Value-Added Freight Car Service Outsourcing Challenges

Written by Jim Blaze, Contributing Editor

Trend Reminder: As always, this column represents Jim Blaze’s independent evaluation of trends and different rail freight vending companies. This column is about rail freight’s evolving software management tools. As a reminder, there are other providers competing out there. And some of the Class I railroads might disagree with my assessment that they can’t provide you with such value-added functionality. You, the railroad industry audience, must choose.

First mile/last mile, and the private car fleet management challenge: The Big Seven North American freight railroad carriers don’t handle personalized or customized business commerce with their customers. Starting in the 1980s, the large railroads encouraged outsourcing of such value coverage to outsiders—initially to short lines. How do I know? I watched it happen along my career.

It started with the spinoff of light-density branch lines when Conrail was created. It continued with other lightly trafficked physical lines and yards. The Class I’s had experimented with small geographic profit center accounting and small management efforts through past multiple decades. But substitution with outside providers like short lines took hold. It became the service pattern, creating centers of higher traffic development success than the big carriers could achieve.

Over the years that followed, small companies emerged to help rail shippers with everything from accounting to car tracking and fleet management. Each of those is a value enhancement beyond the Class I railway sector’s long-distance transportation function.

Software and communications R&D is now being advanced largely by outsiders. These “parties” are, for the most part, not actual railroad operating carriers. And with the half-century shift from when the railroad carrier provided general service pool cars for all customers to today’s rail freight world with more than 70% of the car fleets provided by private cars (either owned or leased by non-railroad companies), it is a logical outcome to see digital fleet management by such third-party vendors.

Given the so-called PSR Class I rail business model that emphasizes smaller balance sheet assets, it’s difficult for me as an investigative journalist and railroad economist to see a future that reverts to the business model where the big railroads can handle custom service.

Custom value adding is really the antithesis of the PSR inward corporate-focused business model that has resulted in service opportunities for others. So, if manufacturing or supply chain logistics are your core business competency, then ask yourself, “where can I store my freight cars while still managing their optimal use? Who’s helping me manage these expensive freight car fleets? Can I get a comprehensive package of such services from single providers? Who do I need to select as different vendors for different functions?

There are different providers out there, and some (if not all eventually) will be migrating their offerings. One of those is providers is Standard Rail. Here is part of a maturing story as the company is launching, within the month of August, an expanded service called Railcar Lounge™. At my request, they gave me a reporter’s sneak peek.

Standard Rail Corporation’s view of the private freight car world is that, in an ideal situation, shippers using private railcars would always have the ideal number of cars in circulation—not too many, not too few. The commodities they ship would have a steady demand market. The railroad companies would perform on time, and the car owners and their customers would never need to store a single railcar.

That’s not realistic. Thus, they must adapt to random cyclicality. Storage of both the railcars and often the loaded commodities inevitably become a factor in their daily supply chains. Disruption of car and “inventory in motion” is a fact of railroading life. And disruption is not always a railroad carriers’ fault. Other stuff happens within the shippers’ inventory and processing functions. From plant shutdowns to seasonal commodity cycles to dynamic changes in rail service, the need for railcar storage arises repeatedly, and sometimes quite suddenly. And since storage facilities often have some level of access to maintenance services, rail shippers are increasingly utilizing storage services for faster turnaround times for services such as cleaning, maintenance and repairs.

Standard Rail’s new Railcar Lounge™ software tool set “provides a more controlled and universal way to search for storage facilities that exactly matches the owners/shippers’ check list of services.” The Railcar Lounge™ team sees their tool as “a new way to help shippers procured these cross functional railcar storage services.” From their point of view, until now, railcar owners and operators would have to manually locate available storage locations suitable for their railcars, contact facilities to confirm availability, and then separately negotiate storage terms. Then they’d have to finalize the terms of a storage contract, procure and manage the insurance requirements for the term of the contract, and finally manually administer and manage this process through disconnected spreadsheets and emails.

That process is laborious and can take weeks or months to complete. It’s expensive. Standard Rail’s research suggests that these processes require the average railcar owners and operators as much as 80 staff hours. Sometimes it’s more expensive because they revert to using consultant hours to get the job wrapped up.

Railcar Lounge™ offers a new procedure. The digital desktop software product helps owners/operators privately negotiate rates directly with literally hundreds of geographically located regional storage yards. Each of those storage locations is an independent operator. The software links them together with the shipper/car owner looking to park their railcars. Once a deal for storage and servicing is in place, next comes the work to move the cars to the location from wherever they are. This and other car movement operations might take perhaps another 120-plus hours per month.

Railcar Lounge™ is built around eliminating those expenses. The approach is to help integrate all the Search, Select, Store and Manage functions within the software package.

Once the new storage arrangements are in place, next comes the digital processing of these command-and-control fleet “owner” movement functions, all overseen and controlled by a single platform:

- Manage sorting of “JIT” empty car movement orders.

- Privately car audit records.

- Periodic issuance of pull order plan and instructions.

Standard Rail is promoting Railcar Lounge™ as “a complete, integrated railcar storage management system” with “easy access using online connection with a secure proprietary system that allows customers to keep track of all their railcars at any storage facility on a single platform.” Customers “can find and select a storage facility and receive authorization quickly. That same platform provides them with audited standardized reports and invoices from all storage providers. All this information can be exchanged with Standard Rail’s systems security protocols.

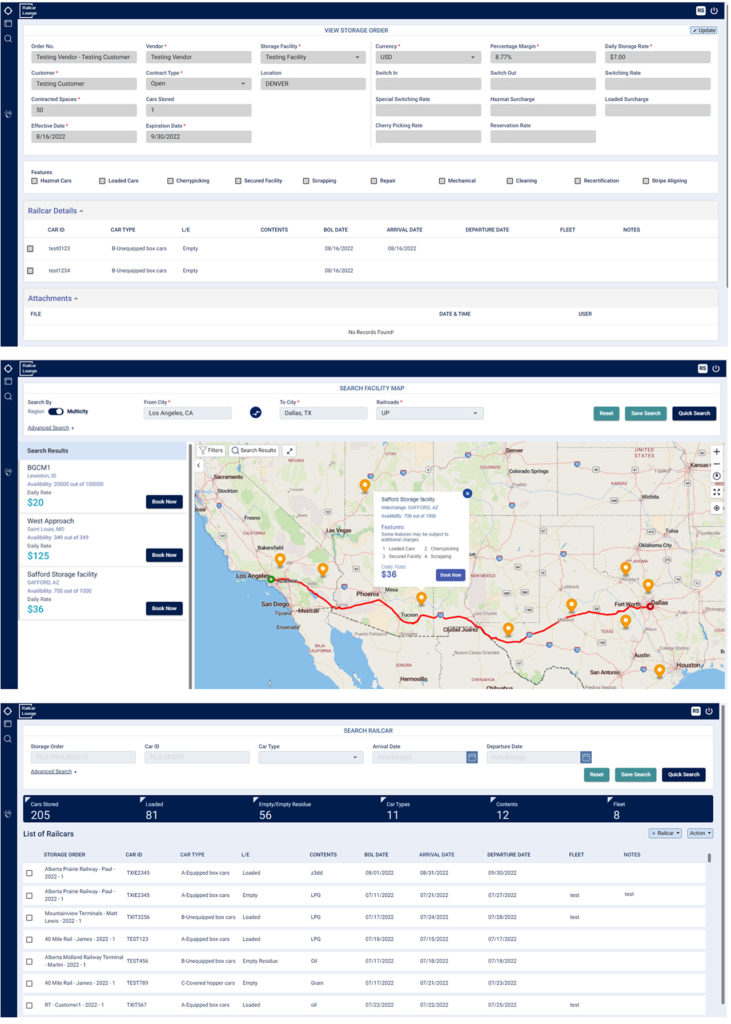

Here’s a selection of the types of desktop managerial screen shots that are part of the service. (Data contained is fictional for demonstration purposes.):

Those interested in learning more can access the website at http://www.standardrail.com/railcar-lounge. (Standard Rail™ Services and Railcar Lounge™ are trademarks of the Standard Rail Corporation, offered in Canada and the U.S. rail freight market region).

Independent railway economist and Railway Age Contributing Editor Jim Blaze has been in the railroad industry for more than 40 years. Trained in logistics, he served seven years with the Illinois DOT as a Chicago long-range freight planner and almost two years with the USRA technical staff in Washington, D.C. Jim then spent 21 years with Conrail in cross-functional strategic roles from branch line economics to mergers, IT, logistics, and corporate change. He followed this with 20 years of international consulting at rail engineering firm Zeta-Tech Associated. Jim is a Magna Cum Laude Graduate of St Anselm’s College with a master’s degree from the University of Chicago. Married with six children, he lives outside of Philadelphia. “This column reflects my continued passion for the future of railroading as a competitive industry,” says Jim. “Only by occasionally challenging our institutions can we probe for better quality and performance. My opinions are my own, independent of Railway Age. As always, contrary business opinions are welcome.”