Freight RAILCAR Act Introduced

Written by William C. Vantuono, Editor-in-Chief

Democrat Brad Schneider (left) and Republican Darin La Hood teamed with four other Congressman to introduce H.R. 8082.

Six U.S. Representatives—three Democrats and three Republicans—have introduced bipartisan legislation enabling a tax credit for freight railcar owners purchasing new or refurbishing existing equipment that “will incentivize investment in safer, greener freight railcar manufacturing in the United States.” The legislation, H.R. 8082, is the “Freight Rail Assistance and Investment to Launch Coronavirus-era Activity and Recovery (RAILCAR) Act.”

H.R. 8082’s sponsors are Reps. Brad Schneider (D-Ill.) and Darin LaHood (R-Ill.) Schneider and LaHood were joined by Reps. Dan Lipinski (D-Ill.) and Rick Crawford (R-Ark.), Chairman and Ranking Member, respectively, of the House Transportation & Infrastructure Committee Subcommittee on Rail, and by Reps. Earl Blumenauer (D-Ore.), and Drew Ferguson (R-Ga.), both members of the House Ways & Means Committee.

H.R. 8082 offers freight railcar owners a time-limited 50% tax credit for purchasing new freight railcars or refurbishing existing freight railcars that result in improving capacity or fuel by at least 8%, according to the Railway Supply Institute, which worked with the bill’s sponsors and railcar builders and owners to craft the legislation. It also provides separate tax credits for scrapping railcars based on their depreciated value and for capital expenditures on equipment or technology enhancements that improve environmental standards or the safety, quality, or efficiency of railcar manufacturing and repair operations.

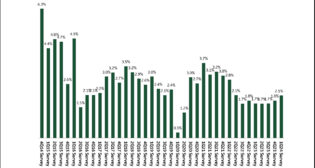

“This credit is intended to encourage freight railcar owners to modernize their fleet to better meet Precision Scheduled Railroading standards, accelerate the industry’s production of new tank cars to meet improved safety standards, and to increase the efficiency of the fleet by utilizing more energy-efficient freight railcars,” RSI noted. “This legislation comes as demand for new freight railcars recently hit near-record lows on par with the levels of the [2008-2009] Great Recession.”

Key Provisions

H.R. 8082 provides a time-limited 50% tax credit expiring Dec. 31, 2024 for new railcars or modification of existing railcars to help offset the costs associated with either of the following:

- Replacing two existing railcars with a new railcar that improves fuel efficiency or capacity by at least 8%.

- Refurbishing or modernizing an existing railcar to improve fuel efficiency or capacity by at least 8% or to upgrade to DOT-117 tank car specifications.

The bill also provides a separate tax credit (also expiring Dec. 31, 2024) available for the scrapping of a railcar based on the depreciated value of that particular asset. On top of that, it provides a time-limited 50% tax credit, expiring one year earlier on Dec. 31, 2023, for capital expenditures on equipment or technology enhancements in railcar-related manufacturing or repair shops if that equipment improves the implementation of enhanced controls to meet environmental standards including emissions limits under the Clean Air Act, or improves the efficiency, quality, or safety of railcar or railcar component manufacturing, repair, and modernization operations.

To benefit from the new-build tax credit, railcars being replaced must have been in service during the 48 months prior to enactment of the bill and must be permanently taken out of service. Anyone utilizing the credit tied to the scrapping of a railcar cannot also use that car for purposes of meeting eligibility requirements for the new-build tax credit. Facilities eligible to build or refurbish railcars must be privately or publicly owned and may not be under the control of a state-owned or state-supported entity.

RSI cited environmental benefits that could result from H.R. 8082. As examples, over a 20-year period, an 18.9% capacity increase in covered hoppers will result in 6.8 million fewer tons of CO2 (carbon dioxide). A 16.7% capacity increase in double-stack intermodal cars will result in 3.3 million tons of CO2 saved. A 20.5% capacity increase in autoracks will result in 13.2 million tons of CO2 saved.

“The Freight RAILCAR Act will help incentivize private investment in the freight railcar manufacturing industry to preserve thousands of American jobs, reduce our carbon footprint and ensure the integrity of our critical rail supply chains,” said RSI Senior Vice President Government and Public Affairs Nicole Brewin. “Railway suppliers are facing increasingly difficult economic circumstances as a result of the COVID-19 pandemic and many have been forced to significantly reduce their manufacturing workforces. We thank representatives Schneider, LaHood, Lipinski, Crawford, Blumenauer, and Ferguson for introducing this bill to help restore and maintain the tens of thousands of jobs that depend on this industry and urge Congress to advance this legislation quickly to help railway suppliers cope with the economic fallout of this pandemic.”

RSI noted that prior to the start of the COVID-19 pandemic, the freight railcar manufacturing industry directly supported 65,000 U.S. jobs in all 50 states, with average salaries exceeding the national average by 40%. “Including the Freight RAILCAR Act in a future infrastructure recovery package will protect and preserve 65,000 American manufacturing jobs, invest in environmentally efficient railcars and upgrade the fleet, and help the rail supply industry survive the economic impact of the COVID-19 pandemic,” RSI said. “Without immediate action, the loss of rail manufacturing jobs will be felt nationwide at the worst possible time for our country. Impacts will be felt acutely in states like Arkansas, Oregon, Illinois, Louisiana, Pennsylvania, and Texas, where some of the nation’s leading freight railcar manufacturers and suppliers have already reduced their workforces by as much as 50%. Downstream effects will be felt on virtually every sector that supplies the freight railcar industry, from iron and steel manufacturers to factory equipment suppliers. We must ensure the North American freight rail manufacturing base survives this time of uncertainty. We cannot be left dependent on foreign countries for freight railcar production.”

Railway Age Financial Editor David Nahass comments:

“This legislation could be reminiscent of the late-1970s railcar investment tax credit that had non-railroaders—doctors, dentists, for example—buying freight cars. It created an artificially inflated overbuilding period that resulted in the market tanking around 1980-81. What we need to see is an equipment cycle driven by demand, not by tax credits or congestion or poor service. Those never end well.

“The bill will increase the number of older cars being scrapped, but it still won’t address the problems related to depressed loadings, or the need to go after new rail freight business. For example, one statistic posted by RSI on moving to higher-capacity covered hoppers was for a 4,750cf car. If the capacity increase is from a 5,200cf to a 5,400cf, the motivation decreases substantially. My expectation would be that many of shippers using 4,750s right now are using them for a reason beyond price.

“Other than grain hoppers and intermodal cars, most (if not all) general freight cars are at a maximum load weight/size ratio. The only other large exception might be boxcars. However, the marketplace dynamic over boxcar demand and its relationship to capacity and the needs of the shipper community won’t necessarily be improved by this legislation.

“Another interesting thing is whether the fuel emissions part of the legislation is broad enough to incorporate CNG tenders. Additional incentives on that front potentially generate change on an issue directing impacting rail’s competition with the trucking industry”