CN: ‘Collaboration Drives Grain Supply Chain Results’

Written by Marybeth Luczak, Executive Editor

(CN Photograph)

“Working together with our supply chain partners, CN and its grain customers have achieved record or near-record results throughout the fall and winter shipping season,” CN reported March 24.

Heading into the 2022-23 crop year, CN said CEO Tracy Robinson pushed the railroad to get back to basics. “That meant running a scheduled operation, aligning capacity with demand, and working closely with our customers and stakeholders to maximize the effectiveness and efficiency of the full supply chain,” CN reported. “Our partners responded with more communication at the operational level and increased collaboration to resolve challenges when they arose. The result has been improved productivity and a more resilient grain supply chain.”

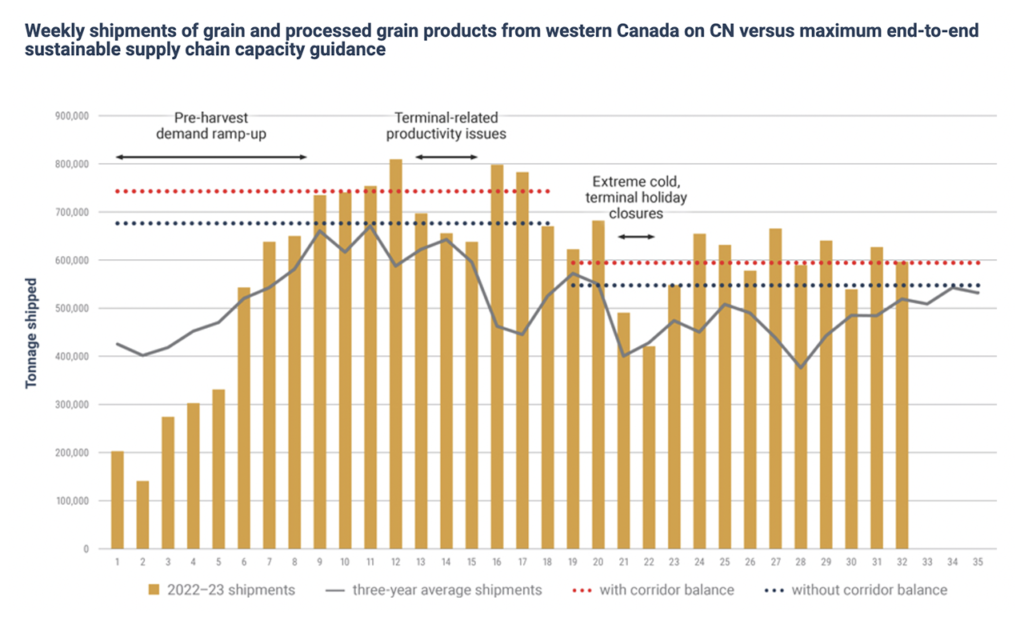

In its 2022-23 Grain Plan, released last summer, CN’s guidance to customers and grain supply chain stakeholders was that on a sustainable basis, CN could deliver up to 744,000 metric tons per week of shipments of grain and processed grain products outside of winter, and up to 595,000 metric tons per week during winter. “Being able to achieve those levels requires having all the conditions in place, including no mainline disruptions, fluidity across grain shipment corridors, normal winter operating conditions, and other considerations,” according to the Class I railroad. “For the most part, those conditions have been present.”

The railroad said it achieved record weekly grain shipment results in 12 of the first 32 weeks of the crop year. Additionally, February 2023 was the “best February ever” for Western Canadian grain movement, according to CN, which moved more than 2.4 million metric tons of grain over the course of the month and exceeded the previous record set in February 2021 by more than 200,000 metric tons.

At the half-way mark of the 2022-23 crop year, reported Feb. 10, CN had shipped more than 15.2 million metric tons (MMT) of grain and processed grain products from Western Canada. And through week 33 (March 12-18), it had moved 19.3 MMT—15% higher versus the average of the prior three years, and 53% above last year.

During the 2022-23 crop year, there have also been 18 weeks “where customer demand for grain movement was insufficient to meet grain supply chain capacity levels,” CN reported. “In the first eight weeks of the crop year, demand was low compared to normal due to limited carry-in stocks given the impact of drought on grain production in western Canada. January saw demand for CN equipment fall below normal levels due in part to the impact of record Australian grain productive affecting the relative competitiveness of western Canada in international markets.”

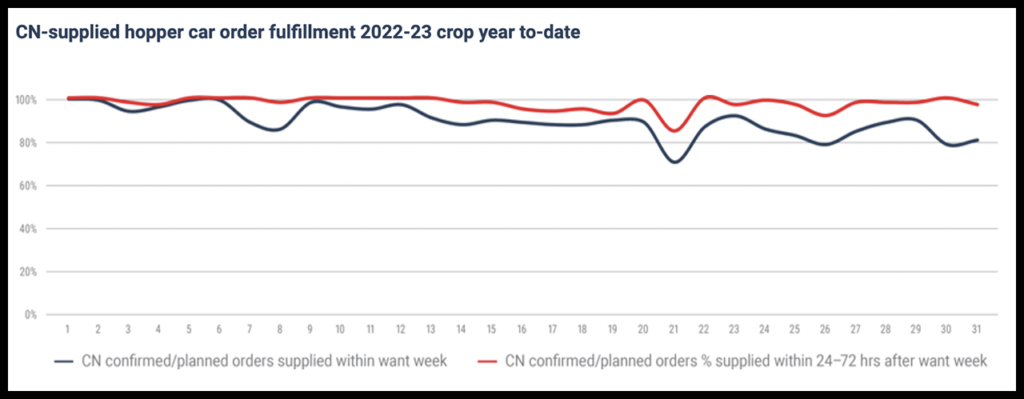

According to CN, it is not just about how much grain is moving every week. Consistency is key to customers and grain supply chain stakeholders. The railroad said it has been consistently supplying 90%-100% of planned and confirmed CN-supplied car orders within the week they were requested or within one to three days after the end of the want week, which translated into “strong and steady grain movement.”

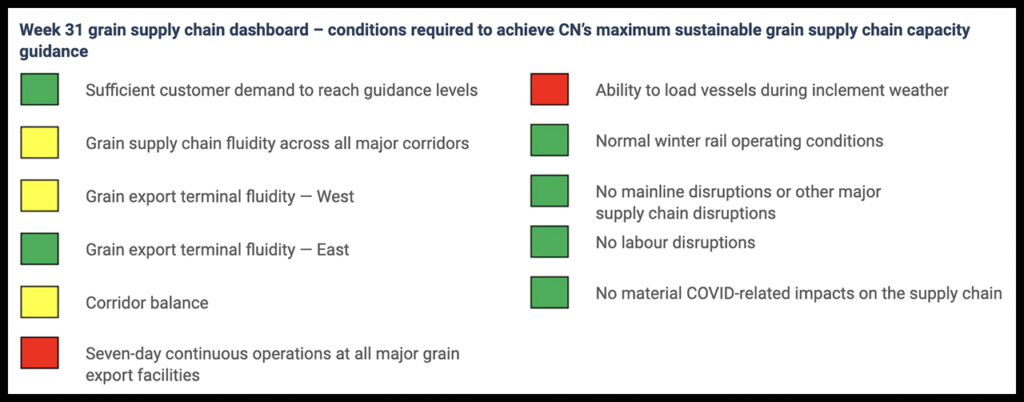

CN said it has provided a Weekly Western Canadian Grain Report since the 2016-17 crop year to get “into the ‘why’ of what’s going on in the supply chain.” Up front there is a supply chain dashboard, illustrating “how the supply chain is doing, and it ties back to all the conditions required to achieve maximum supply chain capacity,” according to the railroad.

CN said it also provides details about why the individual components of the dashboard are color-coded the way they are for that week. “The end-to-end supply chain is a lot more complicated than a 100% pass or fail exam,” according to the railroad. “All the links in the chain need to be working together to deliver results and each part of the supply chain needs to communicate with their partners to work through challenges when they arise. Loading delays at origin, a mainline disruption between the Prairies and the port, or vessel loading delays due to inclement weather at West Coast ports all have real impacts on the end-to-end supply chain.”

Additionally, the weekly grain supply chain reporting is packaged into CN’s monthly Grain Plan updates. “This document serves as a monthly record of what has been happening in the supply chain, relative to CN’s yearly Grain Plan and Winter Plan targets,” the railroad reported.