2014 Railroad Financial Desk Book

Written by William C. Vantuono, Editor-in-ChiefIn last year’s Desk Book, the path forward was pretty clear, all eyes and minds were on the business of hydraulic fracking and the surge of Crude by Rail (CBR) and its impact on all sectors of the rail equipment industry. This year, the focus remains on CBR and the additional rail served requirements of hydraulic fracking, but the picture of CBR is clouded by the derailment of a 72-car train in Lac-Mégantic, Quebec and the deaths of 47 people from the resulting explosions and fire. Questions raised in the immediate wake of the tragedy remain unanswered, and their impact on CBR as yet undetermined. The question of potential regulatory changes in tank car design looms large considering the growth in CBR volumes on a year over year basis.

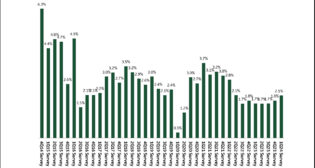

The year-over-year increases in CBR are staggering even to industry veterans. While the percentage represented by CBR of total North American rail loadings remains relatively low (3% in the 2nd quarter of 2013) the incredible growth and the growth potential continues to be the focus of the railcar backlog and of financial parties making investments in the industry. As Railway Age reported in July, tank cars represent 83% of the total current backlog for North American railcar production. Despite a small decrease in the total number of railcars to be built in 2013 vs. 2012 (roughly 59,000 in 2012 against an estimate of 52,500 for 2013), experts predict that the continued demand for tank cars plus growth in markets served by other car types (grain, steel, autos, etc.) will keep the railcar backlogs in the 60,000 units or more range for the remainder of this economic cycle.

One weak point in the railcar marketplace is the current market for coal equipment. Recent pronouncements from the EPA and President Obama against the building of new coal fired generating facilities and stating emissions limits on existing generating plants have not done anything to lift concerns about the fate of what has been one of the backbones of railroad loadings. Car prices are down, and in spite of a recent uptick in demand, rental rates remain low. This has impacted equipment values and will continue to impact construction of coal cars for the foreseeable future. Ultimately a mix of age, scrapping, and derailment related retirements will decrease that fleet to the size it needs to be to haul the coal that will continue to be shipped in the eastern and western U.S. for power generation, industrial production, and export . While a number of cars have moved back into service (at last count there were an estimated 151 mostly privately owned unit coal train cars sets in storage in the West and 24 unit coal train cars sets in storage in the East), supply still exceeds demand. (A unit train is a group of between 110-135 cars that comprise a single train. Coal trains tend to be shorter in the east and longer in the west.)

So how is 2014 shaping up for investors, owners, and operators of rail equipment? In the words of one lessor, the market today is tentative. The rental market has been and continues to be dichotomous: on the one hand, in spite of some modest pullbacks on some of the higher priced leases for CBR tanks, the tank car market overall remains robust for CBR and for other tank car types. Grain car lease rates (heading into what has the potential to be a record corn harvest and a strong soybean harvest) remain tepid. Small cube hopper cars, backed by the strength of hydraulic fracking, remain robust and in demand. Boxcars and mill gondola railcars seem to be in a midrange of not too strong and not too weak. Centerbeam flat cars, while off the floor, are still waiting for the economic housing boom that is going to return those cars to their former glory (many lessors would like see that also). Large cube hoppers for plastic pellets remain strong heading into a period of long term growth. Coal cars, as mentioned above, remain weak.

Up, down, or sideways?

The point is clear. A few markets, tanks and small cube hoppers primarily, are leading the manufacturing and rental markets. The remainder of the market is trending up, down, or sideways depending on the commodity and the timing. Broad-based, demand-driven strength in the manufacturing and lease market for all railcar types that historically has been the hallmark of a build year of greater than 50,000 railcars is not in evidence right now and is unlikely to make an appearance in the near term.

What does this say about equipment values and the market for investment in equipment? Logically, readers of this magazine might think that the market schism in rental rates is present in equipment values, as the fair market value would reflect the current rental market for the equipment. Sources have told us that fair market values for many types of equipment are high even for those assets serving weaker commodity markets. Investors in these assets may be anticipating forward economic strength that will allow those assets to deliver the expected return on investment. In addition, as Patrick Mazzanti, President of Railroad Appraisal Associates noted to me as I was preparing this article, “Replacement costs for new equipment are driving the used car market higher.”

New car pricing continues to be favorable to the manufacturers. The current price surge has been in place since railcar production increases began in earnest in late 2011. With new car production levels above the 50,000 car per year level and the railcar backlog out into 2015 for some car types, buyers of cars have little (if any) price leverage. In addition to a base cost that creates sticker shock for some buyers, new equipment buyers are bearing the risk of increases in commodity prices, component prices, and transportation rates. Add this together and it’s not hard to see why used car prices remain robust.

So we have a complex investment picture for parties that look to deploy capital into rail assets. Decisions about asset purchases and residuals are more difficult in a complex market. The difficulty of the environment is combined with a hyper-competitive market for investment. As noted in the 2013 Desk Book, banks and bank leasing companies were more frequently stepping into leases for equipment that were seven to ten years in length and in some cases even shorter. This puts the banks in the position of taking real residual risk on the assets they are financing. Taking residual risk has traditionally been the field of expertise for operating lessors. As interest rates rise over time (and the Federal Reserve tells everyone they will), what will the next “play” be for the banks and end users of rail equipment that have enjoyed access to the cheap money offered by the Federal Reserve?

The railroads also need to get their “props” as we contemplate the relative health of the industry overall. Railroad investments in infrastructure in 2012 were huge: $25.5 billion (or a total of almost $590 billion since 2000). These investments in track, signaling, terminals, and equipment continue to stoke the fires of the “Rail Renaissance.” These investments have supported and continue to support rail’s ability to take away market share in key growth markets (such as intermodal) vs. trucking and (bulk handling in certain grain markets) barging. Low interest rates are a strong positive behind the continued push for improvement. The ability to borrow at low rates along with the health of the railroad industry continues to drive interest and investment demand in railroads.

Overall, prospects for a positive 2014 seem in place. If the U.S. economy shows strength and the general freight market picks up, the combination of investments in infrastructure and increasing industrial capacity all bode well for equipment values, railcar production, and overall demand. (An improving global economy wouldn’t hurt either, but that remains to be seen.) Mix that with continued strength in the businesses serving and benefiting from CBR and hydraulic fracking, and you can enjoy the ongoing cyclical expansion and strength of this cycle in this great industry. Here’s to continued success for 2014.

Update on equipment financing

When 60,000 railcars get built, who pays for all of them? For 2012 and into 2013, the answer has been a little bit of everyone. Certainly, the majority of the financing opportunities went to the operating lessors, both those owned by the manufacturers and those that are stand alone entities. As referenced in the earlier article, 2013 was a coming of age for bank involvement in shorter term railcar leasing. Frequent readers of Railway Age’s “The Financial Edge” column have heard the news: Bank lenders have taken a long view of equipment and the rail marketplace and are making shorter term investments in equipment lease— sometimes taking on terms of less than seven years. For parties looking for the most cost effective solution, I hope that continues.

This is not to minimize the role that operating lessors are playing in this market. Some lessors, those who were savvy enough, sophisticated enough, or lucky enough (or all three) to make investments in cars on a speculative basis (speculative in this case means making commitments to purchase railcars without having leases in place prior to making a commitment to purchase) have been well rewarded. Other lessors, who have bought equipment and leases in the secondary market, have in many cases fared well also. Parties that made purchases of small-cube covered hoppers or tank cars coming off lease in 2012 or in 2013 have had reason to celebrate. Companies that made purchases of centerbeam flat cars or coal cars with similar expirations may wonder what they were thinking at the time of investment. The operating lessors are healthy overall. The number of companies looking to enter the leasing space certainly speaks to that.

So what’s new? Three things to watch as the railcar market moves forward into 2014:

• Number one: The impact of rising interest rates on the presence of banks in the shorter term leasing marketplace. How will they respond? By one back of the envelope calculation, an increase of 1% in treasury rates could equal an increase of $5.00 per car per month in lease rate from a lessor. A return to interest rate levels of 2005 (when the ten year treasury rate was as high as 4.6% versus 2.7% or so today), for example, may cause bank investors to reconsider their residual position to take a larger residual, to increase term to stay competitive, or to risk losing new business back to the operating lessors that commanded it in the first place.

• Number two: Concentration risk for CBR and the markets that serve the business of hydraulic fracking. At the Rail Equipment Finance conference in 2013, Thomas Ellman, EVP and President Rail North America for GATX Corp., noted the national tank car fleet required 10,000 cars at most (and less than 10,000 in most years) to be produced each year to replace cars that are destroyed or removed from service. Ellman went on to note that in the four-year window of 2012 through 2015, it is projected that roughly 74,000 tank cars will be built. The current backlog for tank cars supports this projection. Whether you are a casual investor or a direct lender into the energy space, all parties are aware of the uncertainty that surrounds pipeline development. It’s the multi-billion-dollar three part question: When will they be built, how much crude will they deliver, and how will it impact CBR? I don’t think you’ll find anyone, this writer included, who will tell you that CBR is a short term play. It would not surprise me, however to see some pullback from investors as aggregate residual exposure reaches high levels.

• Number three: The impact of rising interest rates on how railroads acquire equipment. The Class I railroads, profitable and flush with cash and the ability to use tax depreciation, have moved away from U.S.-based tax leasing as the pricing on their medium term notes (MTN) has been attractive enough to have them buy equipment outright. As rates and the total MTN costs rise, longer term leasing might return to favor, especially considering that the larger banks have had some time to manage down their exposure to marquee credits like TTX, UP, BNSF, CSX, and CP (lest anyone perceive a slight, NS and CN have historically been direct purchasers of equipment). Now, with the positive trend that has brought KCS in line with the credit quality of the other Class Is, there are plenty of opportunities for banks to look to the largest equipment buyers as potential lessees.

What’s the attraction? Besides the credit quality and the momentum enjoyed by the industry in general, the railroads are buyers of more universal equipment such as jumbo grain hoppers and mill gons, which may give some investors comfort in a CBR-centric environment. As one bank leasing veteran associate pointed out to me, it will be a perfect storm of opportunities for the railroads to pick and choose the manner in which they acquire equipment in a rising interest rate environment.

The fall brings with it the changing colors of the leaves, the onset of some cooler breezes, new hopes for the permanently purgatorial New York Jets fans, and a typical cadre of portfolio sales. I can’t comment on any of the first three, but I do note that the hope for increasingly high valuations shows the faith that underpins the market for rail equipment. The dollar volume of portfolio sales is a terrific barometer on the health of the industry. In good times there are always parties looking to “cash out” on purchases made at a good time or at a below market price. This year seems to be shaping up in similar fashion.

Who are the buyers in these big sales? The smart money tends to favor companies that have a history of taking strong residuals and making good on their valuation of those assets over time. Historically, those bets seem to pan out even if achieving the results takes a few extra years to work off the robust price associated with some acquisitions in a competitive market. As North American rail is an attractive sector in the domestic and foreign market, don’t rule out some new player with deep pockets looking to make a splash entrance into the rail financing pool. Keep your ear to the track: Large acquisitions are usually followed by some sales as asset pools are tailored to the liking of the new management team or to generate some cash to pay down some acquisition debt.

The regulatory environment for CBR tanks

One thing that is great about the railroad industry is that you frequently hear about the quality of the people. This writer has always found that to be true. It is certain that the tragedy in Lac-Mégantic, Quebec, gave the entire industry pause as the industry and the people that derive their livelihood from it take safety very seriously. That concern for safety is spearheading the efforts to determine how to insure the safest environment for tank cars and CBR. The growth potential and longevity of CBR require defining the best manner in which to handle any changes in tank design that may be necessary.

In spite of how tragic the events in Lac-Mégantic were, the derailment offers no concrete advice on changes that may be required in tank car design. I have spoken with industry veterans that ship all types of commodities, including TIH (toxic inhalation hazard) commodities across the nation. To paraphrase what has been communicated to me, derailments at 70 mph are extremely rare and there is no car being built today that could withstand the impact force of a collision at that speed. In last year’s Desk Book, there was an article about the change in tank car design for the standard CBR car. It is possible that the current car design might be the long term designated car type for CBR. It is possible that the car design will be modified or refined to add additional safety enhancements. Cars that do not meet the current standard, including having the correct thickness of the steel at the head of the tank, may be restricted from CBR service entirely, but one would expect at the least a limitation on their use in CBR (or ethanol) unit train service.

From what we hear in the market, there does not seem to be support for a jacketed car (a tank surrounded by insulation and a second metal shell) and its impact on the national fleet or total fleet efficiency. Implementation of a jacketed car design would be a lengthy and expensive process. The tank car committee providing recommendations on changes in design that might be implemented by the FRA gives fair and careful consideration to all aspects of the issue, from derailments caused by human error (as seems to be the conclusion in Quebec) to derailments caused by track conditions to the potential for avoidance of future tank puncturing.

From the outside looking in, the events in Quebec do not seem to have caused a shift in the momentum for pipeline implementation. Here’s the tie in between the events in Quebec and the marketplace for tank cars. As investors in railcars and especially in tank cars contemplate their next steps, there are certainly concerns about the potential for overbuilding. These concerns exist, as they would in any tight market, in an industry that chronically overbuilds during strong economic cycles. The impact of pipelines for crude and regulatory changes that may occur is not yet known. For leasing and finance veterans, it’s part of the ballet that goes on as the industry moves through five- or six-year economic cycles. Most of them adopt a “Keep Calm and Carry On” attitude as they work to do the best for their companies. These veterans may decide that the exposure is too great and pull back on investment. In the mean time, adopting their current approach sounds like pretty good advice.