EMD® Joule Build Under Way Down Under

Written by William C. Vantuono, Editor-in-Chief

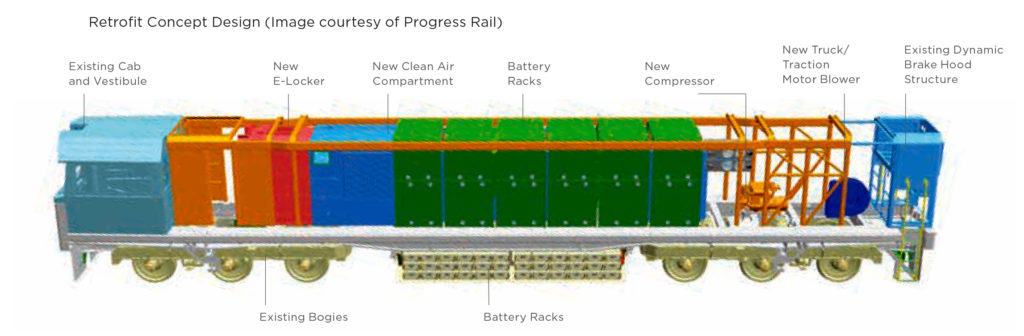

Rendering of an Aurizon BEL. Progress Rail illustration.

Progress Rail, a Caterpillar Company, has begun constructing the BEL, a battery-electric EMD® Joule prototype locomotive for Aurizon, Australia’s largest freight railroad. A rebuild of an existing, Class 4000 GT42CU AC diesel-electric from the early 2000’s manufactured by EDi Rail, Maryborough, under license from Electro-Motive Diesel for use on narrow gauge railways in Queensland, the BEL will be “the first zero-emissions-capable freight locomotive constructed in Australia powered by batteries.”

Zero emissions, Aurizon notes, “will be technically achievable when totally renewable energy sources such as solar and wind are available to charge the locomotive batteries. This does not include associated activities such as loading and unloading and other activities within the haulage supply chain. We have more than 120 of the 4000 Class locos in our national fleet, meaning a successful battery conversion could provide a much faster, less expensive decarbonization pathway, using fully recycled assets. Locomotives typically have an asset life of 20-30 years, so replacing the diesel engine with batteries and recycling the remainder of the locomotive is less expensive, more environmentally sound and based on circular economy principles.”

The prototype BEL, which Progress Rail is building at its Redbank facility in Southeast Queensland, will be based on the EMD® Joule SD40JR, albeit with a higher power rating of 4.5MWh. The unit “will be designed as a heavy-haul freight locomotive, capable of working at locations across Aurizon’s national footprint and suitable for Australia’s harsh operating conditions,” Progress Rail said. The locomotive will employ regenerative braking to assist in battery charging.

Retrofitting a 4000 Class locomotive is targeted at “recycling and re-using existing assets with stored carbon,” Aurizon said. The build involves removing the diesel engine, fuel tank, radiators, alternator, two traction inverters and other components; overhauling and retaining the engineer’s cab, chassis, bogies (trucks) and traction motors; and installing lithium-ion battery packs, the control system, inverters for each axle, and an air compressor.

BEL construction is expected to be complete by early 2025, with operations trials commencing in the first half of 2025. The charging infrastructure on the selected Australian rail corridor will be completed concurrently.

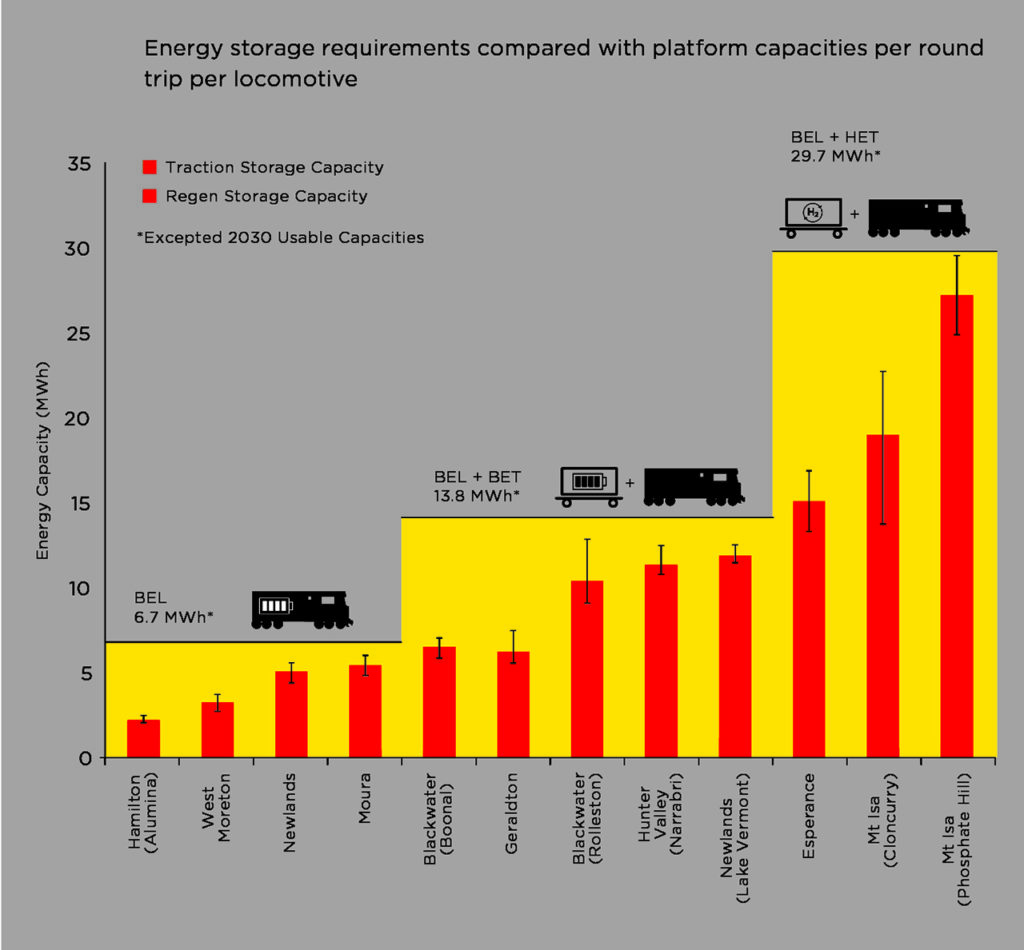

Aurizon noted that “while the BEL will be the platform for our renewable energy fleet, different solutions for different hauls across our national footprint will be required to meet customers needs.” These are:

- Battery-electric locomotive (BEL) for hauls up to 250 miles.

- BEL plus battery-electric tender (BET) for hauls up to 525 miles.

- BEL plus hydrogen-electric fuel cell tender (HET) for hauls of more t6han 525 miles.

Aurizon Managing Director and CEO Andrew Harding said the BEL project “sits at the heart of Aurizon’s decarbonization initiatives with a target of achieving net-zero operational emissions by 2050. Modern freight locomotives using renewable energy sources have the potential to transform the nation’s freight supply chains for customers, communities and the Australian economy. Not only will this dramatically reduce the carbon footprint for our freight transport needs and the community in general, but it will also provide a significant competitive advantage for Australian industries and exporters in global markets. Australia is ideally positioned to supply the world with great reserves of future-facing commodities that will fuel and feed a decarbonizing world for decades to come. This includes commodities such as copper, nickel, rare earths, grain and phosphate. Delivering high-quality Australian products for export across zero or low-carbon supply chains will be a win-win for Australian companies and Australian communities.

“We are excited to support Aurizon in achieving its carbon reduction goals,” commented Progress Rail Senior Vice President Colin Kerelchuk. “This project leverages our worldwide capabilities, while heavily relying on our expert workforce in Australia. We will deliver this EMD® Joule out of our Redbank, Queensland facility, where we have recently secured a long-term lease extension to continue operations through 2034. With a presence in Queensland since 2015, we are well positioned to deliver broad technology and fleetwide modernizations to improve our customers’ operational and emissions efficiencies.”

Aurizon has commissioned the University of Queensland and Central Queensland University to undertake modeling work and research on emerging battery technology, network infrastructure and charging facilities required to provide renewable electricity to the locomotive batteries.

Aurizon annually hauls more than 250 million tons of Australian commodities on its 3,200-mile network, connecting miners, primary producers and industry with international and domestic markets. It provides customers with integrated freight and logistics solutions across an extensive national rail and road network. This includes retail goods and groceries in containerized freight; commodities such as grain, phosphate and critical minerals; and Australian coal and iron ore for export. Among its operations are the Tarcoola to Darwin railway in central Australia that connects with the nation’s closest port to Asia; and the Central Queensland Coal Network, which includes 1,300 miles of electrified corridor that is able to tap into renewable energy sources from the Queensland grid.

Watch this Aurizon video on the BEL: