Intermodal Briefs: GPA, VIP

Written by Marybeth Luczak, Executive Editor

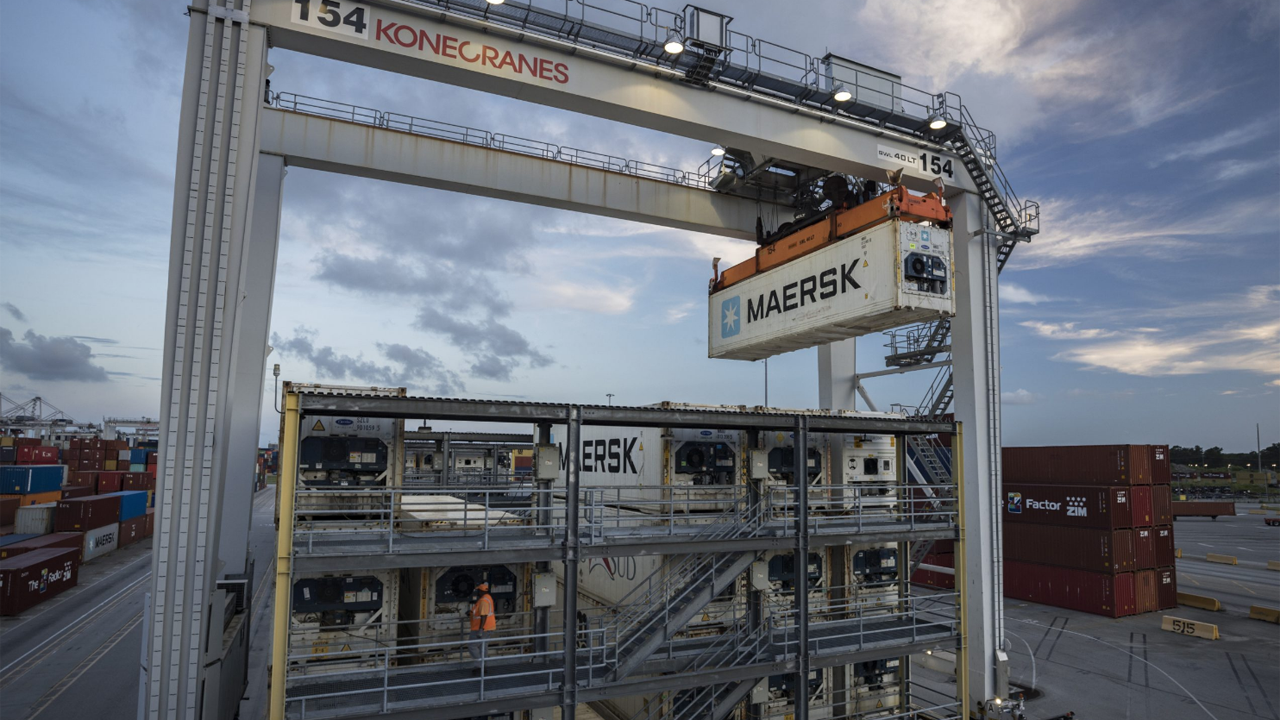

The Georgia Ports Authority will construct seven additional refrigerated container racks at Garden City Terminal in Savannah, for a new total of more than 3,500 plugs. (Georgia Ports Authority / Stephen Morton)

The Georgia Ports Authority (GPA) Board approves construction of seven additional refrigerated container racks at the Port of Savannah to expand capacity. Also, Virginia Inland Port (VIP) is the first of the Port of Virginia’s six general cargo terminals to receive 100% of its electricity from renewable sources.

GPA reported on Jan. 31 that it is increasing chilled cargo capacity at the Port of Savannah with the addition of seven new refrigerated container racks. The goal is to “stay ahead of anticipated growth in demand,” it said, as private chilled and frozen warehouse space in Savannah is slated to grow by 11% in 2023 to more than 2.2 million square feet. The chilled and frozen products handled at the port range from proteins, such as poultry and seafood, to blueberries, avocados, citrus, stone fruits and onions, among other commodities.

The $6.2 million project will grow the number of slots for cold cargo to 3,506 at Garden City Terminal, counting chassis plug-ins. Savannah’s Ocean Terminal provides another 368 refrigerated container plugs.

Additionally, GPA reported that four new STS (ship-to-shore) cranes are expected to arrive at the Port of Savannah on Feb. 9. They are large enough to handle vessels with a capacity of more than 20,000 TEUs (twenty-foot equivalent container units).

“Expansion among our cold storage partners in the Savannah market will drive greater volumes of chilled cargo crossing our docks,” GPA Executive Director Griff Lynch said. “While the Port of Savannah already accommodates the most refrigerated containers on the South Atlantic and Gulf coasts, enhancing our on-terminal capacity will better support the jobs and opportunity sparked by private investment.”

In related developments, GPA announced last month that it handled a record 5.9 million TEUs in Calendar Year 2022, an increase of 5% over 2021.

Helping the Port of Virginia move forward with its goal of reducing emissions and becoming carbon-neutral by 2040, VIP has signed a new agreement with the Rappahannock Electric Cooperative allowing the cooperative to provide “clean electricity” to the inland port terminal from Virginia-based solar installations. According to the Port of Virginia, the “clean energy” began flowing on Jan. 1. VIP is the first of the port’s six general cargo terminals to get 100% of its electricity from renewable sources.

“We have a clearly stated goal of getting away from fossil fuel use and this is another important step forward,” Virginia Port Authority CEO and Executive Director Stephen A. Edwards said.

The Port of Virginia is sourcing some of its electricity for cargo operations at its terminals in the Norfolk Harbor from renewable sources, it said. By 2024, the port reported that it will fulfill all of its electricity needs at its marine terminals from renewable recourses, ahead of the original 2032 “SCOPE 2” deadline. (Scope 2 emissions are indirect greenhouse gas emissions associated with the purchase of electricity, steam, heat or cooling, the port noted.)

The move to renewable energy is part of the overall expansion and modernization of VIP. Work is expected to begin this year on a $15 million capacity expansion, which will allow it to retire straddle carriers and begin using rubber-tire gantry cranes to move containers from railcars to trucks.

“A reconfigured rail operation and container stacking area combined with new cargo conveyance equipment will give us room to grow and drive efficiency in the same space, but with a smaller carbon footprint,” Edwards said. “Nearly six years ago, we began to electrify our operation, audit carbon emissions, replace aging equipment with greener machines and make greater use of technology. As a result, more than one-third of the equipment we use on terminal today is electric and our use of technology is driving efficiency.”

In related developments, construction of five new STS cranes for the Port of Virginia is under way with delivery set for December 2024. Additionally, the port announced last month that it has achieved its “most productive year on record” having processed more than 3.7 million TEUs in 2022, an increase of about 5.1% over 2021.