbers could support 1,000 cars of production per line. So 2,000 cars, you could say, is fundamentally our capacity at the moment, on one shift, which is absolutely the right number while you’re in the middle of a pandemic and an industry downturn. We were a business that, as recently as 24 months ago, needed approximately 6,000 units of production to break even. Today, we need 2,000. So, we’re the right size for who we are and where the industry is at this moment.

For the expandable part of what we built down in Mexico, we have the two production lines, but in addition to that, we have a paint shop sized to support more than two production lines. We put the basic infrastructure in place to accommodate a bigger footprint. We designed ourselves in a way that we can add incremental production lines as our business emerges, as the industry emerges, and certainly as we hopefully leave COVID behind. Bottom line, we’ve changed from being a fixed-cost-intensive business, which this industry is, to being much more of a variable-cost-based business for now. And again, one that we will scale as things come back. So, we absolutely did the right thing for our business in terms of how we reduced our footprint, our capacity, and provided the flexibility to grow it. I guess you could say we did our part for the industry.

DN: The Mexican market overall has been a very attractive environment for railcar manufacturers and has helped to improve margins. You’re employing the right level of expertise at the facility. Do you feel like you can be competitive with the deliverability vs. the teams and the processes that have been in place for a number of years? In other words, are you able to capitalize on mistakes that had been made by others in their endeavors in Mexico to improve on the deliverability by FreightCar America for production coming out of Mexico?

JM: I’ve worked in manufacturing my entire 35-year career, and I could not be happier by the flawlessness at which this new facility came on line. There were probably 10 things that had to get done perfectly for us to be where we are today. All 10 things were done perfectly. Three years ago, where we are today in Castaños was piece of desert. And last July, while we were still very much under construction, we started receiving our first material. We had our first car off the line in August. We received our AAR certifications in record time in October, which speaks to the quality and robustness of the processes employed. To my knowledge, no one has ever gotten AAR-certified in anywhere near that period of time. And we were delivering cars to the customer starting in November. The quality coming out of the factory is exactly where we hoped it would get to. It was there from the start. You probably wouldn’t expect to hear someone like me saying it differently, but our customers that have now taken product out of Castaños will echo the same thing. We hired when the rest of the industry was in a downturn, so there was a lot of talent on the street. Our goal is to be the place where everybody in the business wants to work, so we can retain this important talent.

WCV: Have you run into any issues sourcing components?

JM: Fundamentally, no. But in a very macro sense, the entire North American supply base is under a great deal of stress now, not specific to rail but in general. On top of that, the world is experiencing unprecedented pricing and supply constraints on steel. Managing steel is an everyday job for a whole bunch of people these days. I view the move to Mexico, from a supply base standpoint, as helpful. We do have a large mill in Monclova. There’s a whole new universe of suppliers in Mexico that we didn’t have exposure to, and/or a real sensible way to work with in the past that we have now. One of the many pluses of being where we are now will turn out to be the supply base. We knew, going in, it would be from a skill standpoint with the mill down the street I think it’s going to prove a lot bigger than that. Supply everywhere is something not to be taken lightly right now.

WCV: Much of rail traffic growth is really in the intermodal space, so a lot of it is consumer-driven. Where do you see FreightCar America, going forward?

JM: It’s one level of definition to say, “Well, we’re going to be the pure-play manufacturer. We’re not going to compete with all the leasing companies out there. We’re going to be the best possible supplier to them.” That’s important. But when you think about it in terms of the bigger picture, you’ve got the two really big companies, Trinity and Greenbrier. And then way, way down, you’ve got the smaller companies that do very low volume, like dozens at a time of specialty car production. The companies like Ebenezer Railcar Services. There’s a massive amount of market space in between those two bookends. That’s where FreightCar America is going to play. We’re not trying to grow to be the size of Trinity or Greenbrier. That’s not the focus.

Where will we compete? Where will we win? In addition to not having any conflicting interest with the leasing customers out there, we have got by all accounts the best engineering department in the industry. We have a massive amount of investment in flexible tooling. Now that we’ve got the proper size and cost in Mexico, we are really well-positioned for smaller- to medium-sized production runs. We absolutely want the 1,000- and 2,000-unit borders that are out there, but we don’t need them to live. We can get really happy customers that want a particular set of changes and modifications to a relatively modest-sized production run. We’ve got the engineering talent, the tooling in place, and the cost structure that lets us be efficient at it now. We can be really happy as a business on the smaller production runs, regardless of car type.

The best example of that is probably in the conversion space. You hear us talk about that a fair bit, for converting coal cars. We were the natural go-to company because we built 80% of the coal cars, the first time around. And during the past 20, 25 years of converting cars, we’ve gotten really good at it. There is still a lot of the coal car fleet out there that is unproductive, but with a useful life. On top of that, you also had a large ramp-up in the sand car fleet., which is now also highly underutilized. Today, within our conversion business, a large part of what we do is converting sand cars. That really exemplifies a company in the middle space, with strong engineering, focused purely on manufacturing, where we’re good and where we can win.We have a portfolio of approximately a dozen different car type configurations that we can convert—for instance, our old BethGon cars. It’s not nearly as restrictive as one might imagine. It’s good economics. If it wasn’t, there wouldn’t be a marketplace for it.

DN: You spoke very eloquently about quality, which is a huge concern to anybody buying railcars, because they are such long-lived assets. Historically, when FreightCar made a transition into alternate car types, there’s been some resistance. It takes a little while to break through on market share. How do you go through the process of explaining to what is a fairly sophisticated, yet somewhat resolute, marketplace about its knowledge, in terms of what they think is right and wrong? How do you re-educate that marketplace about FreightCar America’s new offerings coming out of this facility? And how that flexibility and the modernity of the facility add value and improve on quality as a deliverable concept to your customer base?

JM: The first two things we talk about every day are safety and quality. Every day, those are the first two reports I read. We are laser-focused on both. Those two things track incredibly well. Safety is a little easier to measure on an external basis, with OSHA data. We run as safe a business as possible per OSHA. We’re in the 99th percentile for safety in heavy equipment manufacturing. That’s the one tangential piece of data where we can measure ourselves, very objectively, with competitors.

On the quality piece, rail is a very conservative industry. We have, like everybody else, our quality systems. We have our customer inspectors on site signing off on cars. So we’re getting our day-to-day quality feedback, just like the other builders. Our customer feedback has been very strong. We’re over the hump of getting people comfortable with building our portfolio. The first thing is education. Most of the car types we’re building, while new to us 20 years ago, tare not new to us now. We’re on our second-generation intermodal well car, for example. So for the most part, again, we’re entering or building a refined product, to the degree that it has been redesigned for manufacturing—better processing and material cost efficiency, or utilization. So it’s not really sexy new product development. It’s a lot of product, tooling and processing refinement.

There are car types where we don’t have as much experience and/or a name for ourselves. We’d love to be bigger right now in the plastic pellet business. We’ve got the car, we’ve got the lining capability. But we don’t yet have the marketplace, the widespread acknowledgement that we’re in it, like we do our other car types. Some of this just takes time and persistence, and we will get there. But the good thing about our business and how we redesigned it is that we don’t need things that we haven’t done before to make our business successful. We like where this business is going, and what we expected to produce from a business standpoint. We can do that without tank cars, without having the high level of volumes we’ve had in the past. We’ve built robustness into our business. So that’s a long way of saying, and just very truthfully, some of this does take time. But it’s no longer stuff that’s quite on the same critical path that it would have been under our old cost structure.