NS Ohio Derailment Under Investigation; NTSB Preliminary Report Scheduled (Updated Feb. 22)

Written by William C. Vantuono, Editor-in-Chief

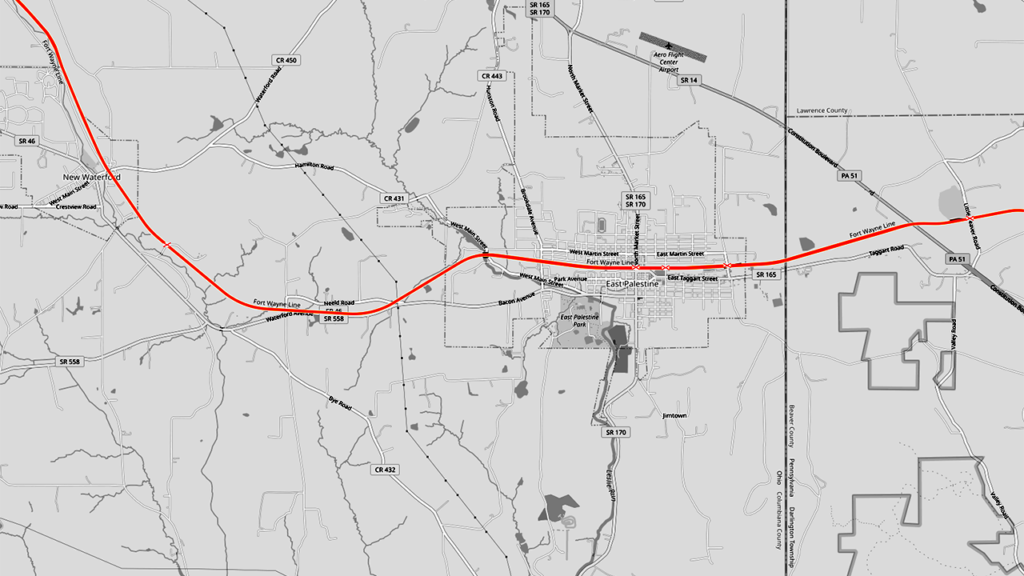

Aerial view of the Norfolk Southern freight train derailment in East Palestine, Ohio captured on Feb. 5. (Source: NTSB)

Fifty cars of Norfolk Southern merchandise train 32N, hauling vinyl chloride and a variety of other freight, derailed in East Palestine, Ohio late on Feb. 3, causing a massive fire that forced evacuation of a three-square-mile area. No injuries to crew, residents or first responders were reported. The cause of the accident, which the National Transportation Safety Board says was mechanically related, remains under investigation. The train was operating from Madison, Ill., to Conway Yard near Pittsburgh, Pa. Service has been fully restored, and NS has established a charitable fund to assist the local community. The NTSB will issue a preliminary report on Feb. 23 at approximately 10:00 AM ET.

In a Feb. 14 Service Advisory, Norfolk Southern said it “is continuing to work with local, state and federal leaders and the community affected by the derailment. Additionally, Norfolk Southern would like to update our customers on the status of railroad operations. Both main lines were restored to service on Feb. 7, after our Engineering team and contractors worked to quickly clear the site and lay down new infrastructure. Norfolk Southern continues to make progress in two key areas: addressing the backlog of traffic; and getting power and crews back in cycle. As we continue to do so, customers will see a positive reflection of these efforts in the status of their shipments.“

NS immediately established a Family Assistance Center to address the needs of the community and support those directly impacted. Additionally, the railroad supported the efforts of the American Red Cross and their temporary community shelters through a $25,000 donation.”

On Feb. 14, NS announced it is creating a $1 million charitable fund “to be available immediately as one component of its planned support for the community of East Palestine, Ohio. The company will work with state and local leaders to identify where the donations can do the most good.”

“We are committed to East Palestine today and in the future,” said NS President and CEO Alan Shaw. ”We will be judged by our actions. We are cleaning up the site in an environmentally responsible way, reimbursing residents affected by the derailment, and working with members of the community to identify what is needed to help East Palestine recover and thrive. This fund allows Norfolk Southern to move quickly to meet their immediate needs. We anticipate making further charitable contributions in East Palestine as conversations continue with local leaders and members of the community.”

NS said the fund “will supplement other efforts to support residents, businesses, and first responders.” These include:

- Distributing more than $1.2 million in financial assistance to nearly 900 families and a number of businesses to cover costs related to the evacuation. Those include reimbursements and cash advancements for lodging, travel, food, clothes, and other related items.

- Reimbursed the East Palestine Fire Department $220,000 to replace Self-Contained Breathing Apparatus (SCBA) air packs, which allow firefighters to breathe compressed air when responding to fires.

- Providing more than 100 air purifiers for residents to use in their homes. Air purifiers are also being purchased for the East Palestine municipal building in coordination with the City Manager.

- Coordinating and funded cleaning and air monitoring services for the East Palestine Elementary and High Schools.

- Completing more than 400 in-home air tests in conjunction with U.S. Environmental Protection Agency. In-home air monitoring has not detected substances related to the incident and does not indicate a health risk.

Derailment Facts and Figures (So Far)

Following the derailment, NS said 20 of the more than 100 cars on the train were classified as carrying hazardous materials. NTSB said 11 pressure tank cars carrying hazardous materials derailed, five of which were carrying vinyl chloride. At a Feb. 5 news conference, the NTSB said a mechanical problem with a railcar axle caused the derailment. NTSB member Michael Graham said the three-member train crew received a detector alert about the mechanical defect “shortly before the derailment,” but said the Board was still working to determine which railcar experienced the problem. He said investigators identified the exact “point of derailment,” but did not disclose the location.

Railway Age learned that the derailment probably occurred due to a combination of factors and unfortunate timing. The train passed a wayside hotbox detector that reported zero defects. Shortly after that, a wheel bearing started to overheat, which in turn caused an axle to severely overheat as the bearing got hotter. This eventually resulted in an axle failure that, unfortunately, occurred within a few moments after the train had passed by a second hotbox detector that flagged the problem, alerting the crew. The engineer immediately applied the brakes, but the axle had already failed, and the train derailed.

On Feb. 14, NTSB issued an update confirming what Railway Age learned:

“On Feb. 3, at approximately 8:54 p.m., local time, eastbound Norfolk Southern Railway, general merchandise freight train 32N, derailed on main track 1 in East Palestine, Ohio. As a result of the derailment, 38 rail cars derailed and a fire ensued that damaged an additional 12 cars. There were 20 total hazardous material cars in the train consist—11 of which derailed. A list of what the derailed rail cars were carrying is available online. There were no reported fatalities or injuries.

“NTSB is conducting a safety investigation to determine the probable cause of the derailment and issue any safety recommendations, if necessary, to prevent future derailments. The NTSB can also issue urgent recommendations at any point during the investigation. All questions regarding the safety investigation should go to NTSB. While emergency response will be a factor in the investigation, NTSB is not involved in air monitoring, testing of water quality, environmental remediation or the evacuation orders. Questions on environmental issues should be referred to the Environmental Protection Agency. Learn more: East Palestine Train Derailment – EPA OSC Response.

“Parties to the NTSB investigation provide technical assistance. They include: U.S. Department of Transportation’s Pipeline and Hazardous Materials Safety Administration and Federal Railroad Administration, Ohio State Highway Patrol, the Village of East Palestine, Norfolk Southern Railway, Trinity Industries Leasing Company, GATX Corporation, Brotherhood of Railway Carmen, International Association of Sheet Metal, Air, Rail and Transportation Workers and Brotherhood of Locomotive Engineers and Trainmen.

“NTSB continues to work with the investigative parties to determine what exactly caused the derailment and to evaluate the emergency response efforts.

“NTSB investigators have identified and examined the railcar that initiated the derailment. Surveillance video from a residence showed what appears to be a wheel bearing in the final stage of overheat failure moments before the derailment. The wheelset from the suspected railcar has been collected as evidence for metallurgical examination. The suspected overheated wheel bearing has been collected and will be examined by engineers from the NTSB Materials Laboratory in Washington, D.C.

“The tank cars are currently being decontaminated. Once the process is complete, NTSB investigators will return to Ohio to complete a thorough examination of the tank cars.

“The vinyl chloride tank car top fittings, including the relief valves, were removed and secured in a locked intermodal container pending an NTSB examination. Once the fittings are examined by NTSB investigators, they will be shipped to Texas for testing, which will be conducted under the direction of the NTSB.

“NTSB has obtained locomotive event recorder data, forward- and inward-facing image recording data and wayside defect detector data. NTSB investigators continue to review documentation, event recorder data and perform interviews. A preliminary report is expected to publish in two weeks.”

As to the hazmat in the derailed cars, on Feb. 5, NS reported that ‘during the monitoring of the derailed cars, it was found that the pressure relief devices on some of the cars had stopped working. If not addressed, it could result in a catastrophic failure of the cars. In coordination among all agencies and stakeholders, we have put together a plan to manually vent the cars. The contents will be drained in a controlled fashion. To protect the environment, we have prepared pits and embankments to drain the material into which will then be remediated. When it is safe to do so, the manual release of the pressure will be via a controlled breach of several rail cars, and under the supervision of experts and first responders. This will be loud and visible. Some of the material will burn off as it drains for a short number of hours. We have been and will continue monitoring air quality with Ohio EPA. Afterward, cleanup work on the site can safely continue.”

The tank cars were vented on Feb. 6.

Vinyl Chloride (VC), also known as chloroethylene, chloroethene, ethylene monochloride and monochloroethane, chemical reference number (CAS) 75-01-4, is a colorless, carcinogenic, highly flammable gas that evaporates quickly. It is transported by rail in pressurized, non-insulated tank cars with thermal protection. It is used to make polyvinyl chloride (PVC) pipes, wire coatings, vehicle upholstery and plastic kitchenware.

“Vinyl Chloride, a hazard division 2.1 flammable gas, can only be transported in DOT specification 105, 112 and 114 tank cars,” note Peter Conlon and Alan Maty of Railway Technology Consulting Associates, LLC. “49 CFR 173.31(b)(4) requires thermal protection for tank cars transporting Class 2 materials. Vinyl chloride therefore would be shipped in tank cars with thermal protection. The cars in the Ohio derailment were 105s, since there are few 112s with thermal protection and few 114s left in service (download NTSB’s derailment list, below).

”Thermal protection consists of a material or system applied to tank cars to limit the transfer of heat to the tank in event of exposure to pool or torch fires. It is intended to reduce the likelihood of tank failure under such conditions. Thermal protection is not the same as insulation, which is intended to maintain or moderate lading temperature under ambient conditions. Per DOT regulations in 49 CFR, a thermal protection system must have sufficient thermal resistance so there will be no release of any lading within a tank car, except through the pressure relief device, when subjected to 1) a pool fire for 100 minutes and/or 2) a torch fire for 30 minutes (AAR Field Guide to Tank Cars, 4th ed.).”

AAR Statement

On Feb. 16, the Association of American Railroads issued the following statement:

“Situational Awareness: On Feb. 3, a Norfolk Southern (NS) train carrying hazardous materials (hazmat) derailed on the of Ohio-Pennsylvania border. In coordination with state and local officials, and under a unified command established by local first responders, nearby residents were evacuated within a one-mile radius of East Palestine, Ohio. Following efforts to contain resulting fire and prevent the spread of shrapnel and debris, a series of controlled releases were executed to release of pressure from the tank cars. A collective decision was made by local, state, and federal officials that this was the safest and best option to protect the surrounding community and minimize environmental impact. Remediation efforts are ongoing in coordination with state and federal environmental agencies, and well as other authorities.

“NS continues to provide direct support to impacted community members and is working to ensuring an environmentally responsible cleanup. The railroad has said it is coordinating with community members to identify additional areas of need.

“Beyond NS, AAR and its members sympathize with those affected. Railroads take their responsibility to move goods critical to the economy safely across the country seriously.

“Allow the Investigation to Proceed: The National Transportation Safety Board (NTSB) is the independent, government agency tasked with investigating the incident. NTSB will be the lead agency providing updates into the investigation. It issued an update on Feb. 14.

“Interested parties should let the investigation proceed. As the NTSB’s work continues, any speculation as to the cause or contributing factors that lead to the incident is just that—speculation—and undermines the overall fact-gathering process. Additionally, immediate pushes for legislative or regulatory action absent of NTSB results and in response to the accident is premature at best—and opportunistic at worst. Interested parties should consider the available facts on rail safety (see below), immediate ‘solutions’ to enhance safety permeating some coverage and the potential motivations of the loudest voices alleging a fundamental failure in U.S. railroading.

“Railroads’ Commitment to Safety: The Associated Press recently reported: ‘The railroad industry is generally regarded as the safest option for most goods and federal data show accidents involving hazardous materials are exceedingly rare.” USA Today noted in a separate report: ‘Not only was [the Feb. 3] incident relatively rare, so too are deaths from incidents involving hazmat cargo railcars. The last reported death from a hazardous material on a [U.S.freight] train was in 2011.’

“Overall, railroads are safe. While 99.9% of all hazmat shipments reach their destination without impact, the less-than 0.1% have the potential to dramatically impact the communities served. Railroads take this responsibility seriously and have no higher priority than safety.

“The industry’s first goal is to prevent an accident before it can happen. The American Society of Civil Engineers (ASCE) gave rail its highest grade in its infrastructure report card in part because of the annual $20 billion in private investments in maintaining and improving network. At its core, a well-maintained railroad is a safe one, and thanks in part to those investments, rail remains the safest way to move hazmat over land.

“By the numbers:

- “99.9% of all hazmat shipments reach their destination without incident.

- “Since 2012, the hazmat accident rate has declined by 55%.

- “Over the past ten years, less than 1% of all train accidents have resulted in a hazmat release.

“Preparing and Protecting Communities: Railroads prioritize ensuring first responders have all the training and tools necessary to manage a potential rail incident safely. Each year, railroads train tens of thousands of first responders on how to safely manage a rail incident.

“The industry has also partnered with the International Association of Fire Chiefs to develop a mobile application—AskRail—that puts accurate, timely data to plan a swift, safe response. The app gives them immediate insight into railcar contents and recommended isolation zones, among other features. AskRail was used in response to the incident in Ohio.

“Additionally, railroads collaborate with local officials on emergency response plans in the rare event of an incident. Emergency response agencies can, upon request, receive confidential information on the hazmat moving through their communities.

“Cleanup and Remediation: Freight railroads work closely with first responders, state agencies and local officials to safely manage active rail incidents and mitigate potential impacts in accordance with their emergency response plans. Each railroad has full-time safety, environmental, and hazardous materials personnel who mobilize to manage the containment of spilled material and either remove or remediate it. These professionals work closely with state and federal environmental agencies such as the EPA to ensure full compliance with all state and federal regulations that include but are not limited to reporting, cleaning up the incident and completing an investigation into the root causes of the incident.”